Abstract

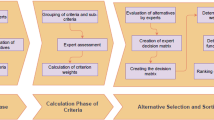

By constructing a Smart energy efficient manufacturing (SEEM) process grey model, craft parameter optimization is transformed into the process of multi-attribute decision making. Using fuzzy set theory to deal with uncertainty and inaccuracy fuzzy knowledge of SEEM assessment experts, a directly effect incidence matrix and a comprehensive effect matrix of SEEM process are put forward to be indexed by Trial and evaluation laboratory (TEL). The central degree and causal degree of each evaluation index are obtained, and then the relevance is analyzed between SEEM process evaluation indicators and weighted according to impact degrees. At the premise of maximizing of population benefits and minimizing of individual regret, the SEEM process parameters are determined by TEL-VIKOR theory. To obtain SEEM process parameters or compromise process parameters, a decision maker's subjective preference, and establishing control priorities of best SEEM process parameters are set. Finally, SEEM process parameters making decision example from discharge manufacturing process are applied to verify the proposed method.

Similar content being viewed by others

References

J. Y. Kao et al., Optimization of the EDM parameters on machining Ti-6Al-4V with multiple quality characteristics, International J. of Advanced Manufacturing Technology, 47 (2010) 395–402.

S. P. Sivapirakasam, J. Mathew and M. Surianarayanan, Multi-attribute decision making for green electrical discharge machining, Expert Systems with Applications, 38 (2) (2011) 8370–8374.

R. V. Rao and P. J. Pawar, Parameter optimization of a multi-pass milling process using non-traditional optimization algorithms, Applied Soft Computing, 10 (10) (2010) 445–456.

C. J. Lin and W. W. Wu, A causal analytical method for group decision-making under fuzzy environment, Expert Systems with Applications, 34 (1) (2008) 205–213.

Y. U. Jiashan, The principle of electrical discharge machining, Beijing: National Defence Industry Press (2011).

F. Lin, C. C. Yeh and M. Y. Lee, The use of hybrid manifold learning and support vector machines in the predicition of business failure, Knowledge-Based System, 24 (1) (2011) 95–101.

G. B. Koksal and M. C. Testik, A review of data mining application for quality improvement in manufacturing industry, Expert Systems with Applications, 38 (2011) 13448–13467.

J. Harding, M. Shahbaz and A. Kusiak, Data mining in manufacturing: A review, J. of Manufacturing Science and Engineering, 128 (2006) 969–976.

X. Q. Tang and X. C. Wang, Customer-oriented quality improvement in mass customization, Chinese J. of Mechanical Engineering, 41 (5) (2015) 200–204.

V. N. Vapnik, The nature of statistical learning theory, New York: Springer (2000).

Y. Gao, Z. Liu and D. Hu, Selection of greem product design scheme based on multi-attribute decision-making method, International J. of Sustainable Engineering, 3 (4) (2013) 277–291.

X. H. An, Y. X. Feng and J. R. Tan, Planning method for supplier-involved product concept based on multi-objective optimization and multi-attribute decition, J. of Mechanical Engineering, 48 (1) (2012) 119–127.

M. T. Chu et al., Comparison among three analytical methods for knowledge communities group-decision analysis, Expert Systems with Applications, 33 (4) (2007) 1011–1024.

F. Peder and S. C. Joyce, Life-cycle modeling for adaptive and variant design, Research in Engineering Design, 15 (4) (2013) 216–241.

I. Prebil, S. Zupan and P. Lučič, Adaptive and variant design of rotational connections, Engineering with Computers, 11 (2) (2013) 83–93.

X. Renaud, Implicit uncertainty propagation for robust collaborative optimization, Proceedings of DETC’01, ASME 2010 Design Engineering Technical Conferences and Computers and Information in Engineering Conference, CD-ROM Proceedings, Pittsburgh, Pennsylvania, September 9-12 (2011).

J. E. Fowler, Variant design for mechanical artifacts: A state of the art survey, Engineering With Computers, 12 (1) (2006) 1–15.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Haedo Jeong

Wei Zhe is the senior member of CMES, Associate Professor of Northeastern University. He received his Ph.D. in Mechanical Engineering from Zhejiang University, China, in 2009. His current research interests are production engineering and mechanical engineering.

Yixiong Feng received the B.S. and M.S. in Mechanical Engineering from Yanshan University, Qinhuangdao, China, in 1997 and 2000, the Ph.D. in Mechanical Engineering from Zhejiang University, Hangzhou, China, in 2004. He is currently a Professor of Mechanical Engineering of Zhejiang University, China and the member of the State Key Lab of Fluid Power Transmission and Control of Zhejiang University, China. His research focuses on mechanical product design theory, intelligent automation and advance manufacture technology.

Zhaoxi Hong received the M.S. in Mechatronic Engineering from China University of Mining and Technology, Xuzhou, China, in 2016. She is currently a Ph.D. student at Zhejiang University, Hangzhou, China and a member of the State Key Lab of Fluid Power Transmission and Control of Zhejiang University, China. Her research focuses on low carbon mechanical product design theory and product reliability apportionment theory.

Jianrong Tan has an M.S. in Engineering and Ph.D. in Science and is a Specially- appointed Professor of the State Key Laboratory of Fluid Power and Mechatronic Systems, Zhejiang University, Hangzhou, China. He is mainly engaged in Mechanical Design and Theory, Research in Digitalized Design and Manufactory University, Tutoring Board of the Minister of Education.

Rights and permissions

About this article

Cite this article

Zhe, W., Yixiong, F., Zhaoxi, H. et al. A TEL decision method of process parameters for smart energy efficient manufacturing. J Mech Sci Technol 31, 3897–3905 (2017). https://doi.org/10.1007/s12206-017-0735-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0735-7