Abstract

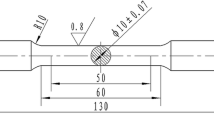

The cold ring rolling of GCr15 steel was carried out for achieving the grain refinement and texture of bearing ring blanks while causing plastic deformation within the matrix. The degree of grain refinement was significantly increased by enlarging the rolled deformation. The plastic damage of bearing ring blanks was correlated with the degree of grain refinement. The rolled plastic deformation was an influential factor with crucial effects on the texture evolution. These results obtained provide valuable guidance for revealing the relationship of the microstructure of bearing ring blanks with the process of cold ring rolling.

Similar content being viewed by others

References

J. Chakraborty and I. Manna, Development of ultra?ne ferritic sheaves/plates in SAE 52100 steel for enhancement of strength by controlled thermomechanical processing, Materials Science and Engineering A, 548 (2012) 33–42.

N. Luzginova, L. Zhao and J. Sietsma, Evolution and thermal stability of retained austenite in SAE 52100 bainitic steel, Materials Science and Engineering A, 448 (2007) 104–110.

L. Rogal, G. Korpala and J. Dutkiewicz, Evolution of microstructure in 100Cr6 steel after cooling from a thixoforming temperature to bainitic transformation ranges, Materials Science and Engineering A, 624 (2015) 291–299.

K. Ryttberg, M. K. Wedel, P. Dahlman and L. Nyborg, Microstructural evolution during fracture induced by high strain rate deformation of 100Cr6 steel, J. of Materials Processing Technology, 209 (2009) 3325–3334.

C. X. Yue, L. W. Zhang, J. H. Ruan and H. J. Gao, Modelling of recrystallization behavior and austenite grain size evolution during the hot rolling of GCr15 rod, Applied Mathematical Modelling, 34 (2010) 2644–2653.

J. J. Sun, F. L. Lian, H. J. Liu, T. Jiang, S. W. Guo, L. X. Du and Y. N. Liu, Microstructure of warm rolling and pearlitic transformation of ultrafine-grained GCr15 steel, Materials Characterization, 95 (2014) 291–298.

X. H. Han, L. Hua, G. H. Zhou, B. H. Lu and X. K. Wang, FE simulation and experimental research on cylindrical ring rolling, J. of Materials Processing Technology, 214 (2014) 1245–1258.

X. H. Han, L. Hua, G. H. Zhou, B. H. Lu and X. K. Wang, A new cylindrical ring rolling technology for manufacturing thin-walled cylindrical ring, International J. of Mechanical Sciences, 81 (2014) 95–108.

S. D. Gu, L. W. Zhang, C. X. Yue, J. H. Ruan and J. L. Zhang, Multi-field coupled numerical simulation of microstructure evolution during the hot rolling process of GCr15 steel rod, Computational Materials Science, 50 (2011) 1951–1957.

K. Ryttberg, M. K. Wedel, V. Recina, P. Dahlman and L. Nyborg, The effect of cold ring rolling on the evolution of microstructure and texture in100Cr6 steel, Materials Science and Engineering A, 527 (2010) 2431–2436.

L. Hua, D. S. Qian and L. B. Pan, Analysis of plastic penetration in process of groove ball-section ring rolling, J. of Mechanical Science and Technology, 22 (2008) 1374–1382.

A. Leiro, A. Kankanala, E. Vuorinen and B. Prakash, Tribological behaviour of carbide-free bainitic steel under dry rolling/sliding conditions, Wear, 273 (2011) 2–8.

A. Loorentz and G. Y. Ko, Effect of differential speed rolling strain on microstructure and mechanical properties of nanostructured 5052 Al alloy, J. of Alloys and Compounds, 586 (2014) 205–S209.

M. Kamaya, J. Q. D. Fonseca, L. M. Li and M. Preuss, Local plastic strain measurement by EBSD, Applied Mechanics and Materials, 7-8 (2007) 173–179.

M. Kamaya, Characterization of microstructural damage due to low-cycle fatigue by EBSD observation, Materials Characterization, 60 (2009) 1454–1462.

L. Hua and Z. Z. Zhao, The extremum parameters in ring rolling, J. of Materials Processing Technology, 69 (1997) 273–276.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Dae-Cheol Ko

Song Deng received his Ph.D. in Vehicle Engineering from Wuhan University of Technology, China, in 2014. His research areas include fatigue damage mechanisms on the automotive components and their applications.

Dongsheng Qian received his Ph.D. in Mechanical Engineering from Wuhan University of Technology, China, in 2009. Qian is currently an Associate Professor of Materials Science and Engineering, Hubei Key Laboratory of Advanced Technology of Automotive Components at Wuhan University of Technology, China.

Rights and permissions

About this article

Cite this article

Deng, S., Qian, D. Grain refinement-plastic deformation-texture of bearing ring blank in cold ring rolling. J Mech Sci Technol 31, 2965–2973 (2017). https://doi.org/10.1007/s12206-017-0540-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0540-3