Abstract

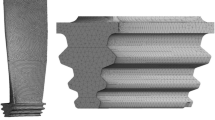

In this study, the phenomenological lifetime model was applied to part of an ultra-supercritical steam turbine rotor model to predict its lifetime as a post processing of the finite element method. To validate the accuracy and adaptation of the post processing program, stress-strain hysteresis loops of a cylinderal model under service-like load cycle conditions in cycle N = 1 and 300 were constructed, and the comparison of the results with experimental data on the same cylinderal specimen showed them to be satisfactory. The temperature and von Mises stress distributions of the rotor during a startup-running-shutdown-natural cool process were numerically studied using ABAQUS and the damage caused by the interaction of creep and fatigue was subsequently computed and discussed. It was found that the maximum damage appeared at the inlet notch zone, with the blade groove areas and the front notch areas also suffering a large damage amplitude.

Similar content being viewed by others

References

R. H. Priest and E. G. Ellison, A combined deformation map-ductility exhaustion approach to creep-fatigue analysis, Materials Science and Engineering, 49 (1) (1981) 7–17.

T. Lehmann, The Constitutive Law in Thermoplasticity, Springer (281) (1984).

S. S. Manson, G. R. Halford and R. E. Oldrieve, Relation of cyclic loading pattern to microstructural fracture in creep fatigue (1983).

J. L. Chaboche, Constitutive equations for cyclic plasticity and cyclic viscoplasticity, International Journal of Plasticity, 5 (3) (1989) 247–302.

J. P. Jing et al., An effective continuum damage mechanics model for creep–fatigue life assessment of a steam turbine rotor, International Journal of Pressure Vessels and Piping, 80 (6) (2003) 389–396.

A. Scholz and C. Berger, Deformation and life assessment of high temperature materials under creep fatigue loading, Materialwissenschaft und Werkstofftechnik, 36 (11) (2005) 722–730.

E. L. Robinson, Effect of temperature variation on the longtime rupture strength of steels, Trans. ASME, 74 (5) (1952) 777–781.

S. Taira, Lifetime of structures subjected to varying load and temperature, Creep in Structures, Springer Berlin Heidelberg, (1962) 96–124.

L. Cui et al., The influence of temperature transients on the lifetime of modern high-chromium rotor steel under servicetype loading, Materials Science and Engineering: A, 560 (2013) 767–780.

P. Wang et al., Multiaxial thermomechanical creep-fatigue analysis of heat-resistant steels with varying chromium contents, International Journal of Fatigue, 67 (2014) 220–227.

L. Cui and P. Wang, Two lifetime estimation models for steam turbine components under thermomechanical creep–fatigue loading, International Journal of Fatigue, 59 (2014) 129–136.

L. Stefan and A. Scholz, Creep-fatigue lifetime assessment with phenomenological and constitutive material laws, Procedia Engineering, 55 (2013) 607–611.

W. Ramberg and W. R. Osgood, Technical Report No. 902 (1943).

F. H. Norton, The creep of steel at high temperatures. No. 35, McGraw-Hill Book Company, Incorporated (1929).

J. Granacher, A. Scholz and C. Berger, Creep fatigue behaviour of heat resistant turbine rotor steels under service-type strain cycling, Advances in Turbine Materials, Design and Manufacturing (1997) 592–602.

J. Granacher and A. Scholz, Creep-fatigue behavior of heat resistant steels under service-type long-term conditions, Low Cycle Fatigue and Elasto-Plastic Behavior of Materials—3, Springer Netherlands (1992) 235–241.

F. R. Larson and J. Miller, A time-temperature relationship for rupture and creep stresses (1952).

K. N. Smith, T. H. Topper and P. Watson, A stress-strain function for the fatigue of metals (Stress-strain function for metal fatigue including mean stress effect), Journal of Materials, 5 (1970) 767–778.

S. Zhang and M. Sakane, Multiaxial creep–fatigue life prediction for cruciform specimen, International Journal of Fatigue, 29 (12) (2007) 2191–2199.

M. Schwienheer et al., Long term creep and creep fatigue properties of the martensitic steels of type (G) X12CrMoWVNbN10-1-1, Proc. of the 7th COST Conference Materials for Advanced Power Engineering (2002) 1409.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Nam-Su Huh

Nailong Zhao was born in China in 1990. He received the bachelor degree in energy power system and automation from Xi’an Jiaotong University, Xi’an, China, in 2013. He is currently working towards the Ph.D. degree in power engineering and engineering thermophysics from Shanghai Jiaotong University, Shanghai, China. His major areas are lifetime and structural integrity asessment of high-temperature components.

Weizhe Wang is an Associate Professor at Institute of Turbomachinery / Gas Turbine Research Institute, School of Mechanical Engineering, Shanghai Jiao Tong University. His research areas are structural analysis of high-temperature components, constitutive model, and integrity of component.

Rights and permissions

About this article

Cite this article

Zhao, N., Wang, W., Jiang, J. et al. Study of creep-fatigue behavior in a 1000 MW rotor using a phenomenological lifetime model. J Mech Sci Technol 31, 605–614 (2017). https://doi.org/10.1007/s12206-017-0113-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-0113-5