Abstract

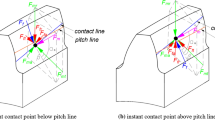

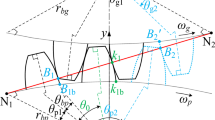

Due to either elastic deformations or errors in the manufacturing or assembling of gears, shafts, bearings and their housings, it is an inevitable consequence that mesh misalignment between teeth occurs. The change in length of the contact line or the change in load distribution along the length of the contact line induced by mesh misalignment causes changes in the dynamic characteristics of helical gears. There is currently no satisfactory solution for the modeling and calculation of the internal excitation in helical gears with mesh misalignment and sliding friction that would reveal the changes in the dynamic characteristics. In this study, an improved calculation method of friction excitation is proposed based on the time-varying length of the contact line and the time-varying friction coefficient model in helical gears. By considering the change in the mesh position and the change in the length of the contact line or the change of the displacement error along the contact line induced by mesh misalignment, the time-varying sliding friction force and the dynamic mesh force may be obtained. An eight degree-of-freedom analytical helical gear pair model is developed by incorporating the time-varying sliding friction force and dynamic mesh force and considering the mesh misalignment. By assuming a constant mesh stiffness density along the contact line, the rules governing the variation of the dynamic response are obtained using simulations of helical gear pair examples with different friction coefficient models and mesh misalignment. The developed analytical model provides a new method for the study of excitation characteristics in helical gears with mesh misalignment.

Similar content being viewed by others

References

D. R. Houser, J. Harianto and D. Talbot, Gear mesh misalignment, Gear Solutions, 6 (2006) 34–43.

T. Koide, S. Oda, S. Matsuura and A. Kubo, Equivalent misalignment of gears due to deformation of shafts, bearings and gears, JSME International Journal Series C, 46 (4) (2003) 1563–1571.

V. Roda-Casanova, J. L. Iserte-Vilar, F. Sanchez-Marin, A. Fuentes-Aznar and I. Gonzalez-Perez, Development and comparison of shaft-gear models for the computation of gear misalignments due to power transmission, ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (2011) 279–287.

S. Li, Effects of machining errors, assembly errors and tooth modifications on loading capacity, load-sharing ratio and transmission error of a pair of spur gears, Mechanism and Machine Theory, 42 (2007) 698–726.

M. Hotait and A. Kahraman, Experiments on root stresses of helical gears with lead crown and misalignments, Journal of Mechanical Design, 130 (2008) 1–5.

A. Artoni, M. Guiggiani, A. Kahraman and J. Harianto, Robust optimization of cylindrical gear tooth surface modifications within ranges of torque and misalignments, Journal of Mechanical Design, 135 (12) (2013) 1–9.

N. Driot and J. Perret-Liaudet, Variability of modal behavior in terms of critical speeds of a gear pair due to manufacturing errors and shaft misalignments, Journal of Sound and Vibration, 292 (2006) 824–843.

J. D. Smith, Helical gear vibration excitation with misalignment, Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 208 (1994) 71–79.

T. C. Lim and J. Wang, Effects of assembly errors on hypoid gear mesh and dynamic response, ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (2005) 801–806.

S. He, R. Gunda and R. Singh, Effect of sliding friction on the dynamics of spur gear pair with realistic time-varying stiffness, Journal of Sound and Vibration, 301 (2007) 927–949.

C. Gill-Jeong, Analysis of the nonlinear behavior of gear pairs considering hydrodynamic lubrication and sliding friction, Journal of Mechanical Science and Technology, 23 (2009) 2125–2137.

G. Liu and R. G. Parker, Impact of teeth friction and its bending effect on gear dynamics, Journal of Sound and Vibration, 320 (2009) 1039–1063.

J. Borner and D. R. Houser, Friction and bending moments as gear noise excitations, SAE Transaction, 105 (6) (1996) 1669–1676.

C. Kar and A. R. Mohanty, An algorithm for determination of time-varying frictional force and torque in a helical gear system, Mechanism and Machine Theory, 42 (2007) 482–496.

P. Velex and P. Sainsot, An analytical study of teeth friction excitations in errorless spur and helical gears, Mechanism and Machine Theory, 37 (2002) 641–658.

S. He, R. Gunda and R. Singh, Inclusion of sliding friction in contact dynamics model for helical gears, Journal of Mechanical Design, 129 (2007) 48–57.

I. Howard, S. Jia and J. Wang, The dynamic modelling of a spur gear in mesh including friction and crack, Mechanical Systems and Signal Processing, 15 (5) (2001) 831–853.

H. Jiang, Y. Shao and C. K. Mechefske, Dynamic characteristics of helical gears under sliding friction with spalling defect, Engineering Failure Analysis, 39 (2014) 92–107.

H. Xu, A. Kahraman, N. E. Anderson and D. G. Maddock, Prediction of mechanical efficiency of parallel-axis gear pairs, Journal of Mechanical Design, 129 (1) (2007) 58–68.

A. Z. Szeri, Fluid film lubrication: Theory and design, Cambridge University Press, UK (2005).

X. Liu, Involute cylindrical gear, China Planning Press, China (2004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Ohseop Song

Hanjun Jiang is currently a Ph.D. student at State Key Laboratory of Mechanical Transmission, Chongqing University, Chongqing, China. He spent two years as a visiting scholar at The Ohio State University to conduct research in gear vibration and noise. His research interests include gear dynamics and fault diagnosis.

Yimin Shao received his Ph.D. from Gunma University (Japan) in 1997. He is now a professor at the State Key Laboratory of Mechanical Transmission, Chongqing University, Chongqing, China. His research interests include the signal processing, the pattern recognition and the machinery fault diagnosis.

Chris K. Mechefske is a full Professor in the Department of Mechanical and Materials Engineering at Queen’s University in Kingston, Ontario, Canada. His research interests include vibration based machine condition monitoring and fault diagnostics, maintenance and reliability, machine dynamic analysis, biomechanics of artificial limbs, vibration and noise reduction in and around biomedical equipment. He is a member of the editorial board of the Journal of Condition Monitoring and Diagnostic Engineering Management; Canadian Advisory Council, ISO Technical Committee 108, Sub-Committee 5; American Society of Mechanical Engineers; Canadian Machinery Vibration Association (past president 2003-2005); and the International Institute of Acoustics and Vibration (Director 2007-2009).

Xiaohui Chen received her Ph.D. from Chongqing University, China. She is now a professor at the State Key Laboratory of Mechanical Transmission, Chongqing University, Chongqing, China. Her research interests include equipment maintenance and management.

Rights and permissions

About this article

Cite this article

Jiang, H., Shao, Y., Mechefske, C.K. et al. The influence of mesh misalignment on the dynamic characteristics of helical gears including sliding friction. J Mech Sci Technol 29, 4563–4573 (2015). https://doi.org/10.1007/s12206-015-1001-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-1001-5