Abstract

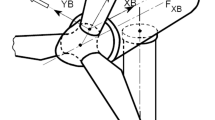

We evaluated the performance and fatigue life of a pitch bearing for multi-megawatt wind turbine. The test pitch bearing was a fourpoint contact ball bearing of internal-gear type designed to meet all specifications required for wind turbine pitch bearings. The tests used a test rig capable of reproducing the operational environment of pitch bearings, and the test items were selected on the basis of the actual operational conditions of the pitch bearing: a performance test to investigate friction torque and stiffness characteristics under extreme loads, and a fatigue life test to investigate friction torque and raceway surface temperature characteristics under fatigue loads.

As test results, the friction torque of the pitch bearing was within the theoretically expected range, and stiffness characteristics also coincided well with the known trend for ball bearings. In addition, the raceway surface temperature barely changed in the operational temperature range; thus, it can be concluded that the pitch bearing has worked satisfactorily without losing its functionality under the regulated extreme and fatigue loading conditions.

Similar content being viewed by others

References

T. Burton, D. Sharpe, N. Jenkins and E. Bossanyi, Wind energy handbook, John Wiley & Sons Inc., West Sussex, UK (2001).

J. Brandlein, P. Eschmann, L. Hasbargen and K. Weigand, Ball and roller bearings, 3rd ed, Wiley Ltd., West Sussex, UK (1999).

J. S. Nam, J. W. Han, Y. J. Park, Y. Y. Nam and G. H. Lee, Development of highly reproducible test rig for pitch and yaw bearings of wind turbine, JMST, 28 (2014) 705–712.

S. Martin, Stress analysis and modal analysis of the largest bearing test rig in the world — Astraios, Simulia Community Conference, Rhode Island, USA (2012).

MTS wind power solutions, Improving Reliability through Mechanical Testing & Simulation, MTS, Eden Prairie, USA (2012).

PSL, Quality for Heavy Duty, Ohio, USA (2009).

Germanischer Lloyd, Guideline for the certification of wind turbine, 2010 Ed., GL, Hamburg, Germany (2010).

Wind turbine design guideline DG03, Yaw and Pitch Rolling Bearing Life, Technical report NREL/TP-500-42362, NREL, Colorado, USA (2009).

A. Daidie, Z. Chaib and A. Chosn, 3D simplified finite elements analysis of load and contact angle in a slewing ball bearing, J. of Mechanical Design, 130 (2008) 1–8.

T. Smolnicki, M. Stanco and D. Pietrusiak, Distribution of loads in the large-size bearings—problems of identification, Technical Gazette, 20 (2013) 831–836.

X. H. Gao, X. D. Huang, H. Wang and J. Chen, Modellingof ball-raceway contacts in a slewing bearing with non-linear springs, Proceedings of the Institution of Mechanical Engineers, Part C: J. of Mechanical Engineering Science, 225 (2011) 827–831.

E. Errichello and J. Muller, Gearbox reliability collaborative gearbox 1 failure analysis report, Subcontract report NREL/SR-5000-53062, National Renewable Energy Laboratory, Colorado, USA (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Moon Ki Kim

Jeong Woo Han received his B.S. and M.S. in Mechanical Engineering from Inha University, Korea, in 1992 and 1994, respectively. His Ph.D. in Mechanical Design Engineering is from Chungnam National University, Korea, in 2005. He is currently a principal researcher at the Dept. of System Reliability of KIMM. His research interests are in structural safety and experimental fatigue strength assessment.

Young Jun Park has been working at Korea Institute of Machinery & Materials (KIMM) in Daejeon, Korea, since 2006. He is interested in design and analysis of gearboxes and bearings for wind turbine and construction equipment. He received a B.S., an M.S., and a Ph.D. in Agricultural Machinery Engineering from Seoul National University, Korea.

Rights and permissions

About this article

Cite this article

Han, J.W., Nam, J.S., Park, Y.J. et al. An experimental study on the performance and fatigue life of pitch bearing for wind turbine. J Mech Sci Technol 29, 1963–1971 (2015). https://doi.org/10.1007/s12206-015-0417-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-0417-2