Abstract

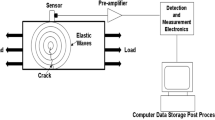

Current steel tubes inspection techniques are invasive, and the interpretation and evaluation of inspection results are manually done by skilled personnel. This paper presents a statistical analysis of high frequency stress wave signals captured from a newly developed non-invasive, non-destructive tube inspection technique known as the vibration impact acoustic emission (VIAE) technique. Acoustic emission (AE) signals have been introduced into the ASTM A179 seamless steel tubes using an impact hammer, and the AE wave propagation was captured using an AE sensor. Specifically, a healthy steel tube as the reference tube and four steel tubes with through-hole artificial defect at different locations were used in this study. The AE features extracted from the captured signals are rise time, peak amplitude, duration and count. The VIAE technique also analysed the AE signals using statistical features such as root mean square (r.m.s.), energy, and crest factor. It was evident that duration, count, r.m.s., energy and crest factor could be used to automatically identify the presence of defect in carbon steel tubes using AE signals captured using the non-invasive VIAE technique.

Similar content being viewed by others

References

J. H. Bulloch, A. G. Callagy, S. Scully and A. Greene, A failure analysis and remnant life assessment of boiler evaporator tubes in two 250 MW boilers, Eng. Fail. Anal., 16 (2009) 775–793.

S. Cicero, R. Lacalle, R. Cicero and J. García, Failure analysis of a steam generator superheater drain tube used in a dump, Eng. Fail. Anal., 17 (2010) 301–312.

S. R. Allahkaram, P. Zakersafaee and S. A. M. Haghgoo, Failure analysis of heat exchanger tubes of four gas coolers, Eng. Fail. Anal., 18 (2011) 1108–1114.

A. S. Birring, Selection of NDT techniques for inspection of heat exchanger tubing, Proc. of ASNT International Conference on Petroleum Industry Inspection, Houston, TX. (1999) 1–14.

B. Yang and X. Li, Pulsed remote field technique used for nondestructive inspection of ferromagnetic tube, NDT E Int., 53 (2013) 47–52.

A. Erhard, X. Schuler and F. Otremba, A new concept for steam generator tube integrity assessment, Nucl. Eng. Des., 249 (2012) 297–303.

N. J. Carino, Training: Often the missing link in using NDT methods, Constr. Build. Mater., 38 (2013) 1316–1329.

M. J. Mahjoob, A. Shahsavari and A. Marzban, A vibrationbased damage detection method for pipes conveying fluid, Proc. of 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, Hawaii (2007) 7799–7806.

J. J. da Silva, A. M. N. Lima, F. H. Neff and J. S. da R. Neto, Non-invasive fast detection of internal fouling layers in tubes and ducts by acoustic vibration analysis, IEEE Trans. on Instrum. Meas., 58 (2009) 108–114.

M. Shehadeh, J. A. Steel and R. L. Reuben, Acoustic emission source location for steel pipe and pipeline applications: The role of arrival time estimation, Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng., 220 (2006) 121–133.

Q. Ai, C.-X. Liu, X.-R. Chen, P. He and Y. Wang, Acoustic emission of fatigue crack in pressure pipe under cyclic pressure, Nucl. Eng. Des., 240 (2010) 3616–3620.

A. Mostafapour and S. Davoudi, Analysis of leakage in high pressure pipe using acoustic emission method, Appl. Acoust., 74 (2013) 335–342.

M. Mirzaei, Vibrational response of thin tubes to sequential moving pressures, Int. J. Mech. Sci., 59 (2012) 44–54.

A. M. Al-Ghamd and D. Mba, A comparative experimental study on the use of acoustic emission and vibration analysis for bearing defect identification and estimation of defect size, Mech. Syst. Signal Process., 20 (2006) 1537–1571.

Y. Lin and M. Sansalone, Transient response of thick circular and square bars subjected to transverse elastic impact, J. Acoust. Soc. Am., 91 (1992) 885–893.

F. Tong, X. M. Xu, B. L. Luk and K. P. Liu, Evaluation of tile-wall bonding integrity based on impact acoustics and support vector machine, Sensors Actuators A Phys., 144 (2008) 97–104.

R. Muldoon, A. Chalker, M. C. Forde, M. Ohtsu and F. Kunisue, Identifying voids in plastic ducts in post-tensioning prestressed concrete members by resonant frequency of impact-echo, SIBIE and tomography, Constr. Build. Mater., 21 (2007) 527–537.

T. B. Petersen, Acoustic emission from impacts of rigid bodies, J. Acoust. Emiss., 27 (2009) 98–113.

T. Kundu, S. Das and K. V Jata, Detection of the point of impact on a stiffened plate by the acoustic emission technique, Smart Mater. Struct., 18 (2009) 035006.

T. C. Pearson, A. E. Cetin, A. H. Tewfik and R. P. Haff, Feasibility of impact-acoustic emissions for detection of damaged wheat kernels, Digit. Signal Process., 17 (2007) 617–633.

J. J. da Silva, A. M. N. Lima, F. H. Neff and J. S. da Rocha Neto, Fouling detection based on vibration analysis with the hammer impact test, Proc. of IEEE Instrumentation & Measurement Technology Conference, Warsaw, Poland (2007) 1–5.

L. C. Lemos, J. M. R. Souza Neto, J. J. da Silva and J. S. da R. Neto, Fouling detection using hammer impact test and wireless comunication, Proc. Of IEEE Instrumentation and Measurement Technology Conference, Beijing, China (2011) 1–5.

G. C. McLaskey and S. D. Glaser, Acoustic emission sensor calibration for absolute source measurements, J. Nondestruct. Eval., 31 (2012) 157–168.

J. I. Ukpai, R. Barker, X. Hu and A. Neville, Exploring the erosive wear of X65 carbon steel by acoustic emission method, Wear, 301 (2013) 370–382.

G. Du, J. Li, W. K. Wang, C. Jiang and S. Z. Song, Detection and characterization of stress-corrosion cracking on 304 stainless steel by electrochemical noise and acoustic emission techniques, Corros. Sci., 53 (2011) 2918–2926.

B. L. Luk, K. P. Liu and F. Tong, Rapid evaluation of tilewall bonding integrity using multiple-head impact acoustic method, NDT E Int., 44 (2011) 297–304.

Y. He, X. Zhang and M. I. Friswell, Defect diagnosis for rolling element bearings using acoustic emission, J. Vib. Acoust., 131 (2009) 61012.

J. Lim and T. Kaewkongka, Leakage evaluation of heating coil tube in thermal oil boiler by using acoustic emission and data classification technique, Proc. of IEEE Instrum. Meas. Technol. Conf., Victoria, BC. (2008) 1659–1662.

T. P. Philippidis and T. T. Assimakopoulou, Using acoustic emission to assess shear strength degradation in FRP composites due to constant and variable amplitude fatigue loading, Compos. Sci. Technol., 68 (2008) 840–847.

B. Eftekharnejad, M. R. Carrasco, B. Charnley and D. Mba, The application of spectral kurtosis on Acoustic Emission and vibrations from a defective bearing, Mech. Syst. Signal Process., 25 (2011) 266–284.

S. Momon, M. Moevus, N. Godin, M. R’Mili, P. Reynaud, G. Fantozzi and G. Fayolle, Acoustic emission and lifetime prediction during static fatigue tests on ceramic-matrixcomposite at high temperature under air, Compos. Part A Appl. Sci. Manuf., 41 (2010) 913–918.

V. Kappatos and E. Dermatas, Feature selection for robust classification of crack and drop signals, Struct. Heal. Monit., 8 (2008) 59–70.

M. Mohammad, S. Abdullah, N. Jamaludin and M. Z. Nuawi, Correlating strain and acoustic emission signals of metallic component using global signal statistical approach, Adv. Mater. Res., 445 (2012) 1064–1069.

D. H. Pandya, S. H. Upadhyay and S. P. Harsha, Fault diagnosis of rolling element bearing with intrinsic mode function of acoustic emission data using APF-KNN, Expert Syst. Appl., 40 (2013) 4137–4145.

M. G. Droubi, R. L. Reuben and G. White, Statistical distribution models for monitoring acoustic emission (AE) energy of abrasive particle impacts on carbon steel, Mech. Syst. Signal Process., 30 (2012) 356–372.

M. Sansalone, Impact-echo: The complete story, ACI Struct. J., 94 (1997) 777–786.

M. Sansalone and W. B. Streett, Impact-Echo: Non-Destructive Evaluation of Concrete and Masonry, Bullbrier Press, New York (1997).

M. F. Shehadeh, Monitoring of long steel pipes using acoustic emission, Ph.D. Thesis, Heriot-Watt University (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Ohseop Song

A. H. Zakiah, M.S., studied mechanical engineering at the University of New South Wales, Australia in 2006. She started her career at Universiti Teknikal Malaysia Melaka (UTeM) as a lecturer in the field of materials testing. She is currently pursuing her Ph.D. study in Universiti Kebangsaan Malaysia (UKM). Her research interests are in the area of evaluation of defect behavior using non-destructive testing method such as Acoustic Emission for structural integrity assessment.

N. Jamaludin is an associate professor at Faculty of Engineering and Built Environment, Universiti Kebangsaan Malaysia (UKM). He earned his Ph.D. in 2000 in the area of condition monitoring at Cranfield University. He has more than 13 years of experience in the condition monitoring field. His research interests are investigations on material damage mechanism in structural and machinery components using Acoustic Emission and Metal Magnetic Memory Technology as part of integrity monitoring analysis and assessment. Assoc. Prof. Dr. Jamaludin is a fellow in Welding Institue of Malaysia, Chairman of Malaysian Acoustic Emission Working Group as well as member of Malaysian Society of Non Destructive Testing (MSNT).

J. Syarif earned his Ph.D. from Kyushu University, Japan in 2003. He is the receipient of Monbukagakusho Scholarship from 1998–2000 and 2000–2003 for his Master and Ph.D. degrees. After earning his Ph.D. he continued his career as a lecturer in Universiti Kebangsaan Malaysia (UKM) until promoted to his current position as an associate professor. He has more than 10 years experience in structural material engineering and properties, physical metalurgy as well as alloy design and has published approximately 70 papers in the respective field. Assoc. Prof. Dr. Syarif is a member of Iron and Steel Institute of Japan, Institute of Materials, Malaysia and Malaysian Powder Metallurgy and Particulate Materials Association.

S. Y. S. Yahya obtained his Ph.D. degree in advance materials from Universiti Kebangsaan Malaysia (UKM) in 2005. He is currently a senior lecturer at Faculty of Applied Science, Universiti Teknologi MARA and is teaching about Material Technology. His research expertise are in materials physics and advanced materials. Dr. Yahya is a member of Malaysia Society of Non Destructive Testing (MSNT) and American Society of Non Destructive Testing (ASNT).

Rights and permissions

About this article

Cite this article

Halim, Z.A., Jamaludin, N., Junaidi, S. et al. Vibration impact acoustic emission technique for identification and analysis of defects in carbon steel tubes: Part A Statistical analysis. J Mech Sci Technol 29, 1547–1557 (2015). https://doi.org/10.1007/s12206-015-0327-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-0327-3