Abstract

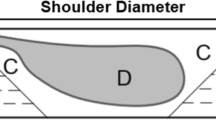

Friction stir welding (FSW) as an efficient solid state joining process has numerous applications in industries. Temperature distribution analysis through simulation not only brings the possibility to characterize the microstructure of different zones, but also enables one to save cost and energy as optimum welding variables are obtained with less concern. In the present study, the temperature distribution during the friction stir welding (FSW) process of AA6061-T6 was evaluated using finite element method (FEM). Since experimental measurements cannot be readily made in the weld region, it is difficult to understand physics in the stir zone of the welds without simulation. Abaqus software was applied to model the parts and simulate the process of welding, while Johnson-Cook law utilized to evaluate the effect of strain rate and generated heat. FE-results were verified by experimental results. The comparisons revealed a good compatibility between the results. The effect of probe shape on temperature distribution was also studied. It was found that spherical pins result in the highest temperatures at workpieces with respect to cylindrical and tapered pins. Additionally, it was concluded that more heat is generated in workpieces as pin angle increases.

Similar content being viewed by others

References

H. Ahmadi, N. B. M. Arab and F. A. Ghasemi, Optimization of process parameters for friction stir lap welding of carbon fibre reinforced thermoplastic composites by Taguchi method, J. Mech. Sci. Technol., 28 (2014) 279–284.

M. D. Giorgi, A. Scialpi, F. W. Panella and L. A. C. D. Filippis, Effect of shoulder geometry on residual stress and fatigue properties of AA6082 FSW joints, J. Mech. Sci. Technol., 23 (2009) 26–35.

K. Colligan, Material flow behaviour during friction stir welding of aluminum, First International Symposium on Friction Stir Welding, Thousand Oaks, CA, USA (1999) 14–16.

C. G. Rhodes, M. W. Mahoney, W. H. Bingel, R. A. Spurling and C. C. Bampton, Effects of friction stir welding of microstructure of 7075 aluminum, J. Scripta Mater, 36 (1997) 69–75.

T. Saeid, A. Abdollah-zadeh, H. Assadi and F. Malek Ghaini, Effect of friction stir welding speed on the microstructure and mechanical properties of a duplex stainless steel, J. Mater. Sci. Eng. (2008) 262–268.

Y. M. Hwang, P. L. Fan and C. H. Lin, Experimental study on Friction Stir Welding of copper metals, J. Mater. Process. Technol., 210 (2010) 1667–1672.

K. Elangovan, V. Balasubramanian and S. Babu, Predicting tensile strength of friction stir welded AA6061 aluminium alloy joints by a mathematical model, J. Mater. Des., 30 (2009) 188–193.

M. Assidi, L. Fourment, S. Guerdoux and T. Nelson. Friction model for friction stir welding process simulation: Calibration from welding experiment, Int. J. Mach. Manuf., 50 (2010) 143–155.

Z. Zhang, J. T. Chen, Z. W. Zhang and H. W. Zhang, Coupled thermo-mechanical model based comparison of friction stir welding processes of AA2024-T3 in different thicknesses, J. Mater. Sci., 46 (2011) 5815–5821.

J. Fish, C. Oskay, R. Fan and R. Barsoum, Al 6061- T6-Elastomer Impact Simulations, June 21 (2005).

M. Song and R. Kovacevic, Thermal modeling of fraction stir welding in a moving coordinate system and its validation, Int. J. Mach Manuf., 43 (2003) 605–615.

L. Li, D. Aidun and P. Marzocca, 3-D thermo-mechanical analysis of friction stir welding of dissimilar metals using functionally graded material concept, Trends in Welding Research 2008 (ASM International) (2009) 726–730.

R. Keivani, B. Bagherim, F. Sharifi, M. Ketabchi and M. Abbasi, Effects of pin angle and preheating on temperature distribution during friction stir welding process, Trans. Nonferrous Met. Soc. China, 23 (2013) 2708–2713.

R. S. Mishra and M. W. Mahoney, Friction stir welding and processing, ASM International, Materials Park, Ohio (2007).

W. J. Arbegast and P. J. Hartley, Friction stir weld technology development at Lockheed Martin Michoud space systems-An overview, Proceedings of the Fifth International Conference on Trends in Welding Research, Pine Mountain, GA, USA (1998) 541–554.

R. S. Mishra and Z. Y. Ma, Friction stir welding and processing, J. Mater. Sci. Eng., 50 (2005) 1–78.

W. M. Thomas and E. D. Nicholas, Friction stir welding for the transportation industries, J. Mater. Des., 18 (1997) 269–273.

W. F. Hosford and R. M. Caddell, Metal formingmechanics and metallurgy, 3rd ed., Cambridge University Press, Cambridge (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Yong-Tae Kim

Behrouz Bagheri graduated from Amirkabir University of Technology, Tehran, Iran in 2011. He took his master degree in Materials science and Engineering. Simulation of metal forming and welding processes are his main research fields of study.

Rights and permissions

About this article

Cite this article

Abbasi, M., Bagheri, B. & Keivani, R. Thermal analysis of friction stir welding process and investigation into affective parameters using simulation. J Mech Sci Technol 29, 861–866 (2015). https://doi.org/10.1007/s12206-015-0149-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-0149-3