Abstract

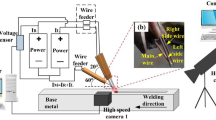

Short-arc pulsed gas metal arc welding (P-GMAW) was used to solve the difficulties of molten pool spreading and droplet transfer of Ni-based welding wire. Suppression of short-circuit current was used to reduce spatter. Arc length stabilizer was used to acquire a proper and stable arc length maintained at the critical position where short circuit starts to occur. Short-arc P-GMAW with or without arc length stabilizer was compared. The droplet transfer, arc behaviors and weld bead profiles were investigated and compared based on the high-speed photography and observation of weld cross-section. When the arc length stabilizer was deactivated, the arc length was unstable and too short. The droplet transfer mode was mainly short circuit partial transfer, with only a small part of the droplet transferred into the molten pool, with the characteristics of no obvious necking, a few spatters, small droplet impact, long short circuit duration and high short-circuit current. There was also a small proportion of short circuit complete transfer with obvious necking, larger droplet impact, shorter short-circuit duration and lower short-circuit current. With arc length stabilizer, droplet transfer modes were short circuit complete transfer and spray transfer. The spray transfer had the largest droplet impact, no short circuit and no spatter. With the arc length stabilizer activated, a deep penetration, a high penetration ratio, a small reinforcement and a large reinforcement factor were acquired. This provides an innovative method to solve the difficulties of droplet transfer and molten pool spreading and eliminate the incomplete fusion in the GMAW of 9%Ni steel with nickel-based alloy welding wire.

摘要

本文采用短电弧脉冲熔化极气体保护焊解决了镍基合金焊丝熔池铺展与熔滴过渡困难; 使用短路电流抑制以减少焊接飞溅; 采用弧长稳定器获取稳定的短电弧, 将电弧长度维持在短路出现的临界位置. 本文比较了弧长稳定器开启与关闭状态下的短电弧脉冲熔化极气体保护焊. 基于高速摄影与焊缝截面研究了焊接过程中的电弧行为、 熔滴过渡、 焊缝形态. 当电弧稳定器关闭时, 电弧长度过短且不稳定: 熔滴过渡形式主要为短路部分过渡, 仅有一小部分熔滴进入熔池, 熔滴没有明显缩颈, 存在焊接飞溅; 熔滴对熔池的冲击作用小, 短路时间长、 短路电流大. 电弧稳定器关闭情况下仅有小部分熔滴过渡形式为短路完全过渡, 熔滴过渡过程中存在明显缩颈, 熔滴对熔池冲击更大, 短路电流小、 短路持续时间短. 启用电弧长度稳定器, 熔滴过渡形式为短路完全过渡与射滴过渡. 射滴过渡对熔池的冲击力最大, 不存在短路与飞溅. 采用电弧长度稳定器, 可以获得更大的焊缝熔深与熔合比、 较小的余高与更大的余高因数. 这为解决9Ni钢镍基合金焊丝熔化极气体保护焊熔滴过渡与熔池铺展困难、 消除未熔合缺陷提供了一种新的思路.

Similar content being viewed by others

References

KIM S H, KANG C Y, BANG K S. Weld metal impact toughness of electron beam welded 9% Ni steel [J]. Journal of Materials Science, 2001, 36(5): 119–1200.

KHODIR S, SHIBAYANAGI T, TAKAHASHI M, et al. Microstructural evolution and mechanical properties of high strength 3–9% Ni-steel alloys weld metals produced by electron beam welding [J]. Materials & Design, 2014, 60: 391–400.

WU Y, CAI Y, SUN D W, et al. Microstructure and properties of high-power laser welding of SUS304 to SA553 for cryogenic applications [J]. Journal of Materials Processing Technology, 2015, 225: 56–66.

QU Z X, XIA L Q, WANG X J. The study on welding technology of 9Ni steel [J]. Materials Science Forum, 2018, 941: 516–523.

MU W D, LI Y Z, CAI Y, et al. Cryogenic fracture toughness of 9%Ni steel flux cored arc welds [J]. Journal of Materials Processing Technology, 2018, 252: 804–812.

KAR J, ROY S K, ROY G G. Influence of beam oscillation in electron beam welding of Ti-6AL-4V [J]. The International Journal of Advanced Manufacturing Technology, 2018, 94(9/10/11/12): 4531–4541.

LI R F, ZHANG F, SUN T Z, et al. Investigation of strengthening mechanism of commercially pure titanium joints fabricated by autogenously laser beam welding and laser-MIG hybrid welding processes [J]. The International Journal of Advanced Manufacturing Technology, 2019, 101(1/2/3/4): 377–389.

USHIO M, MATSUDA F. Effect of oxygen on stabilization of arc in 9%Ni-steel GMA welding [J]. Transactions of JWRI, 1978, 7(1): 93–100.

MATSUDA F, USHIO M, SAIKAWA S, et al. GMA welding of 9%Ni-steel with similarly composed nickel alloy wire in helium shielding [J]. Transactions of JWRI, 1981, 10(2): 153–161.

NAKAMURA T, HIRAOKA K. GMA welding of 9% Ni steel in pure argon shielding gas using coaxial multilayer solid wire [J]. Welding in the World, 2013, 57(6): 743–752.

MAHIN K W, MORRIS J W, WATANABE I. A review of the development of ferritic consumables for the welding of 9%-nickel steel: Research in the United States and Japan [M]//Advances in cryogenic engineering materials. Boston: Springer, 1980: 187–199.

EL-BATAHGY A M, GUMENYUK A, GOOK S, et al. Comparison between GTA and laser beam welding of 9%Ni steel for critical cryogenic applications [J]. Journal of Materials Processing Technology, 2018, 261: 193–201.

MO W L, LU S P, LI D Z, et al. Research and development of Ni-based filler wire for key components of nuclear power plant [J]. Transactions of the China Welding Institution, 2014, 35(6): 90–94, 117 (in Chinese).

SCOTTI A, PONOMAREV V, LUCAS W. A scientific application oriented classification for metal transfer modes in GMA welding [J]. Journal of Materials Processing Technology, 2012, 212(6): 1406–1413.

TSAI N S, EAGAR T W. Distribution of the heat and current fluxes in gas tungsten arcs [J]. Metallurgical Transactions B, 1985, 16(4): 841–846.

FAN H G, SHI Y W. Numerical simulation of the arc pressure in gas tungsten arc welding [J]. Journal of Materials Processing Technology, 1996, 61(3): 302–308.

PRAVEEN P, YARLAGADDA P K D V. Meeting challenges in welding of aluminum alloys through pulse gas metal arc welding [J]. Journal of Materials Processing Technology, 2005, 164/165: 1106–1112.

PALANI P K, MURUGAN N. Selection of parameters of pulsed current gas metal arc welding [J]. Journal of Materials Processing Technology, 2006, 172(1): 1–10.

PRAVEEN P, YARLAGADDA P K D V, KANG M J. Advancements in pulse gas metal arc welding [J]. Journal of Materials Processing Technology, 2005, 164/165: 1113–1119.

HERMANS M, OUDEN G. Process behavior and stability in short circuit gas metal arc welding [J]. Welding Journal, 1999, 78(4): 137–141.

LIN Q, LI X, SIMPSON S W. Metal transfer measurements in gas metal arc welding [J]. Journal of Physics D: Applied Physics, 2001, 34(3): 347–353.

CAO Z N, DONG P S. Modeling of GMA weld pools with consideration of droplet impact [J]. Journal of Engineering Materials and Technology, 1998, 120(4): 313–320.

MAMAT S B, TASHIRO S, TANAKA M, et al. Study on factors affecting the droplet temperature in plasma MIG welding process [J]. Journal of Physics D: Applied Physics, 2018, 51(13): 135206.

OGINO Y, HIRATA Y, MURPHY A B. Numerical simulation of GMAW process using Ar and an Ar—CO2gas mixture [J]. Welding in the World, 2016, 60(2): 345–353.

CAI X Y, LIN S B, MURPHY A B, et al. Influence of helium content on a ternary-gas-shielded GMAW process [J]. Welding in the World, 2018, 62(5): 973–984.

HERTEL M, ROSE S, FÜSSEL U. Numerical simulation of arc and droplet transfer in pulsed GMAW of mild steel in argon [J]. Welding in the World, 2016, 60(5): 1055–1061.

YAN Z Y, ZHAO Y, JIANG F, et al. Metal transfer behaviour of CMT-based step-over deposition in fabricating slant features [J]. Journal of Manufacturing Processes, 2021, 71: 147–155.

GAN Z T, LIAN Y P, LIN S E, et al. Benchmark study of thermal behavior, surface topography, and dendritic microstructure in selective laser melting of inconel 625 [J]. Integrating Materials and Manufacturing Innovation, 2019, 8(2): 178–193.

XU W H, DONG C L, ZHANG Y P, et al. Characteristics and mechanisms of weld formation during oscillating arc narrow gap vertical up GMA welding [J]. Welding in the World, 2017, 61(2): 241–248.

YANG C, LIN S. Arc welding base [M]. Harbin: Harbin Institute of Technology Press, 2003 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the MARK III Materials Research Project of Ministry of Industry and Information Technology of China

Rights and permissions

About this article

Cite this article

Liu, Y., Hua, X., Wu, D. et al. Arc and Droplet Behaviors in Horizontal Short-Arc Pulsed Gas Metal Arc Welding of 9%Ni Steel with ERNiCrMo-3 Welding Wire. J. Shanghai Jiaotong Univ. (Sci.) 29, 361–376 (2024). https://doi.org/10.1007/s12204-022-2548-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-022-2548-9

Key words

- droplet transfer

- arc behaviors

- weld bead formation

- short-arc pulsed gas metal arc welding (P-GMAW)

- high nickel alloy

- 9%Ni steel