Abstract

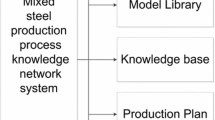

To increase efficiency in fierce competition, it is necessary and urgent to improve the standard of production planning for shipbuilding. The construction of curved blocks is the bottleneck to improve the efficiency of shipbuilding. Thus it is a key breakthrough for higher shipbuilding productivity to study the curved block production. By analyzing the scheduling problem in curved blocks production, we propose an intelligent curved block production scheduling method and its system based on a knowledge base, and show the main process of the system. The functions of the system include data management, assembly plan generation, plan adjustment, and plan evaluation. In order to deal with the actual situation and inherit the empirical knowledge, the system extracts some rules to control block selecting, algorithm selection, and evaluation thresholds to build a production decision-making knowledge base in the curved block scheduling system. The proposed knowledge base could be referred and modified by users, especially after a few interactions between the users and the knowledge base. The final assembly plan can be visualized and evaluated to facilitate the observation of plan implementation and effects of the decisions in the process. Finally, the system is verified by a large shipyard in Shanghai using real data and the results illustrate that the proposed method can perform the knowledge-based scheduling for curved blocks construction effectively.

Similar content being viewed by others

References

GARCÍA-CRESPO Á, RUIZ-MEZCUA B, LÓPEZ-CUADRADO J L, et al. A review of conventional and knowledge based systems for machining price quotation [J]. Journal of Intelligent Manufacturing, 2011, 22(6): 823–841.

JOHNSON L M, DILEEPAN P, SEN T P. Knowledge based scheduling systems: A framework [J]. Journal of Intelligent Manufacturing, 1990, 1(2): 117–123.

YIH Y. Trace-driven knowledge acquisition (TDKA) for rule-based real time scheduling systems [J]. Journal of Intelligent Manufacturing, 1990, 1(4): 217–229.

WANG X G, BAI Y W, CAI C L, et al. A production rule-based knowledge system for software quality evaluation [C]//2010 2nd International Conference on Computer Engineering and Technology. Chengdu: IEEE, 2010: V6–208–V6–211.

ZHANG H, ROY U. A semantics-based dispatching rule selection approach for job shop scheduling [J]. Journal of Intelligent Manufacturing, 2019, 30(7): 2759–2779.

SHI M Y. Knowledge graph question and answer system for mechanical intelligent manufacturing based on deep learning [J]. Mathematical Problems in Engineering, 2021, 2021: 1–8.

CHOI H, PARK K. Shop-floor scheduling at shipbuilding yards using the multiple intelligent agent system [J]. Journal of Intelligent Manufacturing, 1997, 8: 505–515.

HUR M, LEE S K, KIM B, et al. A study on the manhour prediction system for shipbuilding [J]. Journal of Intelligent Manufacturing, 2015, 26(6): 1267–1279.

CAO J Y, FAN S D, LU W. The research on rule-based method to automatic risk identification for shipbuilding inspection [C]//2017 4th International Conference on Transportation Information and Safety. Banff: IEEE, 2017: 1182–1188.

LEE K J, LEE J K, CHOI S Y. A spatial scheduling system and its application to shipbuilding: DASCURVE [J]. Expert Systems with Applications, 1996, 10(3/4): 311–324.

ZHANG Y J, CI H Y. Research on irregular block spatial scheduling algorithm in shipbuilding [M]//Advances in intelligent, interactive systems and applications. Cham: Springer, 2018: 1130–1136.

CHO K K, CHUNG K H, PARK C, et al. A spatial scheduling system for block painting process in shipbuilding [J]. CIRP Annals, 2001, 50(1): 339–342.

ZHUO L, DAVID K H C, KENG H W, et al. A simulation model for spatial scheduling of dynamic block assembly in shipbuilding [J]//Journal of Engineering, Project, and Production Management, 2011, 1(1): 3–12.

TAO N R, JIANG Z H, ZHEN L. Spatial scheduling and workforce assignment problem in block assembly shop of shipbuilding [J]. Asia-Pacific Journal of Operational Research, 2014, 31(1): 1450006.

KWON B, LEE G M. Spatial scheduling for large assembly blocks in shipbuilding [J]. Computers & Industrial Engineering, 2015, 89: 203–212.

SHANG Z Y, GU J N, DING W, et al. Spatial scheduling optimization algorithm for block assembly in shipbuilding [J]. Mathematical Problems in Engineering, 2017, 2017: 1923646.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the China High-Tech Ship Project of the Ministry of Industry and Information Technology (No. 2021-51 (MC-202032-Z08))

Rights and permissions

About this article

Cite this article

Jiang, Z., Zhou, H., Tao, N. et al. Knowledge-Based Curved Block Construction Scheduling and Application in Shipbuilding. J. Shanghai Jiaotong Univ. (Sci.) (2022). https://doi.org/10.1007/s12204-022-2544-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12204-022-2544-0