Abstract

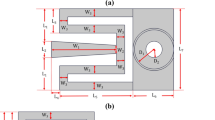

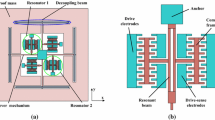

This study proposes a novel design and micromachining process for a dual-cantilever accelerometer. Comb and curved-surface structures are integrated into the sensing structure to modulate the squeeze-film damping, thus effectively optimizing the response frequency bandwidth. Owing to the high stress concentration on the dual-cantilever integrated with a fully sensitive piezoresistive Wheatstone bridge, a high sensitivity to acceleration is achieved. In addition, the dual-cantilever accelerometer is fabricated using a specifically developed low-cost and high-yield (111)-silicon single-side bulk-micromachining process. The test results show that the proposed dual-cantilever accelerometer exhibits a sensitivity of 0.086–0.088 mV/g/3.3 V and a nonlinearity of ±(0.09%–0.23%) FS (full-scale). Based on dynamic characterization, an adequate frequency bandwidth of 2.64 kHz is verified. Furthermore, a resonant frequency of 4.388 kHz is measured, and a low quality factor (Q) of 7.62 is obtained, which agrees well with the design for air-damping modulation. The achieved high performance renders the proposed dual-cantilever accelerometer promising in applications such as automotive and consumer electronics.

摘要

本研究提出了一种新型双悬臂加速度计的设计和微加工工艺技术。传感结构中集成有梳齿和空气微间隙结构,以调节压膜空气阻尼效应,进而有效地优化了传感器的频率响应和带宽特性。由于压阻惠斯通全桥集成在双悬臂梁上实现了高效率的应力集中,实现了对加速度检测的高灵敏度。此外,双悬臂加速度计采用了具有低成本和高成品率的(111)硅单面体微加工工艺来实现制造。传感器测试结果表明,所提出的双悬臂加速度计的灵敏度为0.086~0.088 mV/g/3.3V,全量程的非线性为±(0.09%~0.23%)。动态特性表征结果显示了2.64 kHz的充足频率带宽。传感器具有4.388 kHz谐振频率,并将品质因子(Q值)控制在7.62,与空气阻尼调制效应的设计结果高度一致。该双悬臂加速度计实现了较高的性能,在汽车和消费电子等领域具有很好的应用前景。

Similar content being viewed by others

References

NARASIMHAN V, LI H, JIANMIN M. Micromachined high-g accelerometers: A review [J]. Journal of Micromechanics and Microengineering, 2015, 25(3): 033001.

RUZZA G, GUERRIERO L, REVELLINO P, et al. Thermal compensation of low-cost MEMS accelerometers for tilt measurements [J]. Sensors, 2018, 18(8): 2536.

HAN J, ZHAO Z, NIU W, et al. A low cross-axis sensitivity piezoresistive accelerometer fabricated by masked-maskless wet etching [J]. Sensors and Actuators A: Physical, 2018, 283: 17–25.

DONG J, LONG Z, JIANG H, et al. Monolithic-integrated piezoresistive MEMS accelerometer pressure sensor with glass-silicon-glass sandwich structure [J]. Microsystem Technologies, 2017, 23(5): 1563–1574.

XIAO D B, LI Q S, HOU Z Q, et al. A novel sandwich differential capacitive accelerometer with symmetrical double-sided serpentine beam-mass structure [J]. Journal of Micromechanics and Microengineering, 2016, 26(2): 025005.

CHAE J, KULAH H, NAJAFI K. A CMOS-compatible high aspect ratio silicon-on-glass in-plane micro-accelerometer [J]. Journal of Micromechanics and Microengineering, 2005, 15(2): 336–345.

FAN K, CHE L, XIONG B, et al. A silicon micromachined high-shock accelerometer with a bonded hinge structure [J]. Journal of Micromechanics and Microengineering, 2007, 17(6): 1206.

SABATO A, NIEZRECKI C, FORTINO G. Wireless MEMS-based accelerometer sensor boards for structural vibration monitoring: A review [J]. IEEE Sensors Journal, 2017, 17(2): 226–235.

SHEN S, CHEN J, BAO M. Analysis on twin-mass structure for a piezoresistive accelerometer [J]. Sensors and Actuators A: Physical, 1992, 34(2): 101–107.

CRESCINI D, MARIOLI D, TARONI A. Low-cost accelerometers: Two examples in thick-film technology [J]. Sensors and Actuators A: Physical, 1996, 55(2/3): 79–85.

DONG J, LI X, WANG Y, et al. Silicon micromachined high-shock accelerometers with a curved-surface-application structure for over-range stop protection and free-mode-resonance depression [J]. Journal of Micromechanics and Microengineering, 2002, 12(6): 742–746.

MO Y, DU L, QU B, et al. Squeeze film air damping ratio analysis of a silicon capacitive micromechanical accelerometer [J]. Microsystem Technologies, 2018, 24(2): 1089–1095.

KAVITHA C, MADHAN M G. Study of squeeze film damping characteristics under different gas mediums in a capacitive MEMS accelerometer [J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2016, 38(1): 241–252.

BAO M. Chapter 3: Air damping [M]//Micro mechanical transducers-pressure sensors, accelerometers and gyroscopes. Amsterdam: Elsevier, 2000: 89–137.

HSIEH H S, CHANG H C, HU C F, et al. Method for performance improvement and size shrinkage of a three-axis piezoresistive accelerometer with guard-ring structure [C]//SENSORS, 2012 IEEE. Taipei: IEEE, 2012: 1–4.

ROY A L, SARKAR H, DUTTA A, et al. A high precision SOI MEMS-CMOS ±4g piezoresistive accelerometer [J]. Sensors and Actuators A: Physical, 2014, 210: 77–85.

WEI C, ZHOU W, WANG Q, et al. TPMS (tire-pressure monitoring system) sensors: Monolithic integration of surface-micromachined piezoresistive pressure sensor and self-testable accelerometer [J]. Microelectronic Engineering, 2012, 91: 167–173.

Acknowledgement

The authors wish to thank the Microsystem Technology Processing Service Platform for providing micromachining processes.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

the National Key R&D Program of China (Nos. 2016YFA0200800 and 2016YFA0200803), and the National Natural Science Foundation of China (Nos. 61674160 and 61834007)

Rights and permissions

About this article

Cite this article

Jiao, D., Ni, Z., Wang, J. et al. High-Performance Single-Side Fabricated (111)-Silicon Dual-Cantilever Accelerometer with Squeeze-Film Air Damping Modulation. J. Shanghai Jiaotong Univ. (Sci.) 28, 197–206 (2023). https://doi.org/10.1007/s12204-021-2288-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-021-2288-2