Abstract

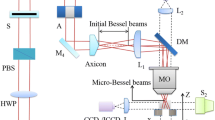

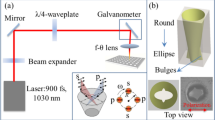

A near-infrared femtosecond laser is focused by a 100 mm-focal-length plano-convex lens to form a laser filament, which is employed to drill holes on copper targets. By shifting or rotating the focusing lens, additional aberration is imposed on the focused laser beam, and significant influence is produced on the aspect ratio and cross-sectional shape of the micro-holes. Experimental results show that when proper aberration is introduced, the copper plate with a thickness of 3 mm can be drilled through with an aspect ratio of 30, while no through-holes can be drilled on 3-mm-thickness copper plates by femtosecond laser with minimized aberration. In addition, when femtosecond laser filament with large astigmatism is used, micro-holes that had a length to width ratio up to 3.3 on the cross-section are obtained. Therefore, the method proposed here can be used to fabricate long oval holes with high aspect ratios.

Similar content being viewed by others

References

Prakash V, Kumar P, Singh P, Hussain M, Das A, Chattopadhyaya S. Micro-electrical discharge machining of difficult-to-machine materials: a review. Proceedings of the Institution of Mechanical Engineers. Part B, Journal of Engineering Manufacture, 2019, 233 (2): 339–370

Zeng Z, Wang Y, Wang Z, Shan D, He X. A study of micro-EDM and micro-ECM combined milling for 3D metallic micro-structures. Precision Engineering, 2012, 36(3): 500–509

Schaaf P. Laser Processing of Materials: Fundamentals, Applications and Developments. New York: Springer, 2010

Zhang H, Di J, Zhou M, Yan Y. A comparison in laser precision drilling of stainless steel 304 with nanosecond and picosecond laser pulses. Chinese Journal of Mechanical Engineering, 2014, 27(5): 972–977

Kling R, Dijoux M, Romoli L, Tantussi F, Sanabria J, Mottay E. Metal microdrilling combining high power femtosecond laser and trepanning head. In: Proceedings of Laser-based Micro- and Nanopackaging and Assembly VII. San Francisco: SPIE, 2013, 86080F

Jiang S, Hu Y, Wu H, Zhang Y, Zhang Y, Wang Y, Zhang Y, Zhu W, Li J, Wu D, Chu J. Multifunctional janus microplates arrays actuated by magnetic fields for water/light switches and bio-inspired assimilatory coloration. Advanced Materials, 2019, 31(15): e1807507

Zhu S, Bian Y, Wu T, Chen C, Jiao Y, Jiang Z, Huang Z, Li E, Li J, Chu J, Hu Y, Wu D, Jiang L. High performance bubble manipulation on ferrofluid-infused laser-ablated microstructured surfaces. Nano Letters, 2020, 20(7): 5513–5521

Braun A, Korn G, Liu X, Du D, Squier J, Mourou G. Self-channeling of high-peak-power femtosecond laser pulses in air. Optics Letters, 1995, 20(1): 73–75

Kasparian J, Sauerbrey R, Chin S. The critical laser intensity of self-guided light filaments in air. Applied Physics. B, Lasers and Optics, 2000, 71(6): 877–879

Xu Z J, Liu W, Zhang N, Wang M W, Zhu X N. Effect of intensity clamping on laser ablation by intense femtosecond laser pulses. Optics Express, 2008, 16(6): 3604–3609

Schwarz J, Diels J C. UV filaments and their application for laser-induced lightning and high-aspect-ratio hole drilling. Applied Physics. A, Materials Science & Processing, 2003, 77(2): 185–191

Kiselev D, Woeste L, Wolf J P. Filament-induced laser machining (FILM). Applied Physics. B, Lasers and Optics, 2010, 100(3): 515–520

Wang Z, Jiang L, Li X, Wang A, Yao Z, Zhang K, Lu Y. High-throughput microchannel fabrication in fused silica by temporally shaped femtosecond laser Bessel-beam-assisted chemical etching. Optics Letters, 2018, 43(1): 98–101

He F, Yu J, Tan Y, Chu W, Zhou C, Cheng Y, Sugioka K. Tailoring femtosecond 1.5-µm Bessel beams for manufacturing high-aspect-ratio through-silicon vias. Scientific Reports, 2017, 7(1): 40785

Pan D, Xu B, Liu S, Li J, Hu Y, Wu D, Chu J. Amplitude-phase optimized long depth of focus femtosecond axilens beam for single-exposure fabrication of high-aspect-ratio microstructures. Optics Letters, 2020, 45(9): 2584–2587

Leigh S, Sezer K, Li L, Grafton-Reed C, Cuttell M. Recast and oxide formation in laser-drilled acute holes in CMSX-4 nickel single-crystal superalloy. Proceedings of the Institution of Mechanical Engineers. Part B, Journal of Engineering Manufacture, 2010, 224 (7): 1005–1016

Zheng C, Zhao K, Shen H, Zhao X, Yao Z. Crack behavior in ultrafast laser drilling of thermal barrier coated nickel superalloy. Journal of Materials Processing Technology, 2020, 282: 116678

Méchain G, Couairon A, Franco M, Prade B, Mysyrowicz A. Organizing multiple femtosecond filaments in air. Physical Review Letters, 2004, 93(3): 035003

Fu Y, Gao H, Chu W, Ni J, Xiong H, Xu H, Yao J, Zeng B, Liu W, Cheng Y, Xu Z, Chin S L. Control of filament branching in air by astigmatically focused femtosecond laser pulses. Applied Physics B, Lasers and Optics, 2011, 103(2): 435–439

Eisenmann S, Pukhov A, Zigler A. Fine structure of a laser-plasma filament in air. Physical Review Letters, 2007, 98(15): 155002

Kamali Y, Sun Q, Daigle J F, Azarm A, Bernhardt J, Chin S L J O C. Lens tilting effect on filamentation and filament-induced fluorescence. Optics Communications, 2009, 282(5): 950–954

Goodwin P C. Evaluating optical aberrations using fluorescent microspheres: methods, analysis, and corrective actions. Methods in Cell Biology, 2013, 114: 369–385

Das D K, Pollock T M. Femtosecond laser machining of cooling holes in thermal barrier coated CMSX4 superalloy. Journal of Materials Processing Technology, 2009, 209(15–16): 5661–5668

Uchtmann H, He C, Gillner A. High precision and high aspect ratio laser drilling: challenges and solutions. In: Proceedings of Conference on High-Power Laser Materials Processing-Lasers, Beam Delivery, Diagnostics, and Applications V. San Francisco: SPIE, 2016

Mincuzzi G, Faucon M, Kling R. Novel approaches in zero taper, fast drilling of thick metallic parts by ultra-short pulse laser. Optics and Lasers in Engineering, 2019, 118: 52–57

Acknowledgements

This work was supported by the National Key Research and Development Program (No. 2018YFB0504400).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manshi Wang received her B.S. degree in Physics from Nanjing Normal University, China, in 2019. From 2019 until now, she is pursing a master’s degree in Optical Engineering at Institute of Modern Optics, Nankai University, China. Her research focuses on ultrafast laser processing and laser-induced periodic surface structures.

Zhiqiang Yu received his Bachelor’s degree in Optoelectronic Information Science and Engineering from School of Optoelectronic Engineering, Changchun University of Science and Technology, China, in 2017. From September 2017 to June 2019, he received his M.S. degree in Optical Engineering from Institute of Modern Optics, School of Electronic Information Science and Engineering, Nankai University, China. From September 2019 to the present, he is pursuing a Ph.D. degree in Optical Engineering at Institute of Modern Optics, School of Electronic Information Science and Engineering, Nankai University. Currently, he engages in research on ultrafast optics and its applications.

Nan Zhang receive his Ph.D. degree in Optical Engineering from Nankai University, China, in 2009. From 2009 to 2013, he was a lecturer in Nankai University; from 2013 to present, he is an associate professor in Institute of Modern Optics, Nankai University. His major research field is ultrafast laser-matter interaction, including the ultrafast thermodynamic evolution of femtosecond laser ablation, femtosecond laser induced periodic surface structures, and etc.

Weiwei Liu received his Ph.D. degree in Physics from Laval University, Québec, QC, Canada, in 2005. Since 2007, he has been working as a full professor with Institute of Modern Optics, Nankai University, China. His main research interests include ultrafast laser optics, THz science and technology, and nonlinear optics.

Rights and permissions

About this article

Cite this article

Wang, M., Yu, Z., Zhang, N. et al. Drilling high aspect ratio holes by femtosecond laser filament with aberrations. Front. Optoelectron. 14, 522–528 (2021). https://doi.org/10.1007/s12200-021-1214-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12200-021-1214-4