Abstract

Streamline-adjustment-assisted heterogeneous combination flooding is a new technology for enhanced oil recovery for post-polymer-flooded reservoirs. In this work, we first carried out a series of 2D visualization experiments for different chemical flooding scenarios after polymer flooding. Then, we explored the synergistic mechanisms of streamline-adjustment-assisted heterogeneous combination flooding for enhanced oil recovery and the contribution of each component. Test results show that for single heterogeneous combination flooding, the residual oil in the main streamline area after polymer flooding is ready to be driven, but it is difficult to be recovered in the non-main streamline area. Due to the effect of drainage and synergism, the streamline-adjustment-assisted heterogeneous combination flooding diverts the injected chemical agent from the main streamline area to the non-main streamline area, which consequently expands the active area of chemical flooding. Based on the results from the single-factor contribution of the quantitative analysis, the contribution of temporary plugging and profile control of branched preformed particle gels ranks in the first place and followed by the polymer profile control and the effect of streamline adjustment. On the contrary, the surfactant contributes the least to enhance the efficiency of oil displacement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Polymer flooding is an important enhanced oil recovery (EOR) method (Renouf 2014). China’s oil reserves are some 1.5 billion tonnes. There is still 40%–50% of the crude oil left in the formation after polymer flooding (Chang et al. 2006; Hou et al. 2009; Maghzi et al. 2014). Moreover, the remaining oil is much dispersed and is difficult to exploit (Hou 2007; Muhammed et al. 2012; Urbissinova et al. 2010; Zhang et al. 2014; Zhou et al. 2013). Therefore, researchers and engineers have developed many post-polymer-flooding EOR methods (Al-Ibadi and Civan 2013; Choi et al. 2010; Han et al. 2014; Lin et al. 2003; Pirayesh et al. 2014; Ranganathan et al. 1998; Sang et al. 2014; You et al. 2011; Wang et al. 2003; Wever et al. 2013), including alkali–surfactant–polymer (ASP) flooding, weak gel flooding and colloidal dispersion gel or bulk gel flooding. These EOR methods have been successfully implemented, but further applications are limited due to the complex geological properties and high risk of destructive blockage.

Cui et al. (2011) in Shengli Oilfield designed a novel suspended chemical flooding system according to the interaction of chemical agents. The suspended chemical, which is a heterogeneous combination flooding system, was developed for further enhancing oil recovery of reservoirs under more harsh and complicated conditions after polymer flooding. The suspended system consisted of the branched preformed particle gels (B-PPG) (Coste et al. 2000; Goudarzi et al. 2014) and a homogeneous solution contained polymer and surfactant. So it has heterogeneous characteristics due to the coexistence of solid and fluid. Owing to the viscoelastic properties of B-PPG, the suspended particles can deform and pass the pore throats, which were able to control the dynamic profile effectively (Bai et al. 2007; Elsharafi and Bai 2012; Shi et al. 2011). In addition, the suspended system could also lead to a lower interface tension in the presence of surfactant. Consequently, the suspended system achieved high sweep efficiency and displacement efficiency. Core flooding tests proved that the heterogeneous combination flooding system could improve oil recovery significantly after polymer flooding.

Streamline adjustment methods play an important role in the streamline-adjustment-assisted heterogeneous combination flooding. One of the streamline adjustment methods is well-pattern infill and transformation. A pilot test of this new hybrid strategy has been carried out in the Zhongyi part of the Gudao reservoir, and it has achieved remarkable development performance. Its reservoir parameters are representative of post-polymer-flooding reservoirs. The initial well spacing is 270 m, and the row spacing is 300 m. After the well pattern was adjusted by well infilling, the well spacing is 135 m, and the row spacing is 150 m. The field trial included two injection slugs. The first slug is a 0.05-PV pre-protection slug, 1500 mg/L B-PPG + 1500 mg/L polymer solution. The second slug is the main slug of 0.3 PV solution consisting of 1200 mg/L B-PPG, 1200 mg/L polymer solution, 0.2% anionic surfactant and 0.2% nonionic surfactant. The pilot field trial has shown that it improves the oil recovery effectively. The injection pressure increased from 7.0 to 10.1 MPa. The resistance factor of the pilot field trial reached 2.20. The flow resistance increased significantly. Also, a significant water-cut reduction and oil-production enhancement were achieved. The water-cut curve of the pilot test decreased from 97.5% to 76.9%. The incremental oil recovery was estimated to be 8.5%, and the final recovery could reach 63.6% OOIP.

However, the EOR mechanisms of this hybrid strategy are very complex, since it involves the synergistic effect between chemical agents, the complex interactions between the continuous fluid phase and the dispersed particle phase and well-pattern adjustment.

Researchers have conducted extensive studies of the use of hybrid technologies for enhanced oil recovery. For example, Wang et al. (2009) analyzed the applications of surfactant–polymer (SP) flooding in the Shengli Oilfield and proposed that the synergistic effect of surfactant and polymer is the key to good development performance. Hou et al. (2013) studied the distribution characteristics of additional extracted oil displaced by SP flooding and analyzed the respective EOR mechanisms of surfactant, polymer and synthetic effects. Muhammed et al. (2012) studied the interaction between super-absorbent polymer gel and surfactants by physical experiments. He also proved that PPG treatment is a cost-effective profile control method. Chemical methods mainly improve the sweep efficiency and displacement efficiency in main streamline area between the injectors and producers. Well-pattern adjustment (Cipolla and Kyte 1992; Gould and Sarem 1989; Wu et al. 1989) can further enhance the development performance of the non-main streamline area because the streamlines can be totally changed. According to the studies by Flores et al. (2006), Sayyafzadeh et al. (2010) and Rose et al. (2011), well-pattern adjustment can induce the injected fluid to take effect in non-main streamline areas and further enlarge the sweeping area.

Though there are many studies concerning the synergistic effect of polymer and surfactant, the EOR mechanism of streamline adjustment is still unclear. There are a few studies conducted on the driving remaining oil mechanism of B-PPG, polymer, surfactant and streamline adjustment in heterogeneous combination flooding after polymer flooding. Studies of the synergistic mechanism between each chemical and streamline adjustment technology are still limited, which hinders the application of the hybrid strategy in more post-polymer-flooding reservoirs. Therefore, this work conducts experiments reflecting the injection–production relationships based on small-scale models. And more importantly, the streamline can be changed during the displacement process, so the experiments can reflect the effect of streamline adjustment. On this basis, we investigate the EOR mechanisms of the hybrid strategy and quantitatively analyze the relative contributions of B-PPG, polymer, surfactant and streamline adjustment in the hybrid strategy.

2 Experimental section

2.1 2D visualization experimental equipment

As shown in Fig. 1, the 2D visual physical equipment is composed of a fluid drive system (syringe pump), a 2D transparent sand-pack model, an effluent fluid separation and metering device, a HD macro- and micro-integrated zoom camera with large zoom ratio, a LED light source, a computer control and acquisition system and a spectral analysis of saturation system. Through the image and data acquisition system, computers can record the dynamic experimental process.

Figure 2 shows the top view of a 2D sand-pack model, which includes three injection wells, three production wells, six wellhead switches, a cruciform joint, a high transmittance plate and a sand-pack model. The cruciform joint connects the syringe pump, sand-pack model and the effluent fluid separation and metering device. Different fluids can be injected through the conversion of wellhead switches without interrupting the experiment. The sand-pack model consists of two pieces of transparent plate filled with sand. The transparent plates, with a size of \(2 0 0. 0\;{\text{mm}} \times 150. 0\;{\text{mm}} \times 4.0\;{\text{mm}}\), were bonded together with epoxy resin (a sealant), and the size of the sand-pack space was \(1 7 4. 0\;{\text{mm}} \times 120. 0\;{\text{mm}} \times 2.0\;{\text{mm}}\). The specially designed 2D physical model can simulate the effect of an infilling well pattern on the displacement oil by turning on (or off) the wellhead switches. There were six boreholes distributed uniformly in the sand-pack model, which were used to simulate injection wells and production wells. One injection well and one production well were open at the initial state. After the well-pattern infilling, three injection wells and three production wells were open. The well pattern changed from staggered well pattern to regular rectangular well pattern. The wells were perforated and covered with metal screens to guard against any flow of sand. The distance between wells of the same type was fixed at 86.0 mm, and the distance between the line of injection wells and production wells was set as 116.0 mm.

Top view of 2D sand-pack model. The blue solid circle with arrow line refers to the injection well in the open state, and the blue hollow circle with arrow line represents the closed state. The pink solid circle refers to the production well in the open state, and the pink hollow circle is in the closed state

2.2 Sand-pack model

In the experiments, quartz sand supplied by Shengli Oilfield was used. The size of 80% of the sand ranged from 45 to 50 mesh. In order to ensure the same wettability, fresh sand was packed at 20 °C in every test. The air permeability of the sand-pack models was 1.5–2.5 μm2. Brine water with a NaCl concentration of 2.5 wt% was injected to saturate sand-pack models to calculate their porosity. The porosity of the sand-pack models was about 35.0%–37.0%. The sand-pack models were saturated with brine, and this was then followed by injecting oil through three injection wells and three production wells to set up the initial oil saturations of sand-pack models. The whole oil saturation process of each experiment was recorded by the HD camera to ensure that all the sand-pack models had a uniform oil distribution in the initial state.

2.3 Experimental materials

A degassed crude oil was used for all the displacement experiments. The viscosity and density of this crude oil were 70 mPa·s and 0.8 g/cm3 at 20 °C, respectively. NaCl solution with a concentration of 2.5 wt% was used as injection water; such brine was also used to prepare all solutions in this study.

Polyacrylamide used in this work had an average molecular weight of 15 MDa. The viscosity of this polymer solution was 12.4 mPa·s at 1500 mg/L and 10.3 mPa·s at 1200 mg/L. The surfactant was sodium dodecyl benzene sulfonate (SDBS). B-PPG particles were provided by the Shengli Oilfield, China. The properties of these chemical agents are summarized in Table 1.

2.4 Experimental procedures

All experiments were conducted at 20 °C. The rate of water flooding, chemical flooding and the following water flooding were fixed at 0.60, 0.35 and 0.60 mL/min, respectively. The detailed steps are as follows: (1) connect the experimental device as shown in Fig. 1 and open the camera; (2) saturate the sand-pack model with brine after vacuum pumping, then displace the brine with crude oil, and finally stop the displacement after reaching the irreducible water saturation; (3) water flooding: start the displacement with brine at a rate of 0.60 mL/min until the water cut at the outlet reached 90% in the initial well pattern; (4) polymer flooding: inject the polymer solution into the model with a slug of 0.4 PV, a concentration of 1800 mg/L at an injection rate of 0.35 mL/min; (5) post-polymer water flooding: inject brine at a rate of 0.60 mL/min and stop when the water cut at the outlet reached 98%; (6) displacement using different development strategies: change the initial well pattern to regular rectangular well pattern by converting wellhead switches when the streamline adjustment technology was included; inject the chemical slug into the model at an injection rate of 0.35 mL/min when the chemical technology was included; (7) post-chemical water flooding; inject brine at an injection rate of 0.60 mL/min and stop when the water cut at the outlet reached 98%; (8) analyze the oil recovery percent at different displacement stages; (9) image treatment; capture images from the recorded video and analyze the effect at different displacement stages.

2.5 Scheme design

Table 2 presents the seven experimental schemes designed in this study. The first three schemes were used for combination strategy investigations, while the remaining schemes were used for single strategy investigation in streamline adjustment.

3 Results and discussion

3.1 Conversion of residual oil saturation

Different experiments have different remaining oil saturation due to the non-reproducibility of physical models. To reduce the influence of the remaining oil saturation difference, it is necessary to adjust the remaining oil saturation of different experiments to the same level. The “conversion factor” Z is used to convert the oil saturation of different experiments to the same level. The “conversion factor” Zn of the nth experiment is defined as the ratio of remaining oil saturation of the nth to the first experiment at the end of the water flooding after polymer flooding. The conversion value of residual oil saturation is expressed as follows.

where Son and So1 represent the residual oil saturation of the nth experiment and the first experiment, respectively; So represents the residual oil saturation at different stages of any experiment; \(S_{\text{o}}^{'}\) represents the conversion value of the residual oil saturation.

The cumulative recovery percent is the ratio of the cumulative volume of the produced oil to the volume of the initial saturated oil. The process recovery percent is the ratio of the volume of the produced oil to the volume of the initial saturated oil. The residual oil saturation, the conversion value, and the oil recovery percent (R, %) of the seven experiments are shown in Table 3. We can observe that the saturation of the initial oil for each experiment is close, but it is quite different at the subsequent water flooding stage of polymer flooding, and the minimum value is 48.9%, the maximum value is 57.2%. After the conversion according to Eq. (2), the oil saturation is 55.8%. The oil recovery of streamline-adjustment-assisted heterogeneous combination flooding is highest, reaching 76.3%. Next comes the recovery of heterogeneous combination flooding with 67.3%, but the main effect is on the subsequent water flooding stage. Experiments 4–7 show the effect of single chemical agent in the composite system.

3.2 Mechanisms of the hybrid strategy for enhanced oil recovery

3.2.1 Remaining oil distribution after polymer flooding

Experiment 1 reflected the polymer flooding development process, which included a water flooding stage and a polymer flooding stage. The remaining oil distribution at the end of water flooding and polymer flooding is shown in Fig. 3. From Fig. 3a, it can be seen that a large quantity of oil still remained after water flooding. There was a main streamline area (near the channel of water channeling) with a poorer oil accumulation and non-main streamline area (away from the channel of water channeling) with a richer oil accumulation between the injection and production wells. During the early period of water flooding, the injection water displaced oil to the production well in a fingering manner, since the viscosity of oil is higher than that of water. When the water front reached the production well, a main streamline would form between the injection and production wells. The remaining oil distributed discontinuously as an isolated island state due to the viscous fingering and high oil–water interfacial tension. In the non-main streamline area, the remaining oil distributed as a continuous state. This is because the viscosity of oil is higher than that of water and the oil in non-main streamline area cannot be readily driven by the injected water.

Polymer flooding has been proven to be an effective EOR method for high water-cut reservoirs. The viscosity of the polymer solution in reservoir conditions is higher than that of the injection water, which contributes to the increase in the sweep efficiency of the injected fluid. As shown in Fig. 3b, the main streamline area increased obviously, while the non-main streamline area decreased after polymer flooding with some oil driven out. Increasing the injected fluid viscosity is one aspect of the polymer flooding mechanisms, and another is the diversion caused by the formation of residual resistance. Compared with water flooding, the area of remaining oil as the continuous state decreased after polymer flooding, and some amount of remaining oil as the continuous state around the production well changed to the isolated island state. Several new thief channels emerged, and oil distribution became more complex.

3.2.2 Restart mechanisms of recovering remaining oil after polymer flooding

Figure 4 shows the distributions of residual oil at different stages in experiment 2. From Fig. 4a, it can be seen that the distribution of the remaining oil in the plane was more complex after polymer flooding. Polymer flooding extended the sweep range near the injection well. However, because the blocking effect of the polymer was weak, a significant channel was still formed between the injection and production wells, and a large amount of isolated island oil was formed.

Images of remaining oil distribution during heterogeneous combination flooding. a After polymer flooding. b Heterogeneous combination flooding, pre-slug 0.05 PV. c Heterogeneous combination flooding, main slug 0.15 PV. d Heterogeneous combination flooding, main slug 0.3 PV. e Followed by water flooding. f After heterogeneous combination flooding

The residual oil distribution in pre-slug, main slug and the subsequent water flooding stages is shown in Fig. 4b–f. The pre-slug was composed of highly concentrated B-PPG particles and polymer solution. From Fig. 4b, during the process of injection, the pre-slug mainly flowed along thief channels formed during polymer flooding. The pre-slug had good effect in plugging the thief channels due to its high particle concentration.

The main slug solution was composed of B-PPG particles, polymer and surfactant. As shown in Fig. 4c, fluid diversion occurred during the process of injection and another two streamlines took shape. The injected fluid moved divergently, and the displacement front was more balanced. Besides, the surfactant agent reduced the interfacial tension of the oil–water system to 0.0037 mN/m, resulting in little oil remaining around the injection well. From Fig. 4d, the injected solution diverted again to the channeling at the end of the main slug injection. Compared with Fig. 4a, the sweep area enlarged and indicated that B-PPG particles had flowed into the deep positions of the physical model. The polymer agent increased the solution viscosity and enhanced the carrying ability, making B-PPG particles flow through the porous media more easily. Surfactant in the polymer solution plays a skidding role during the transport of B-PPG particles. Polymer and surfactant in the suspended chemical solution help B-PPG transport in the porous media. That is to say, the polymer and surfactant assist B-PPG particles to fulfill deep profile control. During the heterogeneous combination flooding, chemical agents work together and change the distribution of remaining oil from the isolated island state to the continuous state, displacing oil into the production well.

The effect of in-depth fluid diversion became more significant during the following water flooding stage (see Fig. 4e–f). Heterogeneous combination flooding had greatly improved the sweep efficiency around the injection wells. The injection water was divided into several branches in the middle of the physical model, which resulted in several flow channels taking shape near the production well where the remaining oil was rich. Only a small amount of isolated island state remaining oil was located around the production well in the main streamline area.

3.2.3 Induced effect of streamline adjustment

After polymer flooding, heterogeneous combination flooding could only increase the sweep area of the main streamline area, but continuous residual oil still existed in the non-streamline area. This part of the remaining oil may be moved by further streamline transformation. Figure 5 shows the remaining oil distribution of experiment 3. As depicted in Fig. 5a, it can be seen that the distribution characteristics after polymer flooding were consistent with the above analysis. That is, the main streamline area was dominated by the isolated island state, and the continuous state form dominated the non-main streamline area. As observed from Fig. 5b, it can be seen that after well-pattern adjustment and heterogeneous combination flooding, the sweep area was further improved. The remaining oil was mainly distributed in the non-main streamline. Most of the remaining oil was in the isolated island state, and there was no contiguous state oil. The difference between experiments 3 and 2 shows the superiority of the heterogeneous combination flooding with streamline adjustment. Streamline adjustment plays a major role in an “induced effect”; that is, it changes the direction of fluid flow, leading the chemical agents to the non-main streamline area.

3.2.4 Comparison of the recovery percent

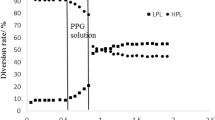

In order to identify the development effect under different strategies, the cumulative recovery percent and process recovery percent of each experiment were statistically analyzed, as shown in Fig. 6. The moment after polymer flooding was selected as the starting point for study, from which the cumulative recovery percent gradually increased. The cumulative recovery percent of SA/HCF scheme was 9.0% higher than that of HCF scheme, where the induced effect of streamline adjustment could enhance the acting area of the HCF system. For either the SA/HCF scheme or the HCF scheme, water flooding is the main strategy for further oil recovery.

3.3 Contributions of different factors in the hybrid strategy

In order to quantitatively characterize the contributions of the four factors in the hybrid strategy, single-factor comparison experiments were conducted. Experiments 4, 5, 6 and 7 were used for single-factor comparison.

3.3.1 Contribution of streamline adjustment

Figure 7 shows the remaining oil distribution of experiment 4 at the end of polymer flooding and water flooding after streamline adjustment, respectively. It can be seen that new main streamlines took shape, and the remaining oil became more dispersed, and the amount of isolate-island state oil increased significantly. It indicated that the streamline adjustment in hybrid development strategy has the induced effect for the injected fluid to displace the potential remaining oil. Moreover, the EOR effect of streamline adjustment was more obvious for actual post-polymer flooding reservoirs with strong vertical heterogeneity. Based on the results obtained from experiment 4, with the single method of streamline adjustment, the injected fluid still flows along the channel formed after the polymer flooding. So, the polymer and other chemicals are required to increase the viscosity of the injected fluid and thus improve the displacement efficiency for further enhanced oil recovery for post-polymer reservoirs.

3.3.2 Contribution of surfactant

Figure 8 shows the remaining oil distribution of experiment 5 at the end of polymer flooding and water flooding after streamline-adjustment-assisted surfactant flooding, respectively. Surfactant could reduce residual oil in the swept area and improve the displacement efficiency. As shown in Fig. 8b, the remaining oil became more dispersed and the remaining oil area was decreased. That is because the injected surfactant solution is miscible with oil, causing an emulsion to be formed around the edge of remaining oil area. Due to low viscosity, the surfactant solution can readily flow through the highly permeable channels and cannot displace the oil efficiently, which results in the wide distribution of isolated island state oil between the injection and production wells. Besides, the skidding mechanism of surfactant strengthens the channeling velocity. The surfactant can increase the displacement efficiency, but has no positive impact on the sweep efficiency improvement. Thereby, profile control agents should be added to increase the viscosity of the injected fluid by improving the sweep efficiency.

3.3.3 Contribution of polymer and B-PPG particles

B-PPG particles and polymer are profile control agents in the hybrid strategy. Figure 9 shows the remaining oil distribution after streamline adjustment combined with secondary polymer flooding (see experiment 6). Figure 10 shows the remaining oil distribution after streamline adjustment combined with B-PPG flooding (see experiment 7). The remaining oil distribution of the two experiments is similar. As observed in Figs. 9b and 10b, both the polymer solution and the B-PPG suspension system achieved good displacement efficiency in the swept area. Compared with experiments 4 and 5, the amount of remaining oil in an isolated island state had been decreased significantly in experiments 6 and 7. Both the polymer solution and the B-PPG suspension system had the ability to divert fluid, and the diverted fluids prefer to flow toward the production wells in channels with smaller resistance formed during previous first polymer flooding, which resulted in the occurrence of some oil as continuous state locating in the newly formed non-main streamline area. The distribution characteristics of the remaining oil indicate that it is difficult for the profile control system to travel through the porous medium due to its residual resistance mechanism. Therefore, a surfactant is required in the polymer solution and the B-PPG system to improve the transport ability, avoiding destructive blockage and thus enhancing the sweep efficiency. From the above analysis, it is concluded that the synergistic effect of B-PPG particles, polymer and surfactant can achieve good development effect.

Different factors in the hybrid strategy have different EOR mechanisms. Thus, the four factors in the hybrid strategy can be combined and used to further enhance the oil recovery of post-polymer flooding reservoirs.

3.3.4 Comparison of the degrees of contribution

In order to identify the development effect of different methods, EOR values of different experiments and the relative contributions of different factors were statistically analyzed. The effect of streamline-adjustment-assisted heterogeneous combination flooding on EOR is divided into four factors, i.e., streamline adjustment synergism (SA), surfactant synergism (S), polymer synergism (P) and B-PPG synergism (B-PPG). Quantitative value of the contribution degree of four factors is calculated as:

where Xi represents the contribution degree of factor i, i=1, 2, 3, 4 (representing SA, S, P and B-PPG). R1 represents the increased recovery percent of the streamline adjustment factor, which is the difference of recovery percent between experiment 4 and experiment 1. R2 represents the increased recovery percent of the surfactant factor, which is the difference of recovery percent between experiment 5 and experiment 4. R3 represents the increased recovery percent of the polymer factor, which is the difference of recovery percent between experiment 6 and experiment 4. R4 represents the increased recovery percent of the B-PPG factor, which is the difference of recovery percent between experiment 7 and experiment 4.

The difference of recovery percent between experiment 4 and experiment 1 was 6.9%. Compared with experiment 4, the recovery degree of experiment 5, experiment 6 and experiment 7 increased by 5.0%, 7.0%, and 9.9%, respectively. The increased values of different experiments and contributions of different factors are shown in Fig. 11. Based on the experiments, the contribution degree of branched preformed particle gels (B-PPG), polymer and surfactant was 34.4%; 24.3% and 17.4%, respectively; the contribution degree of streamline adjustment was calculated as 23.9%.

4 Conclusions

-

1.

After the polymer flooding, the remaining oil was distributed discontinuously in an isolated island state in the main streamline area and as a continuous state in the non-main streamline area. Compared with water flooding, polymer flooding dispersed more residual oil, and more thief seepage channels were observed.

-

2.

During the heterogeneous combination flooding, the distribution of remaining oil in the main streamline area was obviously changed from an isolated island state to a continuous state because of the synergistic effect among chemicals. As the solid phase possessing viscoelastic properties, B-PPG particles suspended in the solution could deform and flow in the physical model to play a role in fluid diversion. Fluid diversion happened all over the process and expanded the sweep coefficient significantly. As the liquid phase in heterogeneous combination flooding, polymer increased the system viscosity and surfactant improved the displacement efficiency. Besides, polymer and surfactant helped B-PPG travel through the porous medium and avoid destructive blockages. The heterogeneous combination flooding without streamline adjustment could improve the sweep efficiency and displacement efficiency in the main streamline area between the injection and production wells, but the development performance was not so good in the non-main streamline area.

-

3.

After the hybrid strategy including streamline adjustment and heterogeneous combination flooding, there was hardly any remaining oil distributed in the main streamline area and only a small amount of remaining oil located in the non-main streamline area mainly in an isolated island state. Streamline adjustment could guide the suspended chemical solution to the non-main streamline area, which was beneficial for the chemicals to fully play the role for displacing remaining oil into larger areas after polymer flooding. Compared with the heterogeneous combination flooding without streamline adjustment, the hybrid strategy had better sweep efficiency and displacement efficiency for post-polymer flooding reservoirs. The cumulative recovery percent of the SA/HCF scheme was 9.0% higher than that of the HCF scheme.

-

4.

In the hybrid strategy, the fluid diverting mechanism of B-PPG had the biggest contribution of 34.4%. The profile control of polymer and the induced effect of streamline adjustment had the contribution of 24.3% and 23.9%, respectively. The surfactant had the smallest contribution of 17.4% in improving oil displacement efficiency.

References

Al-Ibadi A, Civan F. Experimental investigation and correlation of treatment in weak and high-permeability formations by use of gel particles. SPE Prod Oper. 2013;28:387–401. https://doi.org/10.2118/153557-PA.

Bai BJ, Liu YZ, Coste JP, et al. Preformed particle gel for conformance control: transport mechanism through porous media. SPE Reserv Eval Eng. 2007;10(2):176–84. https://doi.org/10.2118/89468-PA.

Chang HL, Zhang ZQ, Wang QM, et al. Advances in polymer flooding and alkaline/surfactant/polymer processes as developed and applied in the People’s Republic of China. J Pet Technol. 2006;58(2):84–9. https://doi.org/10.2118/89175-JPT.

Choi SK, Sharma MM, Bryant S, et al. pH-Sensitive polymers for novel conformance-control and polymer-flood applications. SPE Reserv Eval Eng. 2010;13(6):926–39. https://doi.org/10.2118/121686-PA.

Cipolla CL, Kyte DG. Infill drilling in the Moxa Arch: a case history of the frontier formation. In: SPE annual technical conference and exhibition, 4–7 October. Washington, D.C., USA; 1992. https://doi.org/10.2118/24909-MS.

Coste JP, Liu Y, Bai B, et al. In-depth fluid diversion by pre-gelled particles. Laboratory study and pilot testing. In: SPE/DOE improved oil recovery symposium, 3–5 April, Tulsa, Oklahoma, USA; 2000 https://doi.org/10.2118/59362-MS.

Cui XH, Li ZQ, Cao XL, et al. A novel PPG enhanced surfactant-polymer system for EOR. In: SPE enhanced oil recovery conference, 19–21 July, Kuala Lumpur, Malaysia; 2011. https://doi.org/10.2118/143506-MS.

Elsharafi MO, Bai B. Effect of weak preformed particle gel on unswept oil zones/areas during conformance control treatments. Ind Eng Chem Res. 2012;51(35):11547–54. https://doi.org/10.1021/ie3007227.

Flores JG., Gaviria W, Lorenzon JR, et al. New life for a mature oil province via a massive infill drilling program. In: International oil conference and exhibition in Mexico, August 31–September 2, Cancun, Mexico; 2006. https://doi.org/10.2118/104034-MS.

Goudarzi A, Zhang H, Varavei A, et al. A laboratory and simulation study of preformed particle gels for water conformance control. Fuel. 2014;140:502–13. https://doi.org/10.1016/j.fuel.2014.09.081.

Gould TL, Sarem AM. Infill drilling for incremental recovery. J Pet Technol. 1989;41(3):229–37. https://doi.org/10.2118/18941-PA.

Han M, Alshehri AJ, Krinis D, et al. State-of-the-art of in-depth fluid diversion technology: enhancing reservoir oil recovery by gel treatments. In: SPE Saudi Arabia section technical symposium and exhibition, 21–24 April, Al-Khobar, Saudi Arabia; 2014. https://doi.org/10.2118/172186-MS.

Hou J. Network modeling of residual oil displacement after polymer flooding. J Pet Sci Eng. 2007;59(3):321–32. https://doi.org/10.1016/j.petrol.2007.04.012.

Hou J, Li ZQ, Zhang SK, et al. Computerized tomography study of the microscopic flow mechanism of polymer flooding. Transp Porous Media. 2009;79(3):407–18. https://doi.org/10.1007/s11242-008-9330-9.

Hou J, Pan GM, Lu XJ, et al. The distribution characteristics of additional extracted oil displaced by surfactant–polymer flooding and its genetic mechanisms. J Pet Sci Eng. 2013;112:322–34. https://doi.org/10.1016/j.petrol.2013.11.021.

Lin HL, Liu WH, Shen KS, et al. Weak gel behaviour of poly (vinyl alcohol)-borax aqueous solutions. J Polym Res. 2003;10(3):171–9. https://doi.org/10.1023/A:1026060630998.

Maghzi A, Kharrat R, Mohebbi A, et al. The impact of silica nanoparticles on the performance of polymer solution in presence of salts in polymer flooding for heavy oil recovery. Fuel. 2014;123:123–32. https://doi.org/10.1016/j.fuel.2014.01.017.

Muhammed FA, Bai BJ, Tang TJ. Experimental study of the interaction between surfactants and super absorbent polymer gel. J Pet Sci Eng. 2012;90:159–64. https://doi.org/10.1016/j.petrol.2012.04.010.

Pirayesh E, Jamali A, Soliman MY. Enhancing volumetric sweep efficiency in waterfloods using in-situ non-conductive barrier fractures. J Pet Sci Eng. 2014;122:119–33. https://doi.org/10.1016/j.petrol.2014.06.026.

Ranganathan R, Lewis R, McCool CS, et al. Experimental study of the gelation behavior of a polyacrylamide/aluminum citrate colloidal-dispersion gel system. SPE J. 1998;3(4):337–43. https://doi.org/10.2118/52503-PA.

Renouf G. A survey of polymer flooding in western Canada. In: SPE improved oil recovery symposium, 12–16 April, Tulsa, Oklahoma, USA; 2014. https://doi.org/10.2118/169062-MS.

Rose P, Pyle J, Barker G, et al. Forties infill drilling eight years on; Continued success through the application of thorough development geoscience driven by 4D seismic. In: Offshore Europe, 6–8 September, Aberdeen, UK; 2011. https://doi.org/10.2118/145433-MS.

Sang Q, Li YJ, Yu L, et al. Enhanced oil recovery by branched-preformed particle gel injection in parallel-sandpack models. Fuel. 2014;136:295–306. https://doi.org/10.1016/j.fuel.2014.07.065.

Sayyafzadeh M, Pourafshari P, Rashidi F. Increasing ultimate oil recovery by infill drilling and converting weak production wells to injection wells using streamline simulation. In: International oil and gas conference and exhibition in China, 8–10 June, Beijing, China; 2010. https://doi.org/10.2118/132125-MS.

Shi JT, Varavei A, Huh C, et al. Viscosity model of preformed microgels for conformance and mobility control. Energy Fuels. 2011;25(11):5033–7. https://doi.org/10.1021/ef200408u.

Urbissinova T, Trivedi JJ, Kuru E. Effect of elasticity during viscoelastic polymer flooding-a possible mechanism of increasing the sweep efficiency. In: SPE western regional meeting, 27–29 May, Anaheim, California, USA; 2010. https://doi.org/10.2118/133471-MS.

Wang HY, Cao XL, Zhang JC, et al. Development and application of dilute surfactant-polymer flooding system for Shengli oilfield. J Pet Sci Eng. 2009;65(1):45–50. https://doi.org/10.1016/j.petrol.2008.12.021.

Wang W, Gu Y, Liu Y. Applications of weak gel for in-depth profile modification and oil displacement. J Can Pet Technol. 2003;42(6):54–61. https://doi.org/10.2118/03-06-04.

Wever DAZ, Picchioni F, Broekhuis AA. Comblike polyacrylamides as flooding agent in enhanced oil recovery. Ind Eng Chem Res. 2013;52(46):16352–63. https://doi.org/10.1021/ie402526k.

Wu CH, Laughlin BA, Jardon M. Infill drilling enhances waterflood recovery. J Pet Technol. 1989;41(10):1088–95. https://doi.org/10.2118/17286-PA.

You Q, Tang YC, Dai CL, et al. Research on a new profile control agent: dispersed particle gel. In: SPE enhanced oil recovery conference, 19–21 July, Kuala Lumpur, Malaysia; 2011. https://doi.org/10.2118/143514-MS.

Zhang XQ, Guan WT, Pan F. Improving recovery efficiency of polymer flooding for middle and low permeability reservoirs in Daqing oilfield. In: SPE Asia Pacific oil & gas conference and exhibition, 14–16 October, Adelaide, Australia; 2014. https://doi.org/10.2118/171462-MS.

Zhou XD, Dong MZ, Maini B. The dominant mechanism of enhanced heavy oil recovery by chemical flooding in a two-dimensional physical model. Fuel. 2013;108:261–8. https://doi.org/10.1016/j.fuel.2013.02.012.

Acknowledgements

The authors greatly appreciate the financial support from the National Natural Science Foundation of China (Grant No. 51574269), the National Science Foundation for Distinguished Young Scholars of China (Grant No. 51625403), the Important National Science and Technology Specific Projects of China (Grant No. 2016ZX05025-003), the Fundamental Research Funds for the Central Universities (Grant No. 15CX08004A, 18CX02169A), China Postdoctoral Science Foundation (Grant No. 2017M622319), and the Natural Science Foundation of Shandong Province (Grant No. ZR2018BEE004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Edited by Yan-Hua Sun

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Du, QJ., Pan, GM., Hou, J. et al. Study of the mechanisms of streamline-adjustment-assisted heterogeneous combination flooding for enhanced oil recovery for post-polymer-flooded reservoirs. Pet. Sci. 16, 606–618 (2019). https://doi.org/10.1007/s12182-019-0311-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12182-019-0311-0