Abstract

The accumulation of organophosphorus type herbicides has been observed worldwide in the environment (i.e. soil, water), together with their appearance in foods of plant origin. This paper reports a new liquid chromatography–isotope dilution–tandem mass spectrometric method (LC-IDMS) for the analysis of glufosinate (GLUF), glyphosate (GLY) and its main metabolite, aminomethylphosphonic acid (AMPA), in challenging food samples. Sample preparation is based on aqueous extraction with ethylenediaminetetraacetic acid solution, followed by solid-phase extraction (SPE) on mixed-mode cation exchange cartridges to remove matrix constituents before derivatization with 9-fluorenylmethoxycarbonyl chloride (FMOC-Cl). Derivatized samples were cleaned up on hydrophilic modified polymeric SPE cartridge. This two-step SPE supported sample preparation approach, and the LC-IDMS separation carried out in negative ionization mode resulted in fit-for-purpose recovery (81–118%) and precision (4–18%) in the validation of glutamate loaded spice mix, mushroom, maize and cherry samples. Amino acid content influencing FMOC derivatization efficiency was estimated with a HILIC-MS/MS setup. Multiple reaction monitoring (MRM) was assisted with high-resolution (QTOF) accurate mass data on the FMOC-derivatized GLUF, GLY and AMPA standards. The limit of quantification (LOQ) was 0.005 mg/kg for all the three analytes. The method was successfully applied on quality control samples (oat and arugula) with fit-for-purpose accuracy (99–120%) and on other nineteen real samples, where GLY and AMPA were detected in the range between 0.005 and 0.069 mg/kg.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In accordance with the Herbicide Resistance Action Committee (HRAC), glyphosate (GLY) and glufosinate (GLUF) are organic phosphoric acid (aminophosphonate) type herbicides (Table 1) that inhibit the metabolic pathway of aromatic amino acids of green plants (HRAC 2021). They are commonly used for weed control (ECHA 2021). GLY and GLUF are hydrophilic and stable compounds; their residues are usually present in water and soil after their application, which evokes a great environmental concern (EPA 2016). On the other hand, these polar herbicides (QuPPE 2019; Golge 2021) can thus appear in foods of plant origin resulting in a health concern as well (Ding et al. 2016). The European Commission (EC) therefore set maximum residue limits (MRLs) for GLY (Commission Regulation (EU) 2013/293 (2013) and MRLs for sum of GLUF, its isomers, metabolites and N-acetyl-GLUF (Commission Regulation (EU) 2016/1002 (2016). MRLs widely vary from 0.03 mg/kg to 20 mg/kg depending on food matrices; the lower MRLs (≤ 0.1 mg/kg) correspond to products in which MRLs relate to the lower limit of analytical determination. GLY and GLUF have indicative MRLs in spices and mushroom as low as 0.1 mg/kg, while in maize, GLY and GLUF have applicable MRL as 1 mg/kg and 0.1 mg/kg, respectively. On the other hand, aminomethylphosphonic acid (AMPA), the main metabolite of GLY, has no MRLs so far. Even though these herbicides are not carcinogenic, the European Chemical Agency (ECHA) and the European Food Safety Authority (EFSA) have been reconsidering their related opinion on GLY (ECHA 2021). GLY is currently authorized for use in the EU until December 2022 (ECHA 2021).

The analytical determination of GLY and GLUF by HPLC is challenging due to their highly polar structure (Table 1). According to EU Reference Laboratories methods (QuPPE 2019), anion exchange columns or porous graphite carbon stationary phases have mostly been addressed for GLY, GLUF and AMPA. Porous graphite carbon HPLC columns need to be thoroughly primed before application with a number of injections of spinach extract containing planar molecules (QuPPE 2019), so its use can be considered complicated and laborious. Anion exchange separation requires phosphate buffer as an eluent additive, which usually fits optical (fluorescent) detection (García de Llasera et al. 2005). Indeed, recent publications highlight that liquid chromatography–tandem mass spectrometry (LC–MS/MS) is the most suitable technique for GLY, GLUF and AMPA determination in complex food samples (Avino et al. 2020; Cruz and Murray 2021; Kolakowski et al. 2020; QuPPE 2019; Steinborn et al. 2016; Tóth et al. 2022). As conventional reversed-phase (RP) HPLC columns provide no retention for GLY, GLUF and AMPA due to their highly hydrophilic character, pre-column derivatization with 9-fluorenylmethoxycarbonyl chloride (FMOC-Cl) or dansyl chloride has been consequently introduced (Arkan and Molnár-Perl 2015; Jansons et al. 2021). The derivatized compounds (Table 1) have appropriate retention on RP columns and have high sensitivity under LC–MS/MS conditions (Cruz and Murray 2021; Kolakowski et al. 2020; Zhang et al. 2020). Alternatively, hydrophilic interaction liquid chromatographic (HILIC) separation can be used, which allows the analysis in their native forms; however, this might require special HILIC columns suitable for alkaline pH conditions (Chen et al. 2013; Jiang et al. 2012), an instrument with high sensitivity due to the high dilution factor applied in the sample preparation (Lopez et al. 2020) or restrictions on ion source polarity settings (Vass et al. 2016). Moreover, HILIC does not allow for as many sample loads as the RP-HPLC setups and has usually low robustness (Botero-Coy et al. 2013), especially in terms of column conditioning.

Methanol and water are both appropriate solvents for the extraction of GLY, GLUF and AMPA; the extraction can be enhanced by adjusting the extraction medium pH to obtain the molecules in less (QuPPE 2019) or more hydrophilic (Ehling and Reddy 2015; Li et al. 2007) form. The co-extracted non-polar matrix constituents can be removed from the water-based extract with a liquid–liquid extraction (LLE) using immiscible dichloromethane. This step can also reduce the concentration of matrix solutes that can react with the derivatization agent if derivatization is addressed.

Conventional sample purification techniques of aminophosphonate type pesticides such as solid-phase extraction (SPE) or LLE cannot be easily carried out because of their highly polar character in native form. Indeed, the main interfering matrix constituents such as amino acids, peptides, proteins or other polar solutes with anionic or basic characters cannot be straightforwardly removed because aminophosphonates possess the structure similar to zwitterionic amino acids (Table 1). For example, strong anion exchange (SAX) SPE cartridges co-accumulate the analytes with acidic matrix constituents, which disturbs the subsequent separation on a non-orthogonal SAX HPLC column (Steinborn et al. 2016). Pre-column derivatization makes these target analytes less hydrophilic (Table 1), so they will have appropriate retention on RP SPE cartridges (Arkan and Molnár-Perl 2015; Jansons et al. 2021). Generally, room temperature is appropriate for the derivatization; higher temperature would increase the reaction rate between FMOC-Cl and matrix constituents that are present in much higher concentration compared to target compounds (Li et al. 2007; Liao et al. 2018). Although derivatization makes the sample preparation longer, it is usually the only option left in case low concentration (< 0.1 mg/kg) of GLY, GLUF and AMPA is faced (Schrübbers et al. 2016).

In our study a liquid chromatography–isotope dilution mass spectrometry (LC-IDMS) method was developed for the determination of GLY, GLUF and the AMPA, with the focus on challenging spice mix samples. Indeed, earlier reports based on pre-column derivatization of aminophosphonate type pesticides mostly targeted cereal- or milk-based foods (Ehling and Reddy 2015; Goscinny et al. 2012; Li et al. 2007; Liao et al. 2018; Oulkar et al. 2017; Tittlemier et al. 2017). As no previous fragmentation data on these FMOC-derivatized analytes have been published to the best of our knowledge, the selection of MRM transitions was assisted with high-resolution mass spectrometry to fit possible future requirements on 13C and/or 15N labelling (Mairinger and Hann 2017). Method development was carried out using spice mixes with high load of the flavour intensifier, sodium glutamate, showing similar chemical structure and character to the investigated compounds; accordingly, the entire approach required thorough optimization to obtain fit-for-purpose analytical performance characteristics. Further goal was to validate the method for those samples (mushroom, maize, cherry, peach and sour cherry) received frequently for analysis, including quality control (QC) samples as well.

Materials and Methods

Reagents and Samples

Both native and isotopically labelled (GLY(13C, 15N), GLUF-d3, AMPA(13C, 15N)) analytical standards were obtained from LGC (Wesel, Germany). Stock solutions of GLY(13C, 15N) and GLUF-d3 (1 mg/mL) were prepared by dissolving 10.0 mg standard in 10.0 mL water and were kept at 4 °C for a year, while AMPA(13C, 15N) was obtained in 100 µg/mL concentration in water and stored under the same conditions. Working standard mixture solution including the native standards for calibration and spiking purposes was prepared at 10 µg/mL concentration in water. Also, an internal standard (ISTD) mixture solution containing the labelled analogues was prepared at 1 µg/mL concentration in water. These solutions were stored at 4 °C for 3 months. Amino acids, namely, glycine, L-alanine, L-arginine, L-aspartic acid, L-cystine, L-glutamic acid, L-histidine, L-isoleucine, L-leucine, L-lysine, L-methionine, L-phenylalanine, L-proline, L-serine, L-threonine, L-tyrosine and L-valine were of a.r. grade and were purchased from Reanal Laborvegyszer Kft. (Budapest, Hungary). Methanol, acetonitrile, ammonium formate, ammonium acetate (either LC–MS or HPLC grade), 9-fluorenylmethoxycarbonyl chloride (FMOC-Cl), hydrochloric acid (37%), sodium borate, ethylenediaminetetraacetic acid disodium salt dihydrate (Na2-EDTA x 2H2O) and the Ascentis Express C18 HPLC column (packed with C18 fused-core material; 100 mm × 3 mm, 2.7 µm) were purchased from the Merck-Sigma group (Schnelldorf, Germany). TSKgel Amide-80 (100 mm × 3 mm, 3 µm) column was obtained from Tosoh Bioscience GmbH (Griesheim, Germany). HPLC gradient grade water was obtained from VWR International Ltd (Debrecen, Hungary). Strata Screen-C (3 mL/200 mg), Strata-XL-C (3 mL/200 mg) and Strata-XL (3 mL/60 mg or 6 mL/200 mg) SPE cartridges, hydrophilic PTFE syringe filters (13 mm, 0.45 µm), HPLC pre-column holders and C18 pre-column cartridges (4 mm × 3 mm; 5 µm) were obtained from Phenomenex (Torrance, CA, USA). BEH C18 RP UPLC column (100 mm × 2.1 mm × 1.7 μm) was purchased from Waters (Waters Ltd.; Milford, MA, USA).

The Food Analysis Performance Assessment Scheme (FAPAS) (Fera Science Ltd., Sand Hutton, York, UK) oat QC sample (Test material # 09130) and arugula (Eruca vesicaria; QC (# 147) sample (Testqual, Murcia, Spain) were stored at − 18 °C. Sample preparation was optimized with a spice mix that was previously checked for GLY contamination and was assigned with an approximate GLY content of 0.1 mg/kg. This spice mix contained the following ingredients: fifteen different spices and herbs (i.e., paprika, onions, peppers, marjoram, rosemary, bay leaf, nutmeg), sodium glutamate as flavour intensifier, sugar, salt and a claimed protein content of 9.3%.

The nineteen real samples, analysed with the final method, included ten spice mixes, three fresh white button mushroom, one fresh cherry, one fresh peach and four fresh sour cherry lots. Maize samples were grounded and dry as compound feed. Mushrooms and fruits were stored at + 4 °C until analyses.

Instrumentation

LC–MS/MS analyses were carried out on a Shimadzu Nexera LC-30AD liquid chromatograph, consisting of a SIL-30AC autosampler, CTO-20AC column oven and CBM-20A communications bus module (Shimadzu Corporation, Kyoto, Japan), coupled to either a QTRAP 6500 triple quad MS detector equipped with a Turbo V Source (Sciex; Warrington, Cheshire, UK) or a QTRAP 6500 + instrument equipped with an IonDrive Turbo V Source (Sciex). Data acquisition and evaluation were performed with the Analyst software version 1.7.1 and MultiQuant software version 3.0.3, respectively (Sciex).

For high-resolution experiments, a Vion ion mobility QTOF-MS (Waters) equipped either with a UniSpray or an ESI ion spray source was coupled to an Acquity UPLC I-Class system (Waters). Data evaluation was carried out with the help of the Unifi software (version 1.9.4; Waters).

Sample blending was performed with a GM 200 device (Retsch GmbH, Haan, Germany). Sample shaking and centrifugation were done using a CAT S50 flask shaker (M. Zipperer GmbH, Ballrechten-Dottingen, Germany) and a Jouan B4i centrifuge (Thermo Fisher Scientific, Budapest, Hungary), respectively. Sample evaporation was carried out by TurboVap II (Biotage, Uppsala, Sweden). LogP (octanol–water partitioning coefficient) and pKa values (acid/base dissociation constant) were calculated using Pallas 2.1 (CompuDrug Chemistry Ltd., FL, USA).

Sample Preparation

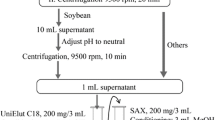

Sample Extraction and Freezing out

Finely grounded (< 1 mm) samples (2.00 g) were weighted in 50.0 mL polypropylene (PP) centrifuge tubes, and 20 mL of 0.1 M EDTA solution (pH 5, set with diluted HCl) was added. Tubes were capped and vortex-mixed for 10 s, followed by shaking at 700 min−1 for 30 min. After the extraction, samples were centrifuged at ambient temperature for 10 min at 2800 g, and aliquots of the upper layers (~ 5 mL) were collected in 15 mL PP tubes and were frozen out at − 18 °C overnight. Alternatively, after extraction, the samples were let settle down for 5 min, and 4-mL (twice 2 mL) upper layers were collected in 2 mL Eppendorf tubes and centrifuged at − 10 °C for 30 min at 8000 g. The low-temperature centrifugation was preferred if samples were taken for urgent analysis.

SPE Method #1 and Derivatization

Sample extracts were thawed and subjected to SPE clean-up on either Strata Screen-C or Strata-XL-C cartridges (3 mL/200 mg). The cartridges were conditioned with 3 mL methanol, followed by 3 mL water, and then they were dried under vacuum. An aliquot of thawed sample extracts (3 mL, equal to 300 mg sample) was loaded onto the cartridges, and the effluents were collected in 15 mL PP tubes. The cartridges were dried under vacuum.

ISTD mixture (30 µL, 1 µg/mL), 2 mL sodium borate buffer (pH = 9) and 0.5 mL derivatization agent (FMOC-Cl, 1 mg/mL in acetonitrile) were added to the PP tubes, followed by immediate vortex-mixing. Samples were derivatized at 25 °C for 30 min without shaking; the reaction was finally stopped by adding 0.5 mL 2 M HCl solution, followed by vortex-mixing, to decrease sample pH to 2.5.

SPE Method #2

Derivatized samples were subjected to a second SPE clean-up using Strata-XL (3 mL/60 mg or 6 mL/200 mg) cartridges. Cartridges were conditioned with 2 × 3 mL methanol, followed by 2 × 3 mL water. The total volume of derivatized samples (~ 6 mL) were loaded onto the cartridges and passed through dropwise; afterwards the cartridges were washed with 2 × 3 mL water. Cartridges were then dried under vacuum before eluting the samples with 2 × 2.5 mL methanol into glass tubes. The eluted samples were evaporated until dryness at 45 °C under a gentle stream of nitrogen. Sample residues were reconstituted in 1000 µL water by vortex-mixing for 15 s. Finally, samples were filtered through hydrophilic PTFE syringe filters into HPLC vials. This preparation resulted in a sample dilution factor of 3.33.

Alternatively, SPE method #2 was eliminated from the sample preparation; however, in this case, a higher injection volume (30 µL) was used.

Optimization of the LC–MS/MS Detection

An aliquot (3 mL) of the working standard mixture and ISTD mixture solutions were derivatized and cleaned up as written above. These solutions were used for fine-tuning the ion transitions using the compound optimization mode in the Analyst software and were used for recording the QTOF mass spectra and for post-spiking extracted blank samples for evaluating the matrix effect (ME). At least three ion transitions were tuned for each compound in both positive and negative ionization modes.

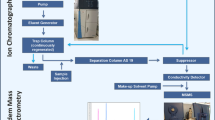

LC-IDMS Determination

Target compounds were separated on an Ascentis Express C18 HPLC column. Binary gradient elution mode was applied with solvent A containing 20 mM ammonium formate in water and solvent B containing acetonitrile. The mobile phase gradient consisted of 10% B at 0 min; 10% B at 1.0 min; 40% B at 5.0 min; 95% B at 5.1 min; 95% B at 9.0 min; 10% B at 9.1 min; and 10% B at 12.0 min; flow rate was set to 0.5 mL/min. The column thermostat and autosampler were maintained at 25 °C. The injection volume was 10 µL. Compounds were detected in negative ionization mode by multiple reaction monitoring (MRM) scan mode (Tables 2 and 3; during the method development, the positive ionization mode was also tested). Ion source parameters were as follows: curtain gas 40 unit, gas1 35 unit, gas2 35 unit, drying gas temperature 350 °C, ion spray voltage − 4500 V and interface heater ‘on’. The HPLC effluent entered the ion source only in the retention time window between 3–6 min.

Six-point matrix-matched calibration curve was prepared for each matrix. Blank samples were spiked with the native working standard solution and the internal standard solution at the beginning of sample preparation. The calibration levels were as follows: 0.005, 0.050, 0.100, 0.500, 1.000 and 2.000 mg/kg. ISTD concentration was 0.100 mg/kg. The mass fraction of analytes (mg/kg) could be directly obtained from the equation of linear calibrations weighted with the factor of 1/x. In this concentration range, for each compound and in all matrices, determination coefficients obtained under the validation study were not lower than 0.9985. Calibrants were stable at least for 3 months at + 4 °C.

LC–MS/MS Determination of Free Amino Acids

Semi-quantitative determination of free and native amino acids in the spice mix extract obtained after carrying out the SPE method #1 was done with HILIC separation on a TSKgel Amide-80 column according to Lane (2015). Single-point calibration using a mix of amino acid standards (each at 1 µg/ml concentration) was used.

UPLC-QTOF-MS Analysis

UPLC-QTOF-MS analysis was carried out using BEH C18 RP UPLC columns (100 mm × 2.1 mm × 1.7 μm and 50 mm × 2.1 mm × 1.7 μm; Waters). Deionized water with 10 mM ammonium acetate (A) and acetonitrile:water (9:1 V/V) with 10 mM ammonium acetate (B) were used as mobile phases at the flow rate of 0.4 mL/min. The column was kept at 40 °C. Gradient elution program was applied as follows: 0–1 min 10% B, 1–5 min up to 80% B, 5–6 min 80% B, 6–6.1 min down to 10% B and 6.1–8 min 10% B. FMOC-derivatized standard solutions (5 µg/mL) were injected (1 µL). UniSpray ion source was used in positive (for GLY, GLUF and AMPA) and negative (for GLY and GLUF) ionization modes either in MSE or MSE → MSMS functions, while ESI ion source was used in negative mode for AMPA (Fig. 1a, b and c and supplementary Fig. S1–11). Related instrumental parameters are described in the supplementary Table-S1.

Method Validation

Blank samples were spiked with native target compounds at two concentration levels for each matrix: 10 spikes were done at 0.05 mg/kg level and 10 spikes at 0.10 mg/kg level on another day by two operators. During the method development process, different freezing out approaches and SPE cartridges (Strata Screen-C or Strata-XL-C; Strata-XL with 60 mg or 200 mg adsorbent mass) were used as detailed in SPE Method #1 and Derivatization and SPE Method #2 sections. The results obtained from the ten replicates at each level were evaluated together for each matrix, and recovery, within-laboratory precision (RSD%) data were calculated.

Results and Discussion

LC–MS/MS Detection of Derivatized Target Analytes

Tables 2 and 3 present the MRM transitions tuned for each compound in both positive and negative ionization modes, while the arising fragment ions are shown in Table 4 and Fig. 1a, b and c and supplementary Fig. S7–11. For the assignment of fragment composition and structures, high-resolution data had to be taken into account (Table 4). For the three analytes, positive ionization showed higher detector responses due to the FMOC group that provided intense product ions (Arkan and Molnár-Perl 2015; Ramesh et al. 2011). However, FMOC-derivatized matrices in food samples also possess the FMOC-related product ions because of primary and/or secondary amine-containing compounds, which decreased the selectivity of MS/MS detection in positive ion mode (supplementary Fig. S12). Indeed, the protonated molecules of the native analyte residues appeared as product ions (GLY, m/z 392 > 170; GLUF, m/z 404 > 182; AMPA, m/z 334 > 112), but these transitions showed low signal-to-noise levels. In positive ionization mode, only those product ions were found selective enough in the actual spice mix sample that originated from the native analyte residues, that is, m/z 392 > 88 for GLY, m/z 404 > 136 and m/z 404 > 119 for GLUF (Table 4 and supplementary Fig. S10–11). Therefore, reproducible ion ratios for compound identification according to SANTE 2019 in positive ionization mode could only be obtained for GLUF.

The matrix effect (ME) on signal suppression/enhancement under LC–MS/MS detection was evaluated by post-spiking blank and cleaned up spice mix extracts with the derivatized working standard mixture and derivatized ISTDs (Table 5). The slopes of matrix-matched and solvent calibrations were compared to calculate the matrix effect (Matuszewski et al. 2003). Signal drop (ion suppression) of − 34% to − 57% was obtained when using external standard (ESTD) evaluation. Even though ISTD evaluation is generally aimed at compensating for the ME, this approach could not actually perform well: ion enhancement was found between + 13 and + 32% (Table 5).

It can therefore be concluded that FMOC derivatization considerably increased the number and concentration of co-eluting and FMOC-derivatized matrices (i.e., amino acids, biogenic amines or polar constituents with basic character) (supplementary Fig. S12). As these matrix-derived compounds get ionized and fragmented similarly to the analytes due to the FMOC group, low selectivity and high ME issues finally called for the use of negative ionization.

Although the FMOC residue of the FMOC-derivatized analytes didn’t provide detectable ions in the mass spectra in negative ionization mode (Table 4 and Fig. 1a, b, c), the deprotonated molecules from the native molecule residues appeared in the product ion mass spectra (GLY, m/z 390 > 168; GLUF, m/z 402 > 180; AMPA, m/z 332 > 110) (Fig. 1a, b, c). The ion transitions with ESI negative ionization mode were first tuned in MRM mode and used for quantifying the derivatized analytes in spice mixes. All the ion transitions in negative ion mode (Table 3) were free of interfering peaks in the related retention time windows; even highly concentrated matrix constituents eluting close to GLY could be resolved (Fig. 2). In negative ionization mode, the product ions are more specific and most of them derived from the native analyte residues, which was further confirmed by QTOF (Table 4 and Fig. 1a, b, c).

Extracted ion chromatograms of the derivatized target compounds (GLY-FMOC at 4.1 min, GLUF-FMOC at 4.5 min and AMPA-FMOC at 5.2 min) obtained by the optimized LC–MS/MS method in negative ionization mode. The chromatograms present a blank sample (red line) and the spiked spice mix (blue line) (spiking concentrations, 0.005, 0.050 and 0.100 mg/kg for the native forms of GLY, GLUF and AMPA, respectively). The various concentrations in the spiking solutions were chosen for the ease of presentation

Both ion suppression and enhancement were calculated using ESTD during the evaluation of ME, revealing that the ion enhancement was considerable for GLUF (Table 5); nonetheless, the ISTD evaluation could well compensate for the ME (Table 5) that made the use of negative ionization preferable. Even though the signal responses were lower in negative ionization mode, the signal-to-noise level was high, so the analytical limits, calculated from the signal-to-noise ratio (SNR), could be reduced to low µg/kg level.

When optimizing the HPLC separation, acidified eluents were first tested using formic acid in different concentrations (0.005–1.0 V/V %) as the eluent additive in the aqueous mobile phase to obtain pH from 3.4 to 2.2. The derivatized analytes possess either two or three acidic pKa values, ranging from 0.8 to 6.3 (Table 1); accordingly, they are in various molecule forms in the acidified eluents that resulted in asymmetric and distorted chromatographic peaks. The replacement of formic acid either with ammonium formate or ammonium acetate at 5–20 mM concentration in the aqueous mobile phase considerably improved the chromatographic peak shapes without decreasing the sensitivity either in positive or negative ionization mode (Fig. 2). Both ammonium formate and ammonium acetate were suitable for the separation, and sensitivity reduction was not observed up to 20 mM concentration. Zhang et al. (2020) also found improved chromatographic peak shapes and sensitivity in negative ionization mode for FMOC-derivatized GLY and GLUF when pH value closer to neutral was used.

Optimization of Sample Preparation

Sample preparation was optimized with a spice mix that was rich in ingredients (e.g., sodium glutamate) with high amino acid content possessing structures (i.e., with primary and/or secondary amine(s)) similar to the target compounds. Due to the hydrophilic character of the analytes, water-based extraction was carried out to avoid the co-extraction of lipophilic matrix constituents. GLY, GLUF and AMPA are chelating compounds and form complexes with metal ions occurring in the samples; therefore, 0.1 M EDTA in water (pH = 5) was tested for extraction at the first time. At this pH, at least two out of three acidic function groups of the analytes are dissociated, and the molecules are in highly polar form, facilitating water extraction.

Our study was aimed at using pre-column derivatization with FMOC-Cl that performs well in water samples (ISO 16308:2014 2014); however, the actual spice mix contains several matrix constituents that also react with FMOC-Cl, thus lowering the derivatization rate. When the extracted spice mix was derivatized according to ISO 16308:2014 (2014), the derivatization rate was lower than 1% if the responses are compared with those obtained after derivatization of native compounds in matrix-free solvent (buffered water). Therefore, SPE clean-up was used to remove lipophilic, neutral and basic matrix constituents from the sample before derivatization. A mixed-mode SPE cartridge (Strata Screen-C) possessing both C-8 (RP) and strong cation exchange surfaces was used to adsorb matrix compounds with primary and/or secondary amino groups. The performance of the two cartridges was not investigated since they do not adsorb these target compounds. The differences among the cartridges are related to their active surface, which are either silica-based C8 or polymeric-based for Screen-C and XL-C, respectively. Although the analytes also have basic characteristics, their dissociated acidic functional groups prevent the ionic interaction between the cartridge and the target molecules at pH 5. Hence, the washing effluents of the SPE clean-up contained the analytes relatively free from several matrix constituents with basic and/or lipophilic character. This clean-up considerably improved the conversion that almost reached 10%. Moreover, the noise level could also be reduced (Fig. 3). However, the high amount of amino acids and matrix constituents with amine groups could not be completely eliminated from the extract by SPE method #1, so they still could decrease the derivatization rate (supplementary Fig. S13). Semi-quantitative determination of free amino acids in the spice mix was carried out, and the approximate summed concentration of the investigated amino acids was 100 mg/kg (supplementary Fig. S13). Therefore, derivatization conditions (SPE method #1 and derivatization) at higher temperature, with longer derivatization time or with higher concentration of reagent, would have increased the derivatization rate of amino acids present in high concentration in the extract.

Extracted ion chromatogram of a spice mix extract spiked at 0.1 mg/kg for the native form of GLY (detected in negative ionization mode). The sample was either subjected to SPE method #1 (above) or analysed without addressing SPE method #1 (below) before derivatization. Ninety-fold lower signal-to-noise ratio was obtained without SPE method #1

At the early stage of development, the derivatization was tested by mixing the sample during derivatization according to ISO 16308:2014 (2014). In the mixed solution, the peak area of the isobaric matrix constituent, eluting close to GLY-FMOC, increased in the chromatogram with a factor of 8, while that of GLY remained at almost the same response (supplementary Fig. S14). Therefore, the derivatization in mixed solution did not support the derivatization of target compounds.

Measurements with the derivatized samples increased the backpressure on the pre-column and on the analytical column as well, possibly because of the high injection volume (30 µL), containing unreacted reactants. Therefore, the derivatized samples were cleaned up on hydrophilic modified polymeric cartridges (Strata-XL) at pH of 2.5 (see SPE Method #2 Section). This additional SPE step could eliminate all inorganic reactant (e.g., sodium borate) from the sample and allowed for the pre-concentration of the sample extracts; consequently, the injection volume could be decreased to 10 µL. After the introduction of this additional clean-up process, the backpressure on the HPLC column didn’t increase to any extent.

Validation Process

The developed LC–MS/MS method showed appropriate selectivity not only in the spice mix (Fig. 2), but also in other food samples. The method was validated for spice mix, white button mushroom, maize and cherry samples. The identification was based on ion ratios with 30% permitted tolerance (SANTE 2019), which was fulfilled in all samples. Table 6 presents the results of the validation process. Recovery ranged from 81 to 118%, and the RSD% never exceeded 18%. According to the actual SANTE guideline (SANTE 2019), the recovery shall be between 70 and 120%, and the RSD shall be ≤ 20%. Accordingly, the validation met these criteria.

The method was applied on a FAPAS oat QC sample with an assigned value of 0.435 mg/kg for GLY (z-score ± 2.0 equals to 0.279–0.593 mg/kg). The concentration obtained through the developed method was 0.441 mg/kg. A Testqual arugula QC sample (z-score ± 2.0 equals to 0.125–0.375 mg/kg) was also analysed, and 0.301 mg/kg GLY was detected. Both results were satisfactory.

After this validation, ten spice mixes, three mushroom, one cherry, one peach and four sour cherry sample lots were analysed (supplementary Table-S2). In the spice mixes, GLY and AMPA were detected. Four spice mixes contained both GLY (0.021–0.069 mg/kg) and AMPA (0.005–0.027 mg/kg). AMPA was detected alone in one spice mix (0.041 mg/kg) and in one mushroom (0.047 mg/kg). In the fruits, no analyte was detected above the LOQ. GLUF was not detected in any of the samples; however, it was found by Liao et al. (2018) in 0.0098 mg/kg in boiled potatoes, but only 1 out of 136 samples contained GLUF (Liao et al. 2018).

Method Evaluation

Determination of aminophosphonate type herbicides using pre-column derivatization with FMOC-Cl in glutamate loaded spice mixes was in the focus of our study. Such samples with high free amino acid content have never been addressed in previous reports, to the best of our knowledge (supplementary Table-S3).

Instead of using dichloromethane for LLE, we preferred using SPE clean-up after aqueous extraction with 0.1 M EDTA in water (pH = 5) and before derivatization. Also, the frozen extract enables the precipitation and removal of proteins before the derivatization step. For the derivatization itself, quite different reaction times can be found between 3 min (Tittlemier et al. 2017) and overnight (16 h) (Li et al. 2007; Liao et al. 2018). We also found that a derivatization longer than 30 min does not improve considerably the signal abundance for analytes (supplementary Table-S3). The efficiency of derivatization could be improved utilizing SPE clean-up before derivatization (Fig. 3). Li et al. (2007) pre-concentrated GLY and AMPA on SCX cartridges to clean-up various food samples before derivatization, while Zhang et al. (2020) filtered the maize extract through polymeric cartridges and collected the effluent to be derivatized. Commonly, SPE clean-up has not been used before derivatization; however, it can remove several matrix constituents that may react with FMOC-Cl, thus reducing the conversion of target compounds into their derivatized form. This was found in our study as well (Fig. 3). The second SPE aims at removing the reactant after derivatization. We also found that this SPE step, which can pre-concentrate the less polar derivatized molecules as well, is necessary to improve the HPLC separation and column lifetime. So far, only one study reported the use of a two-step SPE clean-up (Schrübbers et al. 2016), in which Coffea arabica leaves were quantified for GLY and AMPA. In our study, the first SPE was carried out with mixed-mode cation exchange cartridges rather than with RP cartridge (Schrübbers et al. 2016). The mixed-mode cation exchange cartridge removed not only the non-polar compounds, but also the matrix constituents with primary and secondary amine function groups. Therefore, they could not react with FMOC-Cl, thus did not lower the derivatization rate of target analytes. As the spice mix sample in our study consisted of several ingredients including sodium glutamate in high concentration (~ 10 mg/kg) as well, the two-step SPE purification was also needed. The clean-up was then successfully used for other food matrices possessing different endogenous matrix constituents.

Both positive and negative ionization modes are employed in the LC–MS/MS analysis of GLY, GLUF and AMPA (supplementary Table-S3). In our study, the negative ionization was preferable due to selectivity issues caused by the less specific fragmentation of FMOC derivatives in positive ionization mode (Table 3 and Fig. 1a, b and c and supplementary Fig. S1–11).

Conclusions

A new LC-IDMS method was developed for two aminophosphonate herbicides (GLY and GLUF) and a metabolite (AMPA) in complex spice mix samples utilizing pre-column derivatization for the first time. The determination involved a two-step clean-up approach, derivatization with FMOC-Cl and RP-HPLC separation, followed by MS/MS detection employing ESI negative ionization mode. The application of SPE purifications allowed high precision and low LOQs. The assignment of product ions used for MRM scan mode was supported by high-resolution (QTOF) analysis. After the successful validation of the method for various food samples, the method was applied to nineteen real samples in which GLY and AMPA could be detected below 0.1 mg/kg.

Data Availability

All data generated or analysed during this study are included in this published article (and its supplementary information files).

References

Avino P, Notardonato I, Russo MV (2020) A review of the analytical methods based on chromatography for analyzing glyphosate in foods. Pests - Classification, Management and Practical Approaches. IntechOpen https://doi.org/10.5772/intechopen.92810

Arkan T, Molnár-Perl I (2015) The role of derivatization techniques in the analysis of glyphosate and aminomethyl-phosphonic acid by chromatography. Microchem J 121:99–106. https://doi.org/10.1016/j.microc.2015.02.007

Botero-Coy AM, Ibáñez M, Sancho JV, Hernández F (2013) Direct liquid chromatography–tandem mass spectrometry determination of underivatized glyphosate in rice, maize and soybean. J Chromatogr A 1313:157–165. https://doi.org/10.1016/j.chroma.2013.07.037

Chen M-X, Cao Z-Y, Jiang Y, Zhu Z-W (2013) Direct determination of glyphosate and its major metabolite, aminomethylphosphonic acid, in fruits and vegetables by mixed-mode hydrophilic interaction/weak anion-exchange liquid chromatography coupled with electrospray tandem mass spectrometry. J Chromatogr A 1272:90–99. https://doi.org/10.1016/j.chroma.2012.11.069

Commission Regulation (EU) 2016/1002 of 17 June 2016 amending Annexes II, III and V to Regulation (EC) No 396/2005 of the European Parliament and of the Council as regards maximum residue levels for AMTT, diquat, dodine, glufosinate and tritosulfuron in or on certain products. (2016) Off J Eur Commun L 167/1. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32016R1002&from=EN

Commission Regulation (EU) No 293/2013 of 20 March 2013amending Annexes II and III to Regulation (EC) No 396/2005 of the European Parliament and of the Council as regards maximum residue levels for emamectin benzoate, etofenprox, etoxazole, flutriafol, glyphosate, phosmet, pyraclostrobin, spinosad and spirotetramat in or on certain products. (2013) Off J Eur Commun L 96/1. https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2013:096:0001:0030:en:PDF

Cruz M, Murray JA (2021) Determination of glyphosate and AMPA in oat products for the selection of candidate reference materials. Food Chem 342:128213. https://doi.org/10.1016/j.foodchem.2020.128213

Ding J, Jin G, Jin G et al (2016) Determination of underivatized glyphosate residues in plant-derived food with low matrix effect by solid phase extraction-liquid chromatography-tandem mass spectrometry. Food Anal Methods 9:2856–2863. https://doi.org/10.1007/s12161-016-0468-8

ECHA, European Chemical Agency, Glyphosate: EU regulators begin review of renewal assessments. (Accessed: 14.06.2021) https://echa.europa.eu/hu/-/glyphosate-eu-regulators-begin-review-of-renewal-assessments

Ehling S, Reddy TM (2015) Analysis of glyphosate and aminomethylphosphonic acid in nutritional ingredients and milk by derivatization with fluorenylmethyloxycarbonyl chloride and liquid chromatography−mass spectrometry. J Agric Food Chem 63:10562–10568. https://doi.org/10.1021/acs.jafc.5b04453

EPA (2016) The Environmental Protection Agency, Glyphosate issue paper: evaluation of carcinogenic potential, EPA’s Office of Pesticide Programs September 12, 2016. (Accessed: 14.06.2021) https://www.epa.gov/sites/production/files/2016-09/documents/glyphosate_issue_paper_evaluation_of_carcincogenic_potential.pdf

García de Llasera MP, Gómez-Almaraz L, Vera-Avila LE, Peña-Alvarez A (2005) Matrix solid-phase dispersion extraction and determination by high-performance liquid chromatography with fluorescence detection of residues of glyphosate and aminomethylphosphonic acid in tomato fruit. J Chromatogr A 1093:139–146. https://doi.org/10.1016/j.chroma.2005.07.063

Golge O (2021) Validation of Quick Polar Pesticides (QuPPe) Method for determination of eight polar pesticides in cherries by LC-MS/MS. Food Anal Methods 14:1432–1437. https://doi.org/10.1007/s12161-021-01966-w

Goscinny S, Unterluggauer H, Aldrian J, Hanot V, Masselter S (2012) Determination of glyphosate and its metabolite AMPA (aminomethylphosphonic Acid) in cereals after derivatization by isotope dilution and UPLC-MS/MS. Food Anal Methods 5:1177–1185. https://doi.org/10.1007/s12161-011-9361-7

HRAC, Herbicide Resistance Action Committee, (Accessed: 14.06.2021) http://www.hracglobal.com/

ISO 16308:2014 (2014) Water quality — determination of glyphosate and AMPA — method using high performance liquid chromatography (HPLC) with tandem mass spectrometric detection. https://www.iso.org/standard/56140.html

Jansons M, Pugajeva I, Bartkevics V, Karkee HB (2021) LC-MS/MS characterisation and determination of dansyl chloride derivatised glyphosate, aminomethylphosphonic acid (AMPA), and glufosinate in foods of plant and animal origin. J Chromatogr B 1177:122779. https://doi.org/10.1016/j.jchromb.2021.122779

Jiang Y, Cao Z, Jia R, Qi H, Chen M (2012) Determination of glyphosate and aminomethylphosphonic acid in rice using hydrophilic interaction chromatography-tandem mass spectrometry. Chin J Chromatogr 30:39–44. https://doi.org/10.3724/sp.j.1123.2011.08040

Kolakowski BM, Miller L, Murray A et al (2020) Analysis of glyphosate residues in foods from the Canadian retail markets between 2015 and 2017. J Agric Food Chem 68:5201–5211. https://doi.org/10.1021/acs.jafc.9b07819

Lane CS (2015) Rapid LC-MS/MS analysis of free amino acids in extracellular matrix. Technical note, SCIEX, Warrington UK https://sciex.com/content/dam/SCIEX/pdf/tech-notes/all/omics-Amino-Acids.pdf

Li B, Deng X, Guo D, Jin S (2007) Determination of glyphosate and aminomethylphosphonic acid residues in foods using high performance liquid chromatography-mass spectrometry/mass spectrometry. Chin J Chromatogr 25:486–490. https://doi.org/10.1016/S1872-2059(07)60017-0

Liao Y, Berthion J-M, Colet I et al (2018) Validation and application of analytical method for glyphosate and glufosinate in foods by liquid chromatography-tandem mass spectrometry. J Chromatogr A 1549:31–38. https://doi.org/10.1016/j.chroma.2018.03.036

Lopez SH, Dias J, Mol H, Kok A (2020) Selective multiresidue determination of highly polar anionic pesticides in plant-based milk, wine and beer using hydrophilic interaction liquid chromatography combined with tandem mass spectrometry. J Chromatogr A 1625:461226. https://doi.org/10.1016/j.chroma.2020.461226

Mairinger T, Hann S (2017) Implementation of data-dependent isotopologue fragmentation in 13C-based metabolic flux analysis. Anal Bioanal Chem 409:3713–3718. https://doi.org/10.1007/s00216-017-0339-1

Oulkar DP, Hingmire S, Goon A et al (2017) Optimization and validation of a residue analysis method for glyphosate, glufosinate, and their metabolites in plant matrixes by liquid chromatography with tandem mass spectrometry. J AOAC Int 100:631–639. https://doi.org/10.5740/jaoacint.17-0046

QuPPE (2019) Quick method for the analysis of numerous highly polar pesticides in food involving extraction with acidified methanol and LC-MS/MS measurement. (Accessed: 14.06.2021) https://www.eurl-pesticides.eu/userfiles/file/meth_QuPPe_AO_V3_2.pdf

Ramesh M, Raju B, Srinivas R et al (2011) Characterization of Nα-Fmoc-protected dipeptide isomers by electrospray ionization tandem mass spectrometry (ESI-MSn): effect of protecting group on fragmentation of dipeptides. Rapid Commun Mass Spectrom 25:1949–1958. https://doi.org/10.1002/rcm.5076

SANTE/12682/2019, Guidance document on analytical quality control and method validation procedures for pesticides residues analysis in food and feed, Supersedes Document No. SANTE/2017/11813. Implemented by 01/01/2020.https://ec.europa.eu/food/sites/food/files/plant/docs/pesticides_mrl_guidelines_wrkdoc_2019-12682.pdf

Schrübbers LC, Masís-Mora M, Rojas EC et al (2016) Analysis of glyphosate and aminomethylphosphonic acid in leaves from Coffea arabica using high performance liquid chromatography with quadrupole mass spectrometry detection. Talanta 146:609–620. https://doi.org/10.1016/j.talanta.2015.07.059

Steinborn A, Alder L, Michalski B et al (2016) Determination of glyphosate levels in breast milk samples from Germany by LC-MS/MS and GC-MS/MS. J Agric Food Chem 64:1414–1421. https://doi.org/10.1021/acs.jafc.5b05852

Tittlemier SA, Drul D, Lake B (2017) Evaluation of a commercially available enzyme-linked immunosorbent assay and a liquid chromatography–tandem mass spectrometric method for the analysis of glyphosate in wheat, oats, barley, malt, and lentils. Cereal Chem 94:1028–1036. https://doi.org/10.1094/CCHEM-01-17-0021-R

Tóth E, Tölgyesi Á, Bálint M, Ma X, Sharma VK (2022) Separation of fosetyl and phosphonic acid in food matrices with mixed-mode HPLC column coupled with tandem mass spectrometric detection and method application to other highly polar pesticides. J Chromatogr B 1189:123083. https://doi.org/10.1016/j.jchromb.2021.123083

Tölgyesi Á, Giri A, Bartha E et al (2018) Determination of thyreostats in urine using supported liquid extraction and mixed-mode cation-exchange solid-phase extraction: screening and confirmatory methods. J Chromatogr Sci 56:858–866. https://doi.org/10.1093/chromsci/bmy054

Vass A, Robles-Molina J, Pérez-Ortega P et al (2016) Study of different HILIC, mixed-mode, and other aqueous normal-phase approaches for the liquid chromatography/mass spectrometry-based determination of challenging polar pesticides. Anal Bioanal Chem 408:4857–4869. https://doi.org/10.1007/s00216-016-9589-6

Zhang Y, Dang Y, Lin X et al (2020) Determination of glyphosate and glufosinate in corn using multi-walled carbon nanotubes followed by ultra high performance liquid chromatography coupled with tandem mass spectrometry. J Chromatogr A 1619:460939. https://doi.org/10.1016/j.chroma.2020.460939

Funding

Open access funding provided by ELKH Centre for Agricultural Research. MD acknowledges the financial support of TKP2021-NKTA-06.

Author information

Authors and Affiliations

Contributions

Conceptualization, Ádám Tölgyesi and Mihály Dernovics; methodology, Ádám Tölgyesi, Mihály Dernovics and Tamás Farkas; formal analysis and investigation, Ádám Tölgyesi, Mihály Dernovics, Edgár Tóth and Andrea Simon; writing—original draft preparation, Ádám Tölgyesi, Mihály Dernovics and Mária Bálint

Corresponding author

Ethics declarations

Ethics Approval

This article does not contain any studies with human or animal subjects performed by any of the authors.

Consent for Publication

Publication has been approved by all individual participants.

Conflict of Interest

Ádám Tölgyesi declares that he has no conflict of interest. Edgár Tóth declares that he has no conflict of interest. Tamás Farkas declares that he has no conflict of interest. Andrea Simon declares that she has no conflict of interest. Mihály Dernovics declares that he has no conflict of interest. Mária Bálint declares that she has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tölgyesi, Á., Tóth, E., Farkas, T. et al. Determination of Aminophosphonate Herbicides in Glutamate Loaded Spice Mix by LC-IDMS and Method Extension to Other Food Matrices. Food Anal. Methods 15, 2012–2025 (2022). https://doi.org/10.1007/s12161-022-02248-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-022-02248-9