Abstract

The aim of the present study was an attempt to utilize density measurements using different methods as 3D scanning, hydrostatic, and pycnometric for the estimation of chemical composition of 20 pork semispinalis capitis. The density determined with direct (hydrostatic, pycnometric) and indirect (3D scanning) methods was correlated with water, protein, fat, and ash content. The highest correlation coefficients (absolute value) between density and water (r = 0.86), protein (r = 0.79), and fat (r = − 0.87) content of pork necks were found for hydrostatic method. Despite the standard error of prediction (SEP) obtained for density determination using 3D scanning method was close to acceptable tolerance range recommended by the EU law, which amounts to 20% mean value on the declaration of calculated fat and protein content in a product, further studies are needed on a larger population of samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Raw material standardization constitutes a very important problem of the meat industry. The control of the basic chemical component content of meat is important for technological, economical as well as legal aspect of process manufacturing. Raw material that is standardized for the basic chemical composition allows for obtaining the production repeatability (Prieto et al. 2009a; Campagnol et al. 2012; Ham et al. 2016). The role of pork meat standardization in the technological aspect will be the determination of basic chemical component content in each production lot. The lack of raw material homogeneity constitutes a serious difficulty in the processing because production processes not only do equalize, but also intensify the quality differences within the same product assortments (Campagnol et al. 2012; Ham et al. 2016).

Losses incurred by the manufacturer as a result of manufacturing products with fat level lower than assumed have economic importance, which is related to the difference in prices of lean meat and fine fat (Windham et al. 2003).

Legal importance of raw material standardization results from the need to ensure the compatibility of the finished product composition with, e.g., company standardization documents. The problem of standardization takes on particular legal significance because of the approaching deadline for the mandatory labeling of product nutritional value—starting from December 13, 2016, following European Union Regulation 1169/2011 (Regulation EU 2011). The problem is of particular importance for whole muscle products such as kesslers, sirloin steaks, hams, and bacon in which the determination of the basic chemical composition using standard methods involves sample destruction. Results of a single element examination often do not reflect the content of basic chemical components in an entire production lot (Adamczak et al. 2015). Thus, meat chemical composition should be one of the strict control elements. The standard methods of its analytical determination are time- and labor-consuming (Gaitán-Jurado et al. 2008; Prieto et al. 2009b; Wold et al. 2011). Methods based on the use of near-infrared reflectance spectroscopy (NIR) or dual X-ray (DXR) are used in practice but require acquisition of relatively expensive equipment (De Prados et al. 2015; Li et al. 2016). It may constitute a barrier for meat processing plants with small or medium production size. Therefore, there is a need for new methods that will determine chemical composition of meat relatively fast (ElMasry and Nakauchi 2015).

The literature (Adamczak et al. 2015; Nowak et al. 2016) demonstrates that chemical composition of meat (water, protein, and fat content) is strictly correlated to its density. The density determination can be performed using several methods: pycnometric, hydrostatic, and indirectly with modern method of 3D scanning, thanks to which a precise volume determination is possible, which allows for the calculation of a product density (Marcotte et al. 2008; Michailidis et al. 2009; Kelkar et al. 2011). In the publications on the use of 3D scanning in food examinations, the authors focused their attention primarily on issues of precision of product volume estimation. As an example, Uyar and Erdoğdu (2009) determined that there exists a possibility to use a 3D scanning technique for the determination of volume of food products with irregular shapes, such as bananas, pears, and eggs. Goñi et al. (2007) using 3D scanning technique determined the volume of pieces of meat. The 3D scanning method was also used for the determination of cereal product porosity, and the authors underlined the fact that using this method does not require analytic preparation of a sample (Russ 2015).

In case of the pycnometric method, its use is limited to minced meat (the measuring vessel should be accurately filled), but the 3D scanning and hydrostatic methods can be used in determining the density of the whole meat elements. The disadvantage of the hydrostatic method is the necessity to immerse the meat in a reference liquid.

The theoretical relationship between the meat density and its fat content can be calculated as follows:

-

1)

the principle of density additivity:

where

- xw, xp, xf, xa:

-

mass fractions of water, protein, fat, ash, respectively

- ρw, ρp, ρf, ρa:

-

density of water, protein, fat, ash, respectively

-

2)

the sum of mass fractions of components, equal to the unity:

-

3)

“Feder’s number” determining the amount of water (xw) to protein (xp) ratio:

The “Feder’s number,” in English-speaking countries, is sometimes referred to as “Stubbs’ and More’s number” (Feder 1913; Stubbs and More 1919; Reith et al. 1955; Kenawi et al. 2009), depends on animal species, from which meat is obtained and the element of carcass as well. This value changes for individual elements of carcass only to a slight degree. As an example, for poultry meat, this ratio remains in the range between 3.05–3.78 and the lower values characterize turkey meat. For pork meat, the xw/xb ratio ranges from 3.24 to 3.85. The mutual relationships between water and protein content were used in the EU procedures on the determination of meat content in, e.g., products from pork meat. They are also used for the determination of the amount of water absorbed by carcasses or ready-to-cut portions of chicken during post-mortem cooling (Commission Regulation 2002, 2008).

On the basis of Eqs. 1, 2, and 3 and by calculating the constant A that amounts to A = (NFe + 1) and by assuming that ash content in meat remains at the level of 1.0% after conversions, the following correlation is obtained:

Assuming low variability of NFe and the fact that ρf < ρw and ρp, the density of the system will be inversely proportional to the fat content (xf). Thus, the correlation allows to correlate the density with fat content and also indirectly with the content of the remaining chemical components (water and protein).

The aim of the present study was an attempt to utilize density measurements using different methods as 3D scanning, hydrostatic, and pycnometric for the estimation of chemical composition of pork meat (m. semispinalis capitis).

Materials and Methods

Sampling Procedure

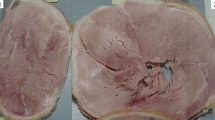

Twenty pork semispinalis capitis muscles constituted the study material. The raw material was obtained from 20 different right pork carcasses from three different slaughter days. Weight of fatteners slaughtered under industrial conditions (pigs of the Polish Large White or Polish Landrace breed crosses) ranged between 95 and 110 kg. The carcasses were cooled following the procedures of the slaughterhouse, i.e., for 24 h using two-stage cooling (1st air temperature − 10 °C, time 1–2 h, 2nd air temperature 0–4 °C, time approx. 22 h, till temperature in the thermal center of muscle not higher than 4 °C). After this time, muscle samples of approximately 1000 g each were obtained, and the raw material, which had variable intramuscular fat content (visual assessment), was selected for the study. Visual assessment was performed and low, medium, and high fat contents were selected on the cross-sections of meat samples.

First, 3D scanning of the whole pork necks was performed. After the density was determined using this method, each sample of the material was minced in a meat grinder (MESKO, Skarżysko Kamienna, Poland) with orifice diameter 2 mm and homogenized by precise mixing. Then, from this prepared material, independent meat samples were obtained to determine the density with the use of pycnometric and hydrostatic methods.

3D Scanning—Whole Meat Element Volume and Density Determination

On the basis of point clouds obtained using the ScanBright archeo 2 volume (SMARTTECH, Łomianki, Poland) scanner, the determination of density of the studied pork necks was performed. The methodology was done according to Adamczak et al. (2015). Briefly, the detector resolution was 2560 × 1920 (pix) and the test was conducted in the following scanning field 180 × 240 × 210 mm (height × depth × width). The source of light was white. The accuracy of the device was 0.03 mm (declared by the manufacturer). The scanner was equipped with a rotation table and a ball head tripod. The elements were placed on a rotation table and nine scans were captured at every 40° to obtain a complete image of it (the duration of one sample scanning process was around 180 s). Using the commercial software (Mesh3D), the artifacts in the generated images were removed. In order to facilitate the further data processing, the point cloud was dispersed using a linear algorithm whose simplification value was 2 mm. After the dispersion, the clouds contained 34.000 points. Using the Leios2 software (E.G.S., Italy), the solids were constructed and the densities (mm3) were determined based on the simplified point cloud.

Then, the weight of each pork neck was obtained to determine its density. The weight was obtained using scales with precision to 0.01 g (Axis AGZ 4000C, Axis, Gdańsk, Poland). The density was determined using the formula:

where

- ρ :

-

density (g/cm3),

- m :

-

weight (of a pork neck) (g),

- V :

-

volume determined using scanning method 3D (cm3).

Pycnometric Method—Minced Meat Density Determination

A test tube with volume 94.76 cm3 was used to obtain the pycnometric density measurements of the minced meat. The tube was exactly filled with small portions of the minced meat so that free spaces were removed. The meat was smoothed at the ends of the tube using a glass plate. Then, the test tube was weighed on an analytical scale (precision 0.0001 g, VAA 210/C/1, Radwag, Radom, Poland). Meat density was obtained by dividing the weight of a sample by the volume of the test tube, according to Eq. (5). For each meat sample, measurement was performed three times, and the results were averaged. This procedure was adopted according to Marcotte et al. (2008).

Hydrostatic Method—Minced Meat Density Determination

The measurement was conducted for three meat samples with weight of approx. 50 g obtained from each minced pork neck. The scales equipped with an attachment for the determination of density of solids using hydrostatic method were used (WPS 360/C/2, Radwag, Radom, Poland). The samples were weighed in air and then the same samples were immersed in the reference liquid (water) and their mass was also determined. Water temperature was controlled (4–6 °C) and included in the following calculations. Meat sample density was calculated according to the formula:

where

- ρ :

-

sample density at measurement temperature (g/cm3),

- A :

-

sample weight in air (g),

- B :

-

sample weight in liquid (g),

- ρ 0 :

-

reference liquid density in measurement temperature (g/cm3).

The obtained results were averaged. Samples, which were used for the determination using hydrostatic method, were not used for the determination of the basic chemical composition of the meat, due to their contact with the reference liquid. Temperature of meat during measurement did not exceed 5 °C.

Basic Chemical Composition Determination

The content of water, fat, protein, and ash in such prepared samples was determined using the appellate methods (AOAC 2000). The moisture content was determined by drying the samples at 105 °C for 3 h (SUP-65 dryer, Wamed, Warsaw, Poland). The fat content was determined by Soxhlet extraction (Büchi Extraction System B-811, Büchi, Switzerland). The protein content was determined by the Kjeldahl method (Velp Scientifica UDK 129 Distillation Unit, Poland). The ash content was determined by ashing the samples at 550 °C for 24 h in a muffle furnace (P.E.M.-2, Prodryn, Wodzisław Śląski, Poland). For each meat sample, two repetitions were made, and the results were averaged.

Statistical Analysis

Using the Statistica ver. 10 PL (StatSoft Inc. Tulsa, USA) software, the obtained results were subjected to the statistical analysis. One-way ANOVA was used to determine the differences in density evaluated by various methods. The detailed testing was conducted using Tukey’s HSD test (significance level P < 0.05). From the theory, it is known that the relationship between the density and the fat content of meat is of the character of a reciprocal function (see Eq. 4). In order to determine the empirical relationship between the density and the content of individual chemical components of meat, comparison of alternative models was made. For each method of density determination, best fit regression models were, however, different and also differentiated for protein, water, and fat content in meat. In case of the linear model, all calculated correlation coefficients between the density determined by different methods and the content of individual chemical components were statistically significant, which is why this model was chosen to be presented in this article. Relationships between the meat density obtained using 3D scanning, pycnometric, and hydrostatic method and chemical composition were determined using Pearson linear correlation. Regression equations were estimated between the water, protein, fat, and ash content and the density of the studied meat. All statistical analyses were conducted at a significance level of P < 0.05. To determine the accuracy of estimation of content of chemical components on the basis of the meat density found using different methods, the standard error of prediction (SEP) was calculated.

Results and Discussion

Raw Material Characteristic

The studied pork necks were characterized by variability of chemical composition (Table 1), e.g., fat content remained in a wide range between 9.59 and 22.91%. An obtained mean content values and medians for all chemical components indicate equal distribution of samples in the entire variability range. Mean meat densities determined using 3D scanning method and hydrostatic method amounted to 1.0410 and 1.0382 g/cm3, respectively. On the contrary, a significantly higher meat density was determined from the measurements performed using pycnometric method (Table 1). Differences in the density determined by various methods could be caused by different homogeneity as well as mincing or lack of mincing. Density values of fresh pork meat in the studies conducted by Sosa-Morales et al. (2006) ranged between 1.0823 and 1.0997 g/cm3, being very similar to those reported by Sanz et al. (1987) for pork boneless (1.090 g/cm3) and for ham (1.070 g/cm3).

The analyzed pork necks were characterized by a high variability of fat content (difference between minimum and maximum value was approx. 13% units) and the lowest for protein (approx. 5% units). The change of fat content in the meat samples in the range from minimum to maximum value caused variable changes of density depending on the used determination method (from approx. 0.03 to 0.1 g/cm3, Table 1). Compared to fat, water content in the pork necks changed to a lesser range (approx. 10% units, Table 1). The lowest variability was observed in the ash content of meat, the mean level of which was 0.92%, thus similar to the value assumed in the theoretical considerations of the present study’s topic.

Correlation Between Density and Chemical Composition of Meat

Relationships between density, measured using different methods, and the content of the basic chemical components of pork necks were determined on the basis of correlation analysis. The significance (P < 0.05) of correlation was determined between water, protein, and fat content and the densities of meat samples’ measurement by the different methods were assayed. The obtained correlation coefficients and regression equations are presented in Table 2. The highest (in the absolute value) correlation coefficients were found between fat and water content and the meat density, independent of the method used. The lowest correlation coefficient was found in the case of protein content (Table 2) and the lowest and not significant in the case of ash content (not shown).

Among the used methods of meat density determination, the hydrostatic method was characterized by the highest correlation coefficients (in the absolute value) with characteristic features of chemical composition of pork necks (Table 2). In this method, the strongest correlation was found between the meat density and the fat and water content. The relationship between the meat density, determined using hydrostatic method, and fat content is presented in Fig. 1. Dotted lines indicate confidence and prediction bands (for the level 0.95). Noteworthy is the fact of the considerable variability of equations between individual density determination methods. This indicates that in the case of an attempt at using each of these methods for the estimation of chemical composition of meat, an individual determination of regression equation should be used. In contrast to our research, Marcotte et al. (2008) found no correlation between the density of fine emulsion of bologna and wieners, coarse emulsion of pepperoni, turkey emulsion and flaky ham, and their chemical composition (water, protein, and fat content). Authors found only a correlation between the density of the emulsion and the content of carbohydrates.

On the basis of standard errors of prediction (SEP) values, the precision of water, protein, and fat content estimation on the basis of the density determined using hydrostatic method of the examined meat was 1.7, 0.7, and 2.2%, respectively. Higher SEP values were determined for pycnometric method and 3D scanning method (Table 2). It seems that the calculated accuracy of estimation can be sufficient for the correct production planning and the may be the basis for calculating the nutritional value of meat products in order to place the nutritional declaration on a label. The SEP obtained in the present study for 3D method at the level of 3.3% for mean fat content at 15.39 and 1.0% for protein content at 17.37% is close to the tolerance range recommended by the EU law, amounting to 20% of the mean value on the declaration of fat and protein content in the product (European Commission 2012). Although the 3D method was characterized by lower correlation coefficients and higher prediction error, for chemical composition estimation of the whole muscle elements, it can be possibly used under industrial conditions (it does not require a sample being trimmed/minced or immersed in reference liquid). However, the cost of this device is relatively high (approx. 50,000 €) and duration of one scanning process (depending on the resolution and the number of scans collected per one 3D image). In addition, industrial applications would require the development of software for automatic processing of acquired scans/images, because the manual scan post-processing is, for this moment, time-consuming. In the publications on the use of 3D scanning in food examinations, the authors mainly focused their attention primarily on issues of accuracy of product volume estimation. For example, Goñi et al. (2007) using 3D scanning technique determined the volume of, e.g., pieces of meat with mean estimation error lower than 2%.

Conclusions

Regardless of the used method, the pork neck density can constitute in the future basis for the estimation of its basic chemical component content. The hydrostatic and pycnometric methods, due to the ease of determination and low cost of equipment, can constitute alternatives for methods requiring more expensive devices for the determination of chemical composition of minced meat. However, despite the high correlations between density determined using hydrostatic and pycnometric methods, and the water, protein, and fat content in the studied pork necks, their use in the industrial practice may be limited. This limitation stems from the need to grind and homogenize the sample obtained from a production lot and, therefore, the methods cannot be used for the estimation of chemical composition of the whole muscle elements (ham, neck). The 3D scanning method is not characterized by such limitations, but it is relatively expensive and still time-consuming. However, further studies on a larger scale of samples are needed. Research should take into account all the fat and protein meat content range and different meat cuts to be able to define which method has more precision.

References

Adamczak L, Chmiel M, Florowski T, Pietrzak D, Witkowski M, Barczak T (2015) A potential use of 3-D scanning to evaluate the chemical composition of pork meat. J Food Sci 80(7):1506–1511. https://doi.org/10.1111/1750-3841.12913

AOAC (2000) Official methods of analysis of AOAC international, 17th edn. Gaithersburg, Association of Official Analytical Chemists

Campagnol PCB, dos Santos BA, WagnerR TNN, Pollonio MAR (2012) Amorphous cellulose gel as a fat substitute in fermented sausages. Meat Sci 90(1):36–42. https://doi.org/10.1016/j.meatsci.2011.05.026

Commission Regulation (EC) (2002) No 2004/2002 of 8 November 2002 relating to the procedure for determining the meat and fat content of certain pig meat products (OJ L 308, 9.11.2002, p. 22–24)

Commission Regulation (EC) (2008) No 543/2008 of 16 June 2008 laying down detailed rules for the application of Council regulation (EC) No 1234/2007 as regards the marketing standards for poultry meat. (OJ L 157, 17.6.2008, p. 46–87)

De Prados M, Fulladosa E, Gou P, Muñoz I, Garcia-Perez JV, Benedito J (2015) Non-destructive determination of fat content in green hams using ultrasound and X-rays. Meat Sci 104:37–43. https://doi.org/10.1016/j.meatsci.2015.01.015

ElMasry G, Nakauchi S (2015) Noninvasive sensing of thermal treatments of Japanese seafood products using imaging spectroscopy. Int J Food Sci Technol 50(9):1960–1971. https://doi.org/10.1111/ijfs.12863

European Commission (2012) Guidance document for competent authorities for the control of compliance with EU legislation on: Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers, amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004 and Council Directive 90/496/EEC of 24 September 1990 on nutrition labelling of foodstuffs and Directive 2002/46/EC of the European Parliament and of the Council of 10 June 2002 on the approximation of the laws of the Member States relating to food supplements with regard to the setting of tolerances for nutrient values declared on a label. https://ec.europa.eu/food/sites/food/files/safety/docs/labelling_nutrition-vitamins_minerals-guidance_tolerances_1212_en.pdf

Feder E (1913) Eine Grundlage zur Erkennung eines übermäßigen Wasserzusatzes zu zerkleinerten Fleischwaren. Zeitschrift für Untersuchung der Nahrungs- und Genußmittel, sowie der Gebrauchsgegenstände 25(10):577–588. https://doi.org/10.1007/BF02025638

Gaitán-Jurado AJ, Ortiz-Somovilla V, España-España F, Pérez-Aparicio J, De Pedro-Sanz EJ (2008) Quantitative analysis of pork dry-cured sausages to quality control by NIR spectroscopy. Meat Sci 78(4):391–399. https://doi.org/10.1016/j.meatsci.2007.07.005

Goñi SM, Purlis E, Salvadori VO (2007) Three-dimensional reconstruction of irregular foodstuffs. J Food Eng 82(4):536–547. https://doi.org/10.1016/j.jfoodeng.2007.03.021

Ham Y-K, Hwang K-O, Kim H-W, Song D-H, Kim Y-J, Choi Y-S, Ch-J K (2016) Effects of fat replacement with a mixture of collagen and dietary fibre on small calibre fermented sausages. Int J Food Sci Technol 51(1):96–104. https://doi.org/10.1111/ijfs.12960

Kelkar S, Stella S, Boushey C, Okos M (2011) Developing novel 3D measurement techniques and prediction method for food density determination. Proc Food Sci 1:483–491. https://doi.org/10.1016/j.profoo.2011.09.074

Kenawi MA, Abdelsalam RR, El-Sherif SA (2009) The effect of mung bean powder, and/or low fat soy flour as meat extender on the chemical, physical, and sensory quality of buffalo meat product. Biotechnol Anim Hus 25(5-6-1):327–337. https://doi.org/10.2298/BAH0906327K

Li X, Feng F, Gao R, Wang L, Qian Y, Li C, Zhou G (2016) Application of near infrared reflectance (NIR) spectroscopy to identify potential PSE meat. J Sci Food Agric 96(9):3148–3156. https://doi.org/10.1002/jsfa.7493

Marcotte M, Taherian AR, Karimi Y (2008) Thermophysical properties of processed meat and poultry products. J Food Eng 88(3):315–322. https://doi.org/10.1016/j.jfoodeng.2008.02.016

Michailidis PA, Krokida MK, Bisharat GI, Marinos-Kouris D, Rahman MS (2009) Measurement of density, shrinkage and porosity. In: Rahman MS (ed) Food properties handbook. CRC Press Taylor &Francis Group, Boca Raton, pp 397–416

Nowak KW, Markowski M, Daszkiewicz T (2016) A modified ultrasonic method for determining the chemical composition of meat products. J Food Eng 180:10–15. https://doi.org/10.1016/j.jfoodeng.2016.02.010

Prieto N, Roehe R, Lavín P, Batten G, Andrés S (2009a) Application of near infrared reflectance spectroscopy to predict meat and meat products quality: a review. Meat Sci 83(2):175–186. https://doi.org/10.1016/j.meatsci.2009.04.016

Prieto N, Ross DW, Navajas EA, Nute GR, Richardson RI, Hyslop JJ, Simm G, Roehe R (2009b) On-line application of visible and near-infrared reflectance spectroscopy to predict chemical, physical and sensory characteristics of beef quality. Meat Sci 83(1):96–103. https://doi.org/10.1016/j.meatsci.2009.04.005

Regulation (EU) (2011) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers, amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004 (OJ L 304, 22.11.2011, p. 18–63)

Reith JF, Hofsteede MJN, Langbroek W (1955) The nitrogen content of meat and the calculation of the meat content of meat products. J Sci Food Agric 6(6):317–323. https://doi.org/10.1002/jsfa.2740060605

Russ JC (2015) Image analysis of foods. J Food Sci 80(9):1974–1987. https://doi.org/10.1111/1750-3841.12987

Sanz PD, Alonso MD, Mascheroni RH (1987) Thermophysical properties of meat products: general bibliography and experimental values. Trans ASAE 30(1):0283–0290. https://doi.org/10.13031/2013.30441

Sosa-Morales ME, Orzuna-Espíritu R, Vélez-Ruiz JF (2006) Mass, thermal and quality aspects of deep-fat frying of pork meat. J Food Eng 77(3):731–738. https://doi.org/10.1016/j.jfoodeng.2005.07.033

Stubbs G, More A (1919) The estimation of the appropriate quantity of meat in sausages and meat pastes. Analyst 44(517):125–127. https://doi.org/10.1039/AN9194400125

Uyar R, Erdoğdu F (2009) Potential use of 3-dimensional scanners for food process modeling. J Food Eng 93(3):337–343. https://doi.org/10.1016/j.jfoodeng.2009.01.034

Windham WR, Lawrence KC, Feldner PW (2003) Prediction of fat content in poultry meat by near-infrared transmission analysis. J Appl Poult Res 12(1):69–73. https://doi.org/10.1093/japr/12.1.69

Wold JP, O’Farrell M, Høy M, Tschudi J (2011) On-line determination and control of fat content in batches of beef trimmings by NIR imaging spectroscopy. Meat Sci 89(3):317–324. https://doi.org/10.1016/j.meatsci.2011.05.001

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Marta Chmiel declares that she has no conflict of interest. Lech Adamczak declares that he has no conflict of interest. Tomasz Florowski declares that he has no conflict of interest. Dorota Pietrzak declares that she has no conflict of interest. Marcin Witkowski declares that he has no conflict of interest. Tomasz Barczak declares that he has no conflict of interest.

Ethical Approval

All applicable international, national, and/or institutional guidelines for the care and use of animals were followed.

Informed Consent

Not applicable.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Adamczak, L., Chmiel, M., Florowski, T. et al. Using Density Measurement on Semispinalis capitis as a Tool to Determinate the Composition of Pork Meat. Food Anal. Methods 11, 1728–1734 (2018). https://doi.org/10.1007/s12161-018-1151-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-018-1151-z