Abstract

The development of novel and sustainable bioprocesses for the valorization of agri-food by-products is required for the food industry to transition to a circular economy. The objective of this study to evaluate a sequential process consisting of fed-batch pretreatment followed by semi-continuous anaerobic digestion of brewer’s spent grains for the production of biomethane and bioenergy. Anaerobic digestion was conducted under mesophilic and methanogenic conditions, and the digestate and corresponding biogas were characterized to determine the process efficiency. Experimental results indicate that the fed-batch pretreatment improves the biogas production obtained from the semi-continuous process. The methane yield during the fed-batch pretreatment was 11.89 L CH4/kg TVSadded, while in the semi-continuous process, the yield was 30.61 L CH4/kg TVSadded. The biogas produced in the semi-continuous process could generate electricity (66.9 kWh/t) and heat (316.75 MJ/t), avoiding greenhouse gas emissions (20.81 kg CO2eq/t). Implementing the novel anaerobic digestion system could be a promising approach for the valorization of brewery by-products, producing renewable energy from biomass.

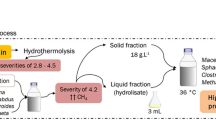

Graphical Abstract

Similar content being viewed by others

References

NunesFerraz Junior AD, Etchebehere C, Perecin D et al (2022) Advancing anaerobic digestion of sugarcane vinasse: current development, struggles and future trends on production and end-uses of biogas in Brazil. Renew Sust Energ Rev 157:112045. https://doi.org/10.1016/J.RSER.2021.112045

Khazaai SNM, Bhuyar P, Strezov V et al (2023) Optimization of rubber seed oil extraction: adaptive neuro-fuzzy inference-based yield prediction model by studying polarity and moisture content. Bioenergy Res 1:1–11. https://doi.org/10.1007/S12155-023-10635-1/FIGURES/6

Trejo M, Bhuyar P, Velu G et al (2022) The effect of various pretreatments conditions on the distribution of fermentable sugar from dried elephant ear plant. Fuel 324:124624. https://doi.org/10.1016/J.FUEL.2022.124624

Vögeli Y, Lohri CR, Gallardo A, Diener S, Zurbrügg C (2014) Anaerobic digestion of biowaste in developing countries: practical information and case studies. Swiss Federal Institute of Aquatic Science and Technology (Eawag), Dübendorf, Switzerland, pp 1–134

Chen Y, Pinegar L, Immonen J, Powell KM (2023) Conversion of food waste to renewable energy: a techno-economic and environmental assessment. J Clean Prod 385:135741. https://doi.org/10.1016/J.JCLEPRO.2022.135741

da Rosa RG, Sganzerla WG, Barroso TLCT et al (2023) Sustainable bioprocess combining subcritical water pretreatment followed by anaerobic digestion for the valorization of jabuticaba (Myrciaria cauliflora) agro-industrial by-product in bioenergy and biofertilizer. Fuel 334:126698. https://doi.org/10.1016/J.FUEL.2022.126698

Sganzerla WG, Ampese LC, Mussatto SI, Forster-Carneiro T (2021) A bibliometric analysis on potential uses of brewer’s spent grains in a biorefinery for the circular economy transition of the beer industry. Biofuels, Bioprod Bioref 15:1965–1988. https://doi.org/10.1002/BBB.2290

Pellera FM, Gidarakos E (2017) Microwave pretreatment of lignocellulosic agroindustrial waste for methane production. J Environ Chem Eng 5:352–365. https://doi.org/10.1016/J.JECE.2016.12.009

Mohammad Rahmani A, Gahlot P, Moustakas K et al (2022) Pretreatment methods to enhance solubilization and anaerobic biodegradability of lignocellulosic biomass (wheat straw): progress and challenges. Fuel 319:123726. https://doi.org/10.1016/J.FUEL.2022.123726

Passos F, Carretero J, Ferrer I (2015) Comparing pretreatment methods for improving microalgae anaerobic digestion: thermal, hydrothermal, microwave and ultrasound. Chem Eng J 279:667–672. https://doi.org/10.1016/J.CEJ.2015.05.065

González-Fernández C, Sialve B, Bernet N, Steyer JP (2012) Comparison of ultrasound and thermal pretreatment of Scenedesmus biomass on methane production. Bioresour Technol 110:610–616. https://doi.org/10.1016/J.BIORTECH.2012.01.043

Raut MP, Pandhal J, Wright PC (2021) Effective pretreatment of lignocellulosic co-substrates using barley straw-adapted microbial consortia to enhanced biomethanation by anaerobic digestion. Bioresour Technol 321:124437. https://doi.org/10.1016/J.BIORTECH.2020.124437

Wang L, Feng J, Cai F et al (2021) Anaerobic digestion and lignocellulosic compositions alteration of industrial vinegar residue after different pretreatments. Environ Technol Innov 24:101941. https://doi.org/10.1016/J.ETI.2021.101941

Berglund M, Börjesson P (2006) Assessment of energy performance in the life-cycle of biogas production. Biomass Bioenerg 30:254–266. https://doi.org/10.1016/J.BIOMBIOE.2005.11.011

Ampese LC, Sganzerla WG, Di Domenico ZH et al (2022) Research progress, trends, and updates on anaerobic digestion technology: a bibliometric analysis. J Clean Prod 331:130004. https://doi.org/10.1016/J.JCLEPRO.2021.130004

Sganzerla WG, Tena M, Sillero L et al (2023) Application of anaerobic co-digestion of brewery by-products for biomethane and bioenergy production in a biorefinery concept. Bioenergy Res 1:1–14. https://doi.org/10.1007/S12155-023-10605-7/FIGURES/4

Sganzerla WG, Sillero L, Forster-Carneiro T et al (2022) Determination of anaerobic co-fermentation of brewery wastewater and brewer’s spent grains for bio-hydrogen production. Bioenergy Res 16:1073–1083. https://doi.org/10.1007/S12155-022-10486-2/FIGURES/4

Buller LS, Sganzerla WG, Lima MN et al (2022) Ultrasonic pretreatment of brewers’ spent grains for anaerobic digestion: biogas production for a sustainable industrial development. J Clean Prod 355:131802. https://doi.org/10.1016/J.JCLEPRO.2022.131802

Sganzerla WG, Ampese LC, Mussatto SI, Forster-Carneiro T (2022) Subcritical water pretreatment enhanced methane-rich biogas production from the anaerobic digestion of brewer’s spent grains. Environ Technol 1–19

Ponnusamy S, Reddy HK, Muppaneni T et al (2014) Life cycle assessment of biodiesel production from algal bio-crude oils extracted under subcritical water conditions. Bioresour Technol 170:454–461. https://doi.org/10.1016/J.BIORTECH.2014.07.072

Sganzerla WG, Viganó J, Castro LEN et al (2022) Recovery of sugars and amino acids from brewers’ spent grains using subcritical water hydrolysis in a single and two sequential semi-continuous flow-through reactors. Food Res Int 157:111470. https://doi.org/10.1016/J.FOODRES.2022.111470

Sganzerla WG, Costa JM, Tena-Villares M et al (2022) Dry anaerobic digestion of brewer spent grains toward a more sustainable brewery: operational performance, kinetic analysis, and bioenergy potential. Ferment 2023 9:2. https://doi.org/10.3390/FERMENTATION9010002

Jadhav P, Bin KZ, Krishnan S et al (2022) Application of iron-cobalt-copper (Fe-Co–Cu) trimetallic nanoparticles on anaerobic digestion (AD) for biogas production. Biomass Convers Biorefinery 1:1–11. https://doi.org/10.1007/S13399-022-02825-2/TABLES/2

Jadhav P, Nasrullah M, Zularisam AW et al (2021) (2021) Direct interspecies electron transfer performance through nanoparticles (NPs) for biogas production in the anaerobic digestion process. Int J Environ Sci Technol 1910(19):10427–10439. https://doi.org/10.1007/S13762-021-03664-W

Baird R, Rice E, Eaton A (2017) Standard methods for the examination of water and wastewaters. Water Environment Federation, Chair Eugene W. Rice, American Public Health Association Andrew D. Eaton, American Water Works Association

Campello LD, Barros RM, Tiago Filho GL, dos Santos IFS (2021) Analysis of the economic viability of the use of biogas produced in wastewater treatment plants to generate electrical energy. Environ Dev Sustain 23:2614–2629. https://doi.org/10.1007/s10668-020-00689-y

Chernicharo CDL, Bressani-Ribeiro T, Pegorini ES, Possetti GRC, Miki MK, Souza SN (2018) Contribution for improvingthe design, construction and operation of UASB reactors treating sewage–part 1: topics of Interest (Contribuição para o aprimoramento de projeto, construção e operação de reatores UASB aplicados ao tratamento de esgoto sanitário–Parte 1: Tópicos de Interesse). Revista DAE 66:5–16

dos Santos MA, Damázio JM, Rogério JP et al (2017) Estimates of GHG emissions by hydroelectric reservoirs: the Brazilian case. Energy 133:99–107. https://doi.org/10.1016/J.ENERGY.2017.05.082

Gonde L, Wickham T, Brink HG, Nicol W (2023) pH-based control of anaerobic digestion to maximise ammonium production in liquid digestate. Water 15:417. https://doi.org/10.3390/W15030417

Kothari R, Pandey AK, Kumar S et al (2014) Different aspects of dry anaerobic digestion for bio-energy: an overview. Renew Sustain Energy Rev 39:174–195. https://doi.org/10.1016/J.RSER.2014.07.011

Baldi F, Pecorini I, Iannelli R (2019) Comparison of single-stage and two-stage anaerobic co-digestion of food waste and activated sludge for hydrogen and methane production. Renew Energy 143:1755–1765. https://doi.org/10.1016/J.RENENE.2019.05.122

Issah AA, Kabera T (2021) Impact of volatile fatty acids to alkalinity ratio and volatile solids on biogas production under thermophilic conditions. Waste Manag Res 39:871–878. https://doi.org/10.1177/0734242X20957395

Li L, Feng L, Zhang R et al (2015) Anaerobic digestion performance of vinegar residue in continuously stirred tank reactor. Bioresour Technol 186:338–342. https://doi.org/10.1016/J.BIORTECH.2015.03.086

Sun H, Wu S, Dong R (2016) Monitoring volatile fatty acids and carbonate alkalinity in anaerobic digestion: titration methodologies. Chem Eng Technol 39:599–610. https://doi.org/10.1002/CEAT.201500293

Chen S, Zhang J, Wang X (2015) Effects of alkalinity sources on the stability of anaerobic digestion from food waste. Waste Manag Res 33:1033–1040. https://doi.org/10.1177/0734242X15602965

Yenigün O, Demirel B (2013) Ammonia inhibition in anaerobic digestion: a review. Process Biochem 48:901–911. https://doi.org/10.1016/j.procbio.2013.04.012

Zhu G, Peng Y, Wang S et al (2007) Effect of influent flow rate distribution on the performance of step-feed biological nitrogen removal process. Chem Eng J 131:319–328. https://doi.org/10.1016/J.CEJ.2006.12.023

Duan W, Gunes M, Baldi A et al (2022) Compact fluidic electrochemical sensor platform for on-line monitoring of chemical oxygen demand in urban wastewater. Chem Eng J 449:137837. https://doi.org/10.1016/J.CEJ.2022.137837

Jiménez-Castro MP, Buller LS, Zoffreo A et al (2020) Two-stage anaerobic digestion of orange peel without pre-treatment: experimental evaluation and application to São Paulo state. J Environ Chem Eng 8:104035. https://doi.org/10.1016/J.JECE.2020.104035

Weiland P (2010) Biogas production: Current state and perspectives. Appl Microbiol Biotechnol 85:849–860. https://doi.org/10.1007/S00253-009-2246-7/FIGURES/4

Vitanza R, Cortesi A, Gallo V et al (2016) Biovalorization of brewery waste by applying anaerobic digestion. Chem Biochem Eng Q 30:351–357. https://doi.org/10.15255/CABEQ.2015.2237

Sganzerla WG, Ampese LC, Parisoto TAC, Forster-Carneiro T (2021) Process intensification for the recovery of methane-rich biogas from dry anaerobic digestion of açaí seeds. Biomass Convers Biorefinery 1:1–14. https://doi.org/10.1007/S13399-021-01698-1/FIGURES/5

Abatzoglou N, Boivin S (2009) A review of biogas purification processes. Biofuels, Bioprod Biorefining 3:42–71. https://doi.org/10.1002/BBB.117

Sganzerla WG, Tena-Villares M, Buller LS et al (2022) Dry anaerobic digestion of food industry by-products and bioenergy recovery: a perspective to promote the circular economy transition. Waste Biomass Valorization. https://doi.org/10.1007/s12649-022-01682-4

Mistretta M, Gulotta TM, Caputo P, Cellura M (2022) Bioenergy from anaerobic digestion plants: energy and environmental assessment of a wide sample of Italian plants. Sci Total Environ 843:157012. https://doi.org/10.1016/J.SCITOTENV.2022.157012

Messineo A, Maniscalco MP, Volpe R (2020) Biomethane recovery from olive mill residues through anaerobic digestion: a review of the state of the art technology. Sci Total Environ 703:135508. https://doi.org/10.1016/J.SCITOTENV.2019.135508

Silwadi M, Mousa H, Al-Hajji BY, Al-Wahaibi SS, Al-Harrasi ZZ (2023) Enhancing biogas production by anaerobic digestion of animal manure. Int J Green Energy 20(3):257–264

Ugwu SN, Harding K, Enweremadu CC (2022) Comparative life cycle assessment of enhanced anaerobic digestion of agro-industrial waste for biogas production. J Clean Prod 345:131178. https://doi.org/10.1016/J.JCLEPRO.2022.131178

Acknowledgements

Katherine Vaz Gomes completed this work as part of her Major Qualifying Project at WPI.

Funding

This work was supported by the Brazilian Science and Research Foundation (CNPq) (productivity grants 302451/2021–8); Coordination for the Improvement of Higher Education Personnel (CAPES, Brazil) (Finance code 001); and São Paulo Research Foundation (FAPESP, Brazil) (grant numbers 2018/14938–4 for TFC, 2019/26925–7 for WGS, 2020/10323–5 for LSB).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

da Rosa, R.G., Sganzerla, W.G., Buller, L.S. et al. Sustainable Bioprocess Combining Fed-Batch Pretreatment Followed by Semi-Continuous Anaerobic Digestion of Brewer’s Spent Grains for Biomethane Production. Bioenerg. Res. 17, 690–699 (2024). https://doi.org/10.1007/s12155-023-10666-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-023-10666-8