Abstract

Spatial variability in yields and greenhouse gas emissions from soils has been identified as a key source of variability in life cycle assessments (LCAs) of agricultural products such as cellulosic ethanol. This study aims to conduct an LCA of cellulosic ethanol production from switchgrass in a way that captures this spatial variability and tests results for sensitivity to using spatially averaged results. The Environment Policy Integrated Climate (EPIC) model was used to calculate switchgrass yields, greenhouse gas (GHG) emissions, and nitrogen and phosphorus emissions from crop production in southern Wisconsin and Michigan at the watershed scale. These data were combined with cellulosic ethanol production data via ammonia fiber expansion and dilute acid pretreatment methods and region-specific electricity production data into an LCA model of eight ethanol production scenarios. Standard deviations from the spatial mean yields and soil emissions were used to test the sensitivity of net energy ratio, global warming potential intensity, and eutrophication and acidification potential metrics to spatial variability. Substantial variation in the eutrophication potential was also observed when nitrogen and phosphorus emissions from soils were varied. This work illustrates the need for spatially explicit agricultural production data in the LCA of biofuels and other agricultural products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The corn grain ethanol biofuel sector is well established in the USA, and many studies have evaluated some basic sustainability measures of first-generation ethanol production [1–7]. Studies of corn grain ethanol have also been verified with data from existing full-scale production facilities [4, 6]. Sustainability metrics for second-generation biofuel production such as cellulosic ethanol have not been as widely studied, and there are no commercial-scale cellulosic ethanol plants in operation for which modeling assumptions can be verified.

Life cycle assessment (LCA) is a widely accepted methodology for assessing the environmental impact of a product, as it relies on a comprehensive characterization of the production system under consideration. The lack of actual production data on biomass and cellulosic ethanol production makes conducting an LCA of cellulosic ethanol difficult. LCAs of corn grain ethanol have identified aspects of feedstock production and bio-refining with potentially negative environmental consequences and illuminated areas for improvement [1, 2, 6, 8]. Similar studies can help to reduce negative environmental consequences and improve sustainability of eventual cellulosic ethanol production systems.

A significant portion of the overall environmental benefits (such as GHG emissions reduction) and detriments (such as eutrophication and acidification) of cellulosic ethanol production stems from biomass feedstock production [3, 9–12]. The type of crop grown and the specific means of production for that crop (e.g., tillage type, fertilizer and pesticide application, harvest method, and frequency) can greatly alter the results of a full cellulosic ethanol production LCA. Furthermore, these impacts vary significantly over space and time, yet many LCA studies treat crop production as static and use spatially average inputs to ethanol production over large areas [3, 13–15]. The production of crops has more inherent uncertainty than the production of industrial goods due to the considerable variability of ecological systems over space (e.g., different soil types) and time (e.g., changes in weather patterns). Spatial variability has been identified as a key source of variability in LCAs of agricultural systems [16–18].

Site-generic LCAs lack spatial information and assume globally homogeneous effects [19]. The use of spatially homogeneous data does not invalidate a study but does limit the applicability of such a study to other regions (or even the same region under different weather conditions). In reality, the variability in agricultural production from state to state and even county to county is considerable. Models using spatially explicit datasets (e.g., Zhang et al. [20]) can improve the estimates of the environmental impacts of production systems in specific agricultural contexts.

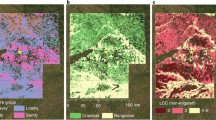

Reap et al. [18] also identify LCA problems related to space as defined by spatial variation and local environmental uniqueness. The authors define spatial variation as “differences in geology, topography, land cover (both natural and anthropogenic), and meteorological conditions,” while local environmental uniqueness is defined as “differences in the parameters describing a particular place (i.e., soil pH)”. Data to inform these parameters is usually collected along political boundaries such as county or state lines. Political boundaries, however, rarely align with the ecological distinctions in the geology, topography, and meteorology of a landscape (Fig. 1). Instead, these landscape variables, plus variables like soil type, are more likely to conform to ecological boundaries such as watersheds. To help address this problem, Potting and Hauschild [19] developed spatial treatment classifications specifically for the LCA of agricultural products.

While crop yield data may be available on a county or state level, these political geographic boundaries are incongruent with the boundaries around ecological determinants of crop production (e.g., soil type). A county line can encompass many watersheds, soil types, and microclimates. Moreover, local environmental uniqueness, such as soil pH or buffering capacity, not only affects factors like yields, but also the overall impact of an activity on the acidification of soil or water. From an ethanol refining perspective, the area of a watershed roughly corresponds to the fuel shed area from which biomass feedstock would be harvested and transported to a cellulosic ethanol plant. All of these factors point to the need for spatially explicit crop production data in the LCA of agronomic crops such as switchgrass (Panicum virgatum L.) for cellulosic ethanol production.

While there have been studies which give the agricultural production system a more dynamic treatment, these studies still treat the ethanol production step as one static conversion rate of biomass to ethanol [10, 20]. There are many variables which determine the life cycle impacts from ethanol production such as the type of biomass and the pretreatment method. Each type of biomass has a different concentration of cellulose, hemicelluloses, lignin, and ash per unit mass. Each pretreatment method produces varying amounts of hydrolysable cellulose and hemicelluloses and has the potential to produce inhibitors that reduce the overall efficiency of fermentation [21]. All of these variables affect the net yield of ethanol and, thus, the potential net energy yield, and they affect the overall LCA by determining the set of inputs to ethanol production. For example, dilute acid (DA) pretreatment requires an input of sulfuric acid, while ammonia fiber expansion (AFEX) pretreatment requires an input of ammonia and an ammonia recovery process [14, 22]. A recent study noted that, though the physical mass of inputs like enzymes and chemicals is small compared to the mass of feedstock input into the system, the production of these materials is significant to the overall ethanol LCA [23]. These types of factors provide for a more flexible and accurate accounting of the full LCA of cellulosic ethanol production. Without an operational plant to study, however, accounting for all of these production variables becomes a difficult task, which is why this has been identified as one of the “grand challenges” facing the LCA of biofuels [17].

Many biofuel studies have also noted that environmental impact factors, such as acidification and eutrophication potential, need to be evaluated in addition to the most commonly evaluated factors (net energy and GHG emissions) [8, 9, 24–26]. Agricultural system parameters (e.g., nitrogen and phosphorus application) and electricity production assumptions (e.g., the proportion of electricity generated from coal combustion which releases NOx and SOx emissions versus nuclear power which does not) will influence the overall acidification and eutrophication potential of cellulosic ethanol production. These parameters, however, change with location, so efforts must be made to source and use location-specific data for these inputs.

The main objective of this study is to perform a spatially explicit LCA on cellulosic ethanol production and obtain the net energy, global warming potential (GWP), eutrophication potential (EP), and acidification potential (AP) of this production by ammonia fiber expansion (AFEX) and dilute acid (DA) pretreatment from switchgrass under different agricultural production scenarios in southern Wisconsin and Michigan. A secondary objective of this research is to quantify the effects of crop production spatial variability and other production variables on the environmental impact assessment and the ability of switchgrass ethanol to qualify as a cellulosic biofuel.

Methods

We performed a cradle-to-gate LCA of switchgrass (SG) cellulosic ethanol production. At the time of this writing, there are no operational commercial-scale cellulosic ethanol plants in the USA; thus, there is no current demand for feedstock production. Therefore, we assumed the occurrence of a pulse in the market that would lead to the rapid construction of two cellulosic ethanol plants (in southern WI and MI), which, in turn, spur direct land use change on area occupied by field crops (e.g., corn (Zea mays) and soybean (Glycine max L. Merr.). Thus, our analysis evaluates the life cycle implications of the birth of the commercial cellulosic ethanol market in the near future.

This LCA focused on biomass and ethanol production in specific regions of southern Wisconsin (WI) and southern Michigan (MI). Life cycle inventory (LCI) data were collected for crop and ethanol production processes. Then, these data were used to develop LCA models of eight production scenarios using version 4.4 of GaBi product sustainability software [27]. The scenarios varied by nitrogen application rate (high nitrogen = 90 kg N ha−1 and medium nitrogen = 60 kg N ha−1), location (WI and MI), and pretreatment method (AFEX and DA). Finally, a sensitivity analysis was conducted to investigate the magnitude of the effect of spatial variability on the impact category metrics. All key LCA components are summarized in Table 1. This LCA was conducted as per the guidelines set forth in the ISO standards [28, 29].

The functional unit for this analysis is one unit of energy (MJ) from the final ethanol fuel (low heating value (LHV)). This unit was selected because it allows for direct comparison with other transportation fuels, coproduct energy credits, and internal comparisons between the energy yield from ethanol and the initial energy inputs from feedstocks. The LHV of SG was assumed to be 16.9 MJ (kg SG dry matter)−1 [14].

The system boundary for this analysis begins with the upstream production of agricultural inputs and ends at the biorefinery gate with fuel-grade ethanol (Fig. 2). Agricultural inputs include the following: nitrogen and potassium fertilizer and agricultural lime (soil amendments), electrical energy, petroleum fuels, and seed. Field practices include all of the activities that take place in the farm field from tillage, seed bed preparation, seeding and hoeing to pesticide and fertilizer application and harvest. Ethanol production inputs include the following: biomass, petroleum fuels, electrical energy, chemicals, and enzymes.

Process flow and system boundary diagram for feedstock production and cellulosic ethanol production. Solid lines are material flows, dashed lines are internal biorefinery heat and power flows, rectangles are stationary unit processes, rhombuses are mobile unit processes that depend on distance or area, and octagons are products

The geographic scope of this LCA focuses on two regionally intensive modeling areas (RIMAs). One is a nine-county region in southern Michigan which has been divided into 39 watersheds as they are identified by their unique ten-digit hydrologic unit code (HUC) (Fig. 1). The second region is composed of four counties in southern Wisconsin and includes 46 watersheds also identified by their unique HUC (Fig. 1). The geographic scope of the production of the agricultural inputs to the field operation is limited to US standard production assumptions. The time unit of the analysis is one annual average year of agricultural and refinery production in the near future. Crop production was modeled over 12 years, and the average yields and emissions from these 12 years were used. Twelve years was selected because SG was assumed to be grown in 12-year cycles with 2 years for establishment and 10 years of productivity before replanting. The land area currently used for crop production in the two RIMAs (WI = 211,026 ha and MI = 429,632 ha) was used for modeling SG production for this study.

Data Sources and Assumptions

Biomass yield and emissions from soils (to air and water) were modeled with the Environment Policy Integrated Climate (EPIC) model for the two RIMAs. These data were modeled at a 56 m × 56 m (0.31 ha) resolution with simulations running for 24 years with historical weather data and soil data from the USDA soil survey geographic database [30]. The specific methodology and input data sources for this biophysical and biogeochemical modeling can be found in study by Zhang et al. [20], and validation of the EPIC methods with site-specific data can be found in studies by He et al. [31], Izaurralde et al. [32], Izaurralde, et al. [33], and Wang et al. [34]. Two nitrogen application scenarios were examined: 90 kg N ha−1 for the high nitrogen (HN) and 60 kg N ha−1 for the medium nitrogen (MN) scenarios. The potassium application rate was assumed to be 34 kg K ha−1 for all scenarios. Liming rates were calculated based on crop requirements and soil pH. Crop production data from EPIC were averaged over each watershed, and the within-watershed standard deviations (SD) were calculated.

The LCI data for the upstream production of inputs to the agricultural system were sourced in GaBi 4 [27] which included the US LCI dataset produced by the National Renewable Energy Laboratory [35], the PE International Professional database [27], and the EcoInvent database [36].

Regionally specific electricity production and associated emission factors were developed using the MyPower electricity sector model [37] using data from the US EPA National Electric Energy Data System (NEEDS) [38] and assumptions based on US EPA’s Integrated Planning Model documentation [39]. Regional emission factors for transportation and process-heating fuels were based on the Greenhouse gases, Regulated Emissions, and Energy use in Transportation (GREET) model [40]. Transportation distances were calculated based on the average distance from any point in a circle to the center of a circle (two thirds the radius) for circles with the same area as the RIMAs [41] (for a full list of LCI inputs and data sources, see Supplemental Table 1). The GaBi v. 4.4 model was used as the platform to integrate data from these sources and test the sensitivity of the analysis to variations in parameters [27].

Pretreatment method specifications are not dependent on spatial location, but the inclusion of some pretreatment is necessary to complete the cradle-to-gate cellulosic ethanol production system. In the absence of a cellulosic ethanol industry with a standard pretreatment method, DA and AFEX were chosen for this study as two possible and likely methods appealing to a commercial-scale plant. The DA pretreatment specifications for heat, power, chemical inputs, and water use as well as the conversion efficiencies from biomass to relevant components were sourced from the 2011 NREL ethanol production process design study [22]. The AFEX pretreatment inputs were obtained from Great Lakes Bioenergy Research Center (GLBRC) scientists (B. Bals, personal communication, 2011) and [14] Potting and Hauschild. Separate enzymatic hydrolysis and fermentation (with recombinant Zymomonas mobilis) as well as wastewater treatment, distillation, dehydration, denaturation, and lignin combustion for process power processes are modeled after [22]. The conversion efficiencies for hexoses and pentoses to ethanol are 90 and 80 %, respectively, for DA and 95 and 95 %, respectively, for AFEX [14, 22] representing values considered attainable at commercial-scale refineries in the near term.

As mentioned, this analysis assumed a pulse in the cellulosic ethanol feedstock market with accompanying land use change implications. To account for the direct land use change (DLUC) which would result from this pulse, all emissions from agricultural lands were calculated as a change from a baseline agricultural scenario of a conventional corn–soybean rotation with high fertilizer N (155 kg N ha−1 for WI and 135 kg N ha−1 for MI), conventional chisel tillage, no stover removal, 1 kg AI ha−1 pesticide application, and phosphorus and potassium application rates of 30 kg P ha−1 and 20 kg K ha−1 for WI and 24 kg P ha−1 and 34 kg K ha−1 for MI. It was assumed that existing agricultural land in a baseline crop production system was converted to SG production. It has been noted that these sorts of DLUC effects vary substantially in the landscape and sophisticated biological models should be used to account for these changes [42]. Accounting methods for indirect land use change (ILUC) were considered outside of the goal and scope of this study because a clear and commonly accepted method for calculating ILUC is still a matter of great scientific debate [43–49].

The importance of tracking biotic versus abiotic carbon has also been noted in bioenergy literature [50]. Ecosystem carbon gains and losses (i.e., net carbon fixed from air, microbial respiration) were modeled with EPIC [33, 51]. We also accounted for the emissions of biotic CO2 in the ethanol production system (from fermentation and lignin and biogas combustion). The final product leaving the system boundary is ethanol which contains carbon that was fixed in the SG. Since combustion is not in the system boundary, this carbon is not part of the biotic carbon release. Net GHG emission values therefore account for fossil and biotic emissions and any net absorption of carbon in the system. The global warming potential (GWP), eutrophication potential (EP), and acidification potential (AP) impact category metrics are characterized measurements as per the CML 2001 characterization factors available in GaBi 4.4.

Allocation

Electricity generated from coproduct lignin combustion at the ethanol refinery displaced the use of conventional electricity generated in each RIMA at the refinery. Excess electricity was exported to the grid to displace electricity production from conventional sources specific to each region.

Sensitivity Analysis

The EPIC model outputs were aggregated by watershed with SG-production-weighted averages as well as the maximum, minimum, and SD of each output calculated for each watershed. A sensitivity analysis was conducted to estimate the variability in the final environmental impact indicators due to spatial variability.

Results

Under four production scenarios, the net energy ratio (NER), global warming potential (GWP), eutrophication potential (EP), and acidification potential (AP) for each watershed in the two RIMAs were calculated. Results for SG production are shown in Table 2 and for ethanol production (both AFEX and DA methods) in Table 3. Table 2 and Fig. 3a–d show the RIMA average values as well as the intra-RIMA variation in the impact category metrics for the four SG production scenarios. The average values represent the SG-production-weighted averages across all watersheds in each respective RIMA. The minimum and maximum represent the SG-production-weighted average values for individual watersheds within each RIMA. The coefficient of variation (COV) is calculated as the SD of within-RIMA watershed average values divided by the RIMA average value. The results of the ethanol production LCAs are given in Table 3, and the results of our sensitivity analysis for NER, GWP, AP, and EP are presented in Figs. 4, 5, 6 and 7, respectively. The ranges of values observed in the crop production LCA indicate that there is variation in all metrics across the watersheds due to differences in soils and weather, and this impacts biomass yields and emissions to soil and water.

GWP intensity (g CO2 eq MJ−1) with contributions of each GHG type and net GWP with error introduced by spatial variability in CO2 and N2O emissions from soils and yield. Abiotic CO2 emissions—the net of all fossil emissions and the absorption of CO2 by switchgrass plus the displacement of emissions from electricity production at ethanol plant. Biotic CO2 emissions—the net emission or absorption of CO2 from soils in switchgrass production plus the emission of CO2 which was originally absorbed by the switchgrass and then emitted during the production of ethanol during all of the refining steps. Sum other—SF6, VOCs, and emissions from water bodies

Discussion

SG Production

The spatial variability in SG production is considerable for some environmental impact indicators but negligible for others, with watersheds in the WI RIMA generally demonstrating more variability than those in the MI RIMA. The range of average watershed NER values (19.3 to 46.3) shows significant energy returns for SG production, and the range of average watershed GWP values (−1.85 to −0.57 kg CO2 eq kg−1) indicates improved climate outcomes across the two RIMAs (Table 2). EP expresses the most variability with average watershed values ranging from negative (−3.45 g PO4 eq kg−1) to positive (0.68 g PO4 eq kg−1), though values for both nitrogen scenarios in the MI RIMA are quite consistent. The major differences in eutrophication rates between the two RIMAs arise from the fundamental differences in soil properties. Soils in the Wisconsin RIMA are mainly Mollisols, while soils in Michigan RIMA are mainly Alfisols. Mollisols are rich in organic matter, especially in the upper soil horizons. In contrast with Alfisols, Mollisols are well buffered; have good amounts of bases (e.g., calcium and magnesium); and contain higher levels of nitrogen, phosphorus, and sulfur in the organic fraction. Additionally, the textural differences between the soils in the two RIMAs explain differences in EP. Increased nitrogen input appears to have a slight negative impact for most metrics in the two RIMAs. These results also illustrate the magnitude of error introduced by using county, state, regional, or national average values for inputs and outputs of biomass feedstock production for important environmental metrics such as NER and GWP.

These results indicate the importance of spatial variability in the environmental impacts of ethanol feedstock production as well as the potential to reduce environmental impacts by intelligent landscape design and choice of production practices. For example, the most environmentally favorable outcomes appear consistently in the eastern portion of the WI RIMA (Fig. 3). It is interesting to note, however, that this is considered to be prime agricultural land in WI. Therefore, it is somewhat unlikely that SG would be grown in this area unless the price paid for SG can compete with other commodity crops. A better locational target for SG production could be watersheds that achieve reasonable NERs (i.e., not prime agricultural land) and minimize other environmental impacts such as the southwest corner of WI under medium nitrogen application.

Ethanol Production

The highest NER occurs in the WIHN DA scenario, in part, because the yields for this scenario were quite high (12 Mg SG dry matter ha−1 on average), and a higher yield from this scenario means that more ethanol was produced. The AFEX pretreatment had a lower NER and higher GWP compared to the DA pretreatment since the additional energy required for ammonia recovery reduced the total excess electricity available for export to displace grid electricity. Additionally, all of the MI scenarios had lower GWP than the WI scenarios because the MI grid uses more coal and less natural gas for electricity generation than the WI grid. Therefore, each unit of electricity displaced in MI avoids more GHG emissions than in WI. Similar effects were observed in the AP results due to relative emissions of NOx and SOx.

The high nitrogen application rate scenarios resulted in higher GWP from both the increased need to produce fertilizer and the increased N2O emissions from soils. Increased nitrogen application did not significantly increase the NER, but it did increase the GWP, AP, and EP in most areas. Differences in EP were primarily a function of nitrogen application rate. Negative values for EP indicate that the EP from SG production was significantly less than that of the baseline scenario. Therefore, the potential for eutrophication is lessened by this land use change from a conventional corn-soybean management to SG production.

The GWP intensity across all eight scenarios was influenced by variation in the CO2 and N2O emissions from soils due to cultivation and by variations in yield (Fig. 4). The influence of spatial variations in GHG emissions from soils and yield is greater in WI than in MI. Biomass yield is an important determinant of overall efficiencies. For example, a larger SG yield from the same area with the same amount of inputs and tillage will reduce the overall GWP per mass of SG that is carried forward to the biorefinery. Across all scenarios, spatial variability in GHG emissions from soils contributed four to five times more to the change in the GWP intensity than variations in yield. It is clear that the absorption and emission of abiotic and biotic carbon are the primary driver of the overall GWP intensity of SG ethanol.

The NER for the full ethanol production LCA is not sensitive to variations in liming (less than 1 % change in NER), but the energy inputs to the cropping system are sensitive to lime. In WI, the NER changes by as much as 20 % if the lime application rate is varied by one SD from its spatial mean, while, in MI, this value changes by less than 5 %. The NER was also changed by less than 0.5 % across all scenarios when yields were varied by one SD from their spatial mean. The primary contributor to input energy was the energy used to produce inputs to production such as chemicals for agricultural production, pretreatment, cellulase production, and denaturation (Fig. 5).

The combustion of fossil fuels for field operations, transportation, and the production of biorefinery chemicals and enzymes was the primary contributor to AP, and emissions from soils were not a significant contributor (Fig. 6). The avoided combustion of fossil fuels (e.g., coal and natural gas) from electricity displacement provided a substantial benefit to the AP of the fuel. The final AP value for the LCA was not sensitive to spatial variation in SG production (less than 1 % change). By contrast, EP was sensitive to spatial variations in the modeled nitrogen and phosphorus losses from soils via runoff, sediment, lateral subsurface flow, and percolation below the root zone. The change from the baseline conventional corn-soybean production to SG production substantially reduced the EP of the ethanol production in WI but was decidedly sensitive to spatial variation in the all scenarios (Fig. 7).

Conclusions

In this study, we put forth a cellulosic ethanol LCA which considers spatial variation, local environmental uniqueness, and variations in biomass feedstock and ethanol production methods as well as the upstream impacts of the production of agricultural and industrial system inputs. Accomplishing this task required integrating the efforts of many researchers into one comprehensive yet flexible LCA. We collaborated with many researchers under the umbrella of the GLBRC to obtain biogeochemical, biophysical, electricity grid, and biorefinery data. This type of research can aid in identifying the most significant environmental impacts of ethanol production and spur further research on how to reduce these impacts. Biofuel production is a field that is experiencing significant change and development, providing an ideal opportunity to guide this field toward a more sustainable system.

The spatial variations observed in this study indicate that spatial averages of yields and emissions over large areas (like counties, states, or countries) introduce significant variability into the results of LCAs that involve agricultural production. When spatial averages are used for a county, state, or country, data on the SDs from these averages are not available; therefore, the sensitivity of the results to actual spatial variation in these parameters cannot be tested. The maps in Fig. 3 illustrate the variation in yields and environmental impact metrics in a single county. By using modeled data with SDs, we were able to test the sensitivity of the LCA results to spatial variations. In addition to this, the location of the biorefinery determined the electricity grid mix displaced by the coproduct electricity generation which affected the GWP and the AP of the fuel. Therefore, the types and ratios of fossil fuels used to produce power in each region are an important LCA factor for any system that also produces electricity.

The scenarios with the lowest AP and EP are WIHN AFEX and WIMN AFEX, but these scenarios have some of the highest GWP intensities and lowest NERs. Still, both WIHN AFEX and WIMN AFEX have higher NERs than corn grain ethanol (1.25 according to Hill et al. [2]). This analysis is just one example of how a spatially explicit and flexible LCA model of cellulosic ethanol production could be used to evaluate the environmental impacts of several scenarios simultaneously and check that a fuel production scenario meets standards even with potential variations in metrics due to spatial variability.

In this study, we demonstrated the importance of spatially explicit agricultural and electricity grid data in the LCA of biofuels. This type of research can aid in identifying the most significant environmental impacts of ethanol production and spur further research on how to reduce these impacts. Future spatially explicit LCA modeling could include local biomass processing depots (LBPDs) placed in spatially optimized locations on the landscape [52, 53] and the coproduction of animal feeds from pretreatment [54]. The addition of economic variables for the biomass selling price for “profit-oriented farmers” in a given region [55] and techno-economic variables for the costs of ethanol production for a given technology [56] would also enhance the analysis. The addition of these factors would make the model into a robust decision support tool for evaluating the effects of the location of a biorefinery in terms of its economic viability, environmental sustainability, and ability to meet policy standards. Additionally, no previous study has quantified the spatial variability in yield and emissions at the small scale from which actual SG biomass would be drawn for an actual commercial-scale SG cellulosic ethanol plant. The results of this study could be used to estimate the emission uncertainty involved in agricultural production for the purposes of evaluating if SG ethanol production meets biofuel standards. Advanced modeling techniques provide the data necessary to give agricultural production the spatially explicit treatment required to conduct a thorough LCA and address the grand challenges identified in this field.

References

Farrell AE, Plevin RJ, Turner BT, Jones AD, O’Hare M, Kammen DM (2006) Ethanol can contribute to energy and environmental goals. Science 311(5760):506–508. doi:10.1126/science.1121416

Hill J, Nelson E, Tilman D, Polasky S, Tiffany D (2006) Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc Natl Acad Sci U S A 103(30):11206–11210. doi:10.1073/pnas.0604600103

Hsu DD, Inman D, Heath GA, Wolfrum EJ, Mann MK, Aden A (2010) Life cycle environmental impacts of selected US ethanol production and use pathways in 2022. Environ Sci Technol 44(13):5289–5297. doi:10.1021/es100186h

Liska AJ, Yang HS, Bremer VR, Klopfenstein TJ, Walters DT, Erickson GE, Cassman KG (2009) Improvements in life cycle energy efficiency and greenhouse gas emissions of corn-ethanol. J Ind Ecol 13(1):58–74. doi:10.1111/j.1530-9290.2008.00105.x

Pimentel D (2003) Ethanol fuels: energy balance, economics, and environmental impacts are negative. Natural Resources Research, vol 12

Sinistore JC, Bland WL (2009) Life-cycle analysis of corn ethanol production in the Wisconsin context. Biol Eng 2(3):147–163

Wu M, Wang M, Huo H (2006) Fuel-cycle assessment of selected bioethanol production pathways in the United States. Argonne, IL

Hill J, Polasky S, Nelson E, Tilman D, Huo H, Ludwig L, Neumann J, Zheng HC, Bonta D (2009) Climate change and health costs of air emissions from biofuels and gasoline. Proc Natl Acad Sci U S A 106(6):2077–2082. doi:10.1073/pnas.0812835106

Fu GZ, Chan AW, Minns DE (2003) Life cycle assessment of bio-ethanol derived from cellulose. Int J Life Cycle Assess 8(3):137–141. doi:10.1065/lca2003.03.109

Schmer MR, Vogel KP, Mitchell RB, Perrin RK (2008) Net energy of cellulosic ethanol from switchgrass. Proc Natl Acad Sci U S A 105(2):464–469. doi:10.1073/pnas.0704767105

Qin X, Zhuang Q, Cai X (2014) Bioenergy crop productivity and potential climate change mitigation from marginal lands in the United States: an ecosystem modeling perspective. GCB Bioenergy. doi:10.1111/gcbb.12212

Tonini D, Hamelin L, Wenzel H, Astrup T (2012) Bioenergy production from perennial energy crops: a consequential LCA of 12 bioenergy scenarios including land use changes. Environ Sci Technol 46(24):13521–13530. doi:10.1021/es3024435

Spatari S, Bagley DM, MacLean HL (2010) Life cycle evaluation of emerging lignocellulosic ethanol conversion technologies. Bioresour Technol 101(2):654–667. doi:10.1016/j.biortech.2009.08.067

Laser M, Jin HM, Jayawardhana K, Lynd LR (2009) Coproduction of ethanol and power from switchgrass. Biofuels Bioprod Biorefin Biofpr 3(2):195–218. doi:10.1002/bbb.133

Scown CD, Nazaroff WW, Mishra U, Strogen B, Lobscheid AB, Masanet E, Santero NJ, Horvath A, McKone TE (2012) Lifecycle greenhouse gas implications of US national scenarios for cellulosic ethanol production. Environ Res Lett 7 (1\). doi:10.1088/1748-9326/7/1/014011

Johnston M, Foley JA, Holloway T, Kucharik C, Monfreda C (2009) Resetting global expectations from agricultural biofuels. Environ Res Lett 4 (1). doi:10.1088/1748-9326/4/1/014004

McKone TE, Nazaroff WW, Berck P, Auffhammer M, Lipman T, Torn MS, Masanet E, Lobscheid A, Santero N, Mishra U, Barrett A, Bomberg M, Fingerman K, Scown C, Strogen B, Horvath A (2011) Grand challenges for life-cycle assessment of biofuels. Environ Sci Technol 45(5):1751–1756. doi:10.1021/es103579c

Reap J, Roman F, Duncan S, Bras B (2008) A survey of unresolved problems in life cycle assessment. Int J Life Cycle Assess 13(5):374–388. doi:10.1007/s11367-008-0009-9

Potting J, Hauschild MZ (2006) Spatial differentiation in life cycle impact assessment—a decade of method development to increase the environmental realism of LCIA. Int J Life Cycle Assess 11:11–13. doi:10.1065/lca2006.04.005

Zhang X, Izaurralde RC, Manowitz D, West TO, Post WM, Thomson AM, Bandaruw VP, Nichols J, Williams JR (2010) An integrative modeling framework to evaluate the productivity and sustainability of biofuel crop production systems. Glob Chang Biol Bioenergy 2(5):258–277. doi:10.1111/j.1757-1707.2010.01046.x

Brown RC (2003) Biorenewable resources: engineering new products from agriculture. Blackwell Publishing Professional, Ames

Humbird D, Davis R, Tao L, Kinchin C, Hsu D, Aden A, Schoen P, Lukas J, Olthof B, Worley M, Sexton D, Dudgeon D (2011) Process design and economics for biochemical conversion of lignocellulosic biomass to ethanol: dilute-acid pretreatment and enzymatic hydrolysis of corn stover. National Renewable Energy Laboratory, Golden

MacLean HL, Spatari S (2009) The contribution of enzymes and process chemicals to the life cycle of ethanol. Environ Res Lett 4 (1). doi:10.1088/1748-9326/4/1/014001

Bright RM, Stromman AH (2009) Life cycle assessment of second generation bioethanols produced from Scandinavian boreal forest resources a regional analysis for Middle Norway. J Ind Ecol 13(4):514–531. doi:10.1111/j.1530-9290.2009.00149.x

Curran MA (2007) Studying the effect on system preference by varying coproduct allocation in creating life-cycle inventory. Environ Sci Technol 41(20):7145–7151. doi:10.1021/es070033f

Luo L, van der Voet E, Huppes G, de Haes HAU (2009) Allocation issues in LCA methodology: a case study of corn stover-based fuel ethanol. Int J Life Cycle Assess 14(6):529–539. doi:10.1007/s11367-009-0112-6

PE (2006) GaBi 4: the software system for life cycle engineering. PE International, PE-Europe GmbH and IKP University of Stuttgart

ISO (2006) ISO 14040: environmental management—life cycle assessment—principles and framework. International Organization for Standardization, Geneva

ISO (2006) ISO 14044: environmental management—life cycle assessment—life cycle impact assessment. International Organization for Standardization, Geneva

SSURGO (2012) Soil Survey Geographic (SSURGO) Database for Wisconsin and Michigan. Soil Survey Staff, Natural Resources Conservation Service, United States Department of Agriculture

He X, Izaurralde RC, Vanotti MB, Williams JR, Thomson AM (2006) Simulating long-term and residual effects of nitrogen fertilization on corn yields, soil carbon sequestration, and soil nitrogen dynamics. J Environ Qual 35(4):1608–1619. doi:10.2134/jeq2005.0259

Izaurralde RC, Williams JR, Post WM, Thomson AM, McGill WB, Owens LB, Lal R (2007) Long-term modeling of soil C erosion and sequestration at the small watershed scale. Clim Chang 80(1–2):73–90. doi:10.1007/s10584-006-9167-6

Izaurralde RC, McGill WB, Williams JR (2012) Development and application of the EPIC model for carbon cycle, greenhouse gas mitigation, and biofuel studies. Managing agricultural greenhouse gases: coordinated agricultural research through GRACEnet to address our changing climate: 293-308. doi:10.1016/b978-0-12-386897-8.00017-6

Wang X, Williams JR, Gassman PW, Baffaut C, Izaurralde RC, Jeong J, Kiniry JR (2012) EPIC and APEX: model use, calibration, and validation. Trans ASABE 55(4):1447–1462

NREL (2008) U.S. Life-Cycle Inventory (LCI) Database. National Renewable Energy Laboratory

Centre E (2007) Ecoinvent Eata. v2.0. Ecoinvent reports 1-25. Swiss centre for life cycle inventories. Dübendorf

Meier PJ (2012) myPower methodology documentation

Agency USEP (2010) National Electric Energy Data System (NEEDS)

Agency USEP (2010) EPA’s IPM Base Case 2006 (v3.0) Comprehensive modeling documentation

2010 ANLA Greenhouse gases, Regulated Emissions, and Energy use in Transportation Model, GREET Version 1.8C. Accessed March 2010

Sinistore JC (2008) Corn ethanol production in the Wisconsin agricultural context: energy efficiency, greenhouse gas neutrality and soil and water implications. University of Wisconsin-Madison, Madison

Lange M (2011) The GHG balance of biofuels taking into account land use change. Energ Policy 39(5):2373–2385. doi:10.1016/j.enpol.2011.01.057

Searchinger T, Heimlich R, Houghton RA, Dong F, Elobeid A, Fabiosa J, Tokgoz S, Hayes D, Yu T-H (2008) Use of US croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 319(5867):1238–1240. doi:10.1126/science.1151861

Mathews JA, Tan H (2009) Biofuels and indirect land use change effects: the debate continues. Biofuels Bioprod Biorefin Biofpr 3(3):305–317. doi:10.1002/bbb.147

Kim S, Dale BE (2011) Indirect land use change for biofuels: testing predictions and improving analytical methodologies. Biomass Bioenergy 35(7):3235–3240. doi:10.1016/j.biombioe.2011.04.039

O’Hare M, Delucchi M, Edwards R, Fritsche U, Gibbs H, Hertel T, Hill J, Kammen D, Laborde D, Marelli L, Mulligan D, Plevin R, Tyner W (2011) Comment on “Indirect land use change for biofuels: testing predictions and improving analytical methodologies” by Kim and Dale: statistical reliability and the definition of the indirect land use change (iLUC) issue. Biomass Bioenergy 35(10):4485–4487. doi:10.1016/j.biombioe.2011.08.004

Dale BE, Kim S (2011) Response to comments by O’Hare et al., on the paper indirect land use change for biofuels: testing predictions and improving analytical methodologies. Biomass Bioenergy 35(10):4492–4493. doi:10.1016/j.biombioe.2011.08.003

Gawel E, Ludwig G (2011) The iLUC dilemma: how to deal with indirect land use changes when governing energy crops? Land Use Policy 28(4):846–856. doi:10.1016/j.landusepol.2011.03.003

Kline KL, Oladosu GA, Dale VH, McBride AC (2011) Scientific analysis is essential to assess biofuel policy effects: in response to the paper by Kim and Dale on “Indirect land-use change for biofuels: testing predictions and improving analytical methodologies”. Biomass Bioenergy 35(10):4488–4491. doi:10.1016/j.biombioe.2011.08.011

Haberl H, Sprinz D, Bonazountas M, Cocco P, Desaubies Y, Henze M, Hertel O, Johnson RK, Kastrup U, Laconte P, Lange E, Novak P, Paavola J, Reenberg A, van den Hove S, Vermeire T, Wadhams P, Searchinger T (2012) Correcting a fundamental error in greenhouse gas accounting related to bioenergy. Energ Policy 45:18–23. doi:10.1016/j.enpol.2012.02.051

Izaurralde RC, Williams JR, McGill WB, Rosenberg NJ, Jakas MCQ (2006) Simulating soil C dynamics with EPIC: model description and testing against long-term data. Ecol Model 192(3–4):362–384. doi:10.1016/j.ecolmodel.2005.07.010

Eranki PL, Dale BE (2011) Comparative life cycle assessment of centralized and distributed biomass processing systems combined with mixed feedstock landscapes. Glob Chang Biol Bioenergy 3(6):427–438. doi:10.1111/j.1757-1707.2011.01096.x

Eranki PL, Manowitz DH, Bals BD, Izaurralde RC, Kim S, Dale BE (2013) The watershed-scale optimized and rearranged landscape design (WORLD) model and local biomass processing depots for sustainable biofuel production: integrated life cycle assessments. Biofuels Bioprod Biorefin Biofpr 7(5):537–550. doi:10.1002/bbb.1426

Dale BE, Bals BD, Kim S, Eranki P (2010) Biofuels done right: land efficient animal feeds enable large environmental and energy benefits. Environ Sci Technol 44(22):8385–8389. doi:10.1021/es101864b

Egbendewe-Mondzozo A, Swinton SM, Izaurralde CR, Manowitz DH, Zhang XS (2011) Biomass supply from alternative cellulosic crops and crop residues: a spatially explicit bioeconomic modeling approach. Biomass Bioenergy 35(11):4636–4647. doi:10.1016/j.biombioe.2011.09.010

Kazi FK, Fortman JA, Anex RP, Hsu DD, Aden A, Dutta A, Kothandaraman G (2010) Techno-economic comparison of process technologies for biochemical ethanol production from corn stover. Fuel 89:S20–S28. doi:10.1016/j.fuel.2010.01.001

Acknowledgments

This work was funded by the Department of Energy Great Lakes Bioenergy Research Center (DOE BER Office of Science DE-FC02-07ER64494 and DOE OBP Office of Energy Efficiency and Renewable Energy DE-AC05-76RL01830). The authors also gratefully acknowledge the contributions of Bryan Bals, Bruce Dale, David Duncan, Pragnya Eranki, Shujiang Kang, David Manowitz, Timothy D. Meehan, Mac Post, and Xuesong Zhang to this work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 32 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Sinistore, J.C., Reinemann, D.J., Izaurralde, R.C. et al. Life Cycle Assessment of Switchgrass Cellulosic Ethanol Production in the Wisconsin and Michigan Agricultural Contexts. Bioenerg. Res. 8, 897–909 (2015). https://doi.org/10.1007/s12155-015-9611-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-015-9611-4