Abstract

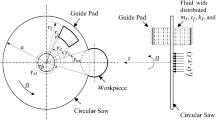

This paper reports on new research that: characterizes the influence of regenerative lateral forces on the stability of metal circular sawing; describes the role of process damping in potentially stabilizing the sawing process; and investigates the role that distributed and lubricated guides play in a sawing process prone to regenerative instabilities. We model the saw as a rotating disc using the Von Kármán plate theory. Equations of motion are derived using the Hamilton’s principle. Guides are modelled as being distributed and properties of the fluid are modelled to be a function of the guide size and its placement relative to the saw. The regenerative and process damping effects are incorporated based on other similar models for milling processes. Our model-based analysis suggests that: regenerative instabilities are characterized by a growth in the real part of the eigenvalue of the system; clearance between the guide and the rotating saw and the guide’s circumferential placement with respect to the cutting zone both influence the severity and speed regions of instabilities; material being cut and changing cutting engagements do not significantly influence the region of instabilities; and that process damping can help stabilize an otherwise unstable process. Though models need to be validated, our observations can still instruct the design of stable guided metal sawing processes in industries.

Similar content being viewed by others

References

Zhuo R, Deng Z, Chen B, Guoyue L and Bi S 2021 Overview on development of acoustic emission monitoring technology in sawing. Int. J. Adv. Manuf. Technol. 116: 1411–1427. https://doi.org/10.1007/s00170-021-07559-5.

Singhania S, Singh A and Law M 2022 Dynamics and stability of metal cutting circular saws with distributed and lubricated guides. J. Vib. Eng. Technol. 10: 3119–3131. https://doi.org/10.1007/s42417-022-00544-6.

Altintas Y and Weck M 2004 Chatter stability of metal cutting and grinding. CIRP Ann. Manuf. Technol. 53: 619–642. https://doi.org/10.1016/S0007-8506(07)60032-8.

Munoa J, Beudaert X, Dombovari Z, Altintas Y, Budak E, Brecher C and Stepan G 2016 Chatter suppression techniques in metal cutting. CIRP Ann. Manuf. Technol. 65: 785–808. https://doi.org/10.1016/j.cirp.2016.06.004.

Altintas Y, Stepan G, Budak E, Schmitz T and Kilic Z M 2020 Chatter stability of machining operations. J. Manuf. Sci. Eng. Trans. ASME. https://doi.org/10.1115/1.4047391.

Tian J and Hutton S G 1999 Self-excited vibration in flexible rotating disks subjected to various transverse interactive forces: a general approach. J. Appl. Mech. Trans. ASME 66: 800–805. https://doi.org/10.1115/1.2791758.

Tian J F and Hutton S G 2001 Cutting-induced vibration in circular saws. J. Sound Vib. 242: 907–922. https://doi.org/10.1006/jsvi.2000.3397.

Zäh M F 1995 Dynamic process model circular saws, PhD thesis.

Singhania S and Law M 2021 Regenerative instabilities of spring-guided circular saws. Procedia CIRP 101: 142–145. https://doi.org/10.1016/j.procir.2021.02.017.

Singhania S and Law M 2023 Influence of process damping on the regenerative instability of guided metal circular sawing. Manuf. Technol. Today 22: 20–25.

Wallace P W and Andrew C 1965 Machining forces: some effects of tool vibration. J. Mech. Eng. Sci. 7: 152–162. https://doi.org/10.1243/jmes_jour_1965_007_023_02.

Tyler C T and Schmitz T L 2013 Analytical process damping stability prediction. J. Manuf. Process. 15: 69–76. https://doi.org/10.1016/j.jmapro.2012.11.006.

Eynian M and Altintas Y 2010 Analytical chatter stability of milling with rotating cutter dynamics at process damping speeds. ASME. J. Manuf. Sci. Eng. 132: 021012. https://doi.org/10.1115/1.4001251.

Sahu G N, Jain P, Law M and Wahi P 2023 Emulating chatter with process damping in turning using a hardware-in-the-loop simulator. In: Advances in Forming, Machining and Automation. Lecture Notes in Mechanical Engineering (eds) Dixit U S, Kanthababu M, Ramesh Babu A and Udhayakumar S, Springer, Singapore. https://doi.org/10.1007/978-981-19-3866-5_22.

Tunc L T and Budak E 2013 Identification and modeling of process damping in milling. J. Manuf. Sci. Eng. 135: 1–12. https://doi.org/10.1115/1.4023708.

Tuysuz O and Altintas Y 2019 Analytical modeling of process damping in machining. J. Manuf. Sci. Eng. Trans. ASME 141: 1–16. https://doi.org/10.1115/1.4043310.

Schajer G S 1986 Why are guided circular saws more stable than unguided saws? Holz Als Roh Und Werkst 44: 465–469. https://doi.org/10.1007/bf02608068.

Khorasany R M H, Panah A M and Hutton S G 2012 Vibration characteristics of guided circular saws: experimental and numerical analyses. J. Vib. Acoust. Trans. ASME. DOI 10(1115/1): 4006650.

Singhania S, Kumar P, Gupta S K and Law M 2019 Influence of guides on critical speeds of circular saws. In: Advances in Computational Methods in Manufacturing. Lecture Notes on Multidisciplinary Industrial Engineering (eds) Narayanan R, Joshi S and Dixit U, Springer, Singapore. https://doi.org/10.1007/978-981-32-9072-3_45.

Altintaş Y and Budak E 1995 Analytical prediction of stability lobes in milling. CIRP Ann. Manuf. Technol. 44: 357–362. https://doi.org/10.1016/S0007-8506(07)62342-7.

Mathews J H 1992 Numerical methods for mathematics, science and engineering. 2nd edn. Prentice-Hall International, Hoboken.

Singhania S 2023 Dynamics and stability of metal cutting circular saws constrained with lubricated guides, Ph.D. thesis, Indian Institute of Technology Kanpur, India

Acknowledgment

This research was supported by the Government of India’s Science and Engineering Research Board’s Early Career Research Award—SERB/ECR/2016/000619. The authors also acknowledge Mr. Anurag Singh for his insightful technical inputs.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singhania, S., Law, M. Regenerative instabilities in guided metal circular sawing. Sādhanā 49, 97 (2024). https://doi.org/10.1007/s12046-024-02442-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-024-02442-x