Abstract

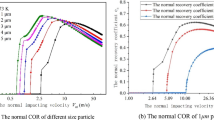

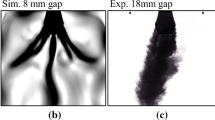

In this paper, the effects of channel roughness on the droplet removal efficiency and pressure drop in a zigzag mist eliminator are investigated. The fluid flow, droplet dispersion and deposition through the demister are modelled using a commercial Computational Fluid Dynamics (CFD) tool. The turbulent airflow is simulated using two different Shear-stress Transport (SST) k-ω model and Reynolds Stress Model (RSM) with enhanced wall treatment. The Eddy Interaction Model (EIM) is also used to predict the trajectories of the droplets in the gas flow. The results show that inserting roughness increases the maximum velocity of the gas flow at the bends and enhances the removal efficiency with a little cost of an increase in the pressure drop for each bend. At the velocity inlet of 2 m/s with 6 μm droplets, the pressure drop and removal efficiency of the threaded zigzag demister with 5 threads increases by 22.7% and 16.08 %, respectively. Moreover, a higher value for the figure of merit is achieved for the threaded demister compared with the smooth unit which means that the effect of higher removal efficiency of the threaded unit is more pronounced than the effect of higher pressure drop showing the advantages of adding threads in demisters.

Similar content being viewed by others

Abbreviations

- \( C_{D} \) :

-

Drag coefficient [-]

- \( C_{L} \) :

-

Discrete phase model constant [-]

- \( d \) :

-

Droplet diameter [μm]

- \( D_{\omega } \) :

-

Cross-diffusion term [kg/m3s2]

- \( F_{D} \) :

-

Coefficient in drag force calculation [1/s]

- \( F_{x} \) :

-

Additional acceleration [m/s2]

- \( g_{x} \) :

-

Gravitational acceleration [m/s2]

- \( \tilde{G}_{k} \) :

-

Production of turbulence kinetic energy [kg/ms3]

- \( G_{k} \) :

-

Production of turbulence kinetic energy [kg/ms3]

- \( G_{\omega } \) :

-

Production of ω [kg/m3s2]

- \( k \) :

-

Turbulence kinetic energy [m2/s2]

- \( L_{e} \) :

-

Eddy length scale [m]

- \( n \) :

-

Number of bends [-]

- \( r \) :

-

Random number [-]

- \( \text{Re}_{r} \) :

-

Relative Reynolds number [-]

- \( \text{Re}_{ij} \) :

-

Reynolds stress tensor [m2/s2]

- \( s \) :

-

Surface of sphere with same volume [m2]

- \( S \) :

-

Actual surface of the droplet [m2]

- \( S \) :

-

Width of the demister channel [mm]

- \( S_{\varphi } \) :

-

Source term in transport equation

- \( t_{cross} \) :

-

Droplet eddy crossing time [s]

- \( T_{L} \) :

-

Integral time [s]

- \( u^{\prime} \) :

-

Fluctuation of gas flow velocity [m/s]

- \( \bar{u} \) :

-

Mean fluid phase velocity [m/s]

- \( u \) :

-

Fluid phase velocity [m/s]

- \( u_{p} \) :

-

Droplet velocity [m/s]

- \( Y_{k} \) :

-

Dissipation of kinetic energy [kg/ms3]

- \( Y_{\omega } \) :

-

Dissipation of ω [kg/m3s2]

- \( \varGamma_{k} \) :

-

Effective diffusivity of kinetic energy [kg/ms]

- \( \varGamma_{\omega } \) :

-

Effective diffusivity of \( \omega \) [kg/ms]

- \( \varGamma_{\varphi } \) :

-

Diffusion coefficient in transport equation

- \( \eta \) :

-

Droplet removal efficiency [%]

- \( \eta_{B} \) :

-

Efficiency of each bend [%]

- \( \alpha \) :

-

Bend angle [-]

- \( \varepsilon \) :

-

Dissipation rate [m2/s3]

- \( \lambda \) :

-

Bend wavelength [mm]

- \( \mu_{t} \) :

-

Turbulent viscosity [kg/ms]

- \( \mu \) :

-

Molecular viscosity of the fluid [kg/ms]

- \( \rho_{p} \) :

-

Droplet density [kg/m3]

- \( \rho \) :

-

Gas density [kg/m3]

- \( \rho_{d} \) :

-

Droplet density [kg/m3]

- \( \sigma_{k} \) :

-

Turbulent Prandtl number for k [-]

- \( \sigma_{\omega } \) :

-

Turbulent Prandtl number for ω [-]

- \( \tau \) :

-

Droplet relaxation time [s]

- \( \nu \) :

-

Gas bulk velocity at inlet [m/s]

- \( \omega \) :

-

Specific dissipation rate [1/s]

- \( \phi \) :

-

Shape factor [-]

- \( \varsigma \) :

-

Normally distributed random number [-]

- \( \varphi \) :

-

General variable in transport equation

References

Calvert S, Jashnani IL and Yung S 1974 Entrainment separators for scrubbers. J. Air Pollut. Control Assoc. 24: 971-975

Chan JK-K and Golay M W Comparative evaluation of cooling tower drift eliminator performance. MIT Energy Laboratory: MIT Energy Laboratory, 1977

Ushiki K, Nishzawa E, Beniko H and Iinoya K 1982 Performance of a droplet separator with multistage rows of flat blades. J. Chem. Eng. Jpn. 15: 292-298

Phillips H and Deakin A Measurements of the collection efficiency of various demister devices. In: Proceedings of the Fourth Annual Meeting of the Aerosol Society, Loughborough, 1990

Jøsang A I Numerical and Experimental Studies of Droplet-Gas Flow, Norwegian University of Science and Technology, 2002

Bürkholz A 1989 Droplet separation: VCH Verlagsgesellschaft

Gillandt I, Fritsching U and Riehle C 1996 Gas-particle flow in a comparison of measurements and simulations. FORSCH INGENIEURWES 62: 315

Wang W and Davies G 1996 CFD studies of separation of mists from gases using vane-type separators. Chem. Eng. Res. Des. 74: 232-238

Wang Y and James P 1998 The calculation of wave-plate demister efficiencies using numerical simulation of the flow field and droplet motion. Chem. Eng. Res. Des. 76: 980-985

Wang YI and James PW 1999 Assessment of an Eddy-Interaction Model and Its Refinements Using Predictions of Droplet Deposition in a Wave-Plate Demister. Chem. Eng. Res. Des. 77: 692-698

Galletti C, Brunazzi E and Tognotti L 2008 A numerical model for gas flow and droplet motion in wave-plate mist eliminators with drainage channels. Chem. Eng. Sci. 63: 5639-5652

Rafee R and Rahimzadeh H 2010 Performance Evaluation of a Curved Type Vane Separator at Different Plate Spacings in the Range of 25 to 35mm Using Numerical Simulation. Iran J. Chem. Chem. Eng. 29 (3)

Rafee R, Rahimzadeh H and Ahmadi G 2010 Numerical simulations of airflow and droplet transport in a wave-plate mist eliminator. Chem. Eng. Res. Des. 88: 1393-1404

McNulty K, Monat J and Hansen O 1987 Performance of commercial chevron mist eliminators. Chem. Eng. Prog. 83: 48-55

James P W, Wang Y, Azzopardi B J and Hughes J P 2003 The Role of Drainage Channels in the Performance of Wave-Plate Mist Eliminators. Chem. Eng. Res. Des. 81: 639-648

Brunazzi E, Ghetti S, Merello C and Paglianti A 2004 Experimental study of the re-entrainment in wave-plate demisters. Proceedings of Convegno Gricu. 1:625-628

Estakhrsar M H H and Rafee R 2013 Effect of drainage channel dimensions on the performance of wave-plate mist eliminators. Korean J. Chem. Eng. 30: 1301-1311

Hamedi Estakhrsar M H and Rafee R 2016 Effects of wavelength and number of bends on the performance of zigzag demisters with drainage channels. Appl. Math. Model. 40: 685-699

Lei G, Zhulin Y, Linjun Y and Zhongzhu G 2016 Numerical Study on the Penetration of Droplets in a Zigzag Demister. Environ. Eng. Sci. 33: 35-43

Verlaan C C J Performance of novel mist eliminators 1991

Houghton H and Radford W 1939 Measurements on eliminators and the development of a new type for use at high gas velocities. Trans. Am. Inst. Chem. Eng. 35: 427-433

Azzopardi J and Sanaullah K 2002 Re-entrainment in wave-plate mist eliminators. Chem. Eng. Sci. 57: 3557-3563

Banitabaei S A, Rahimzadeh H and Rafee R 2012 Determination of minimum pressure drop at different plate spacings and air velocity in a wave-plate mist eliminator. Asia-Pacific J. Chem. Eng. 7: 590-597

Xu Y, Yang Z and Zhang J 2017 Study on performance of wave-plate mist eliminator with porous foam layer as enhanced structure. Part II: Experiments. Chem. Eng. Sci. 171: 662-671

Xu Y, Yang Z and Zhang J 2017 Study on performance of wave-plate mist eliminator with porous foam layer as enhanced structure. Part I: Numerical simulation. Chem. Eng. Sci. 171: 650-661

Hamedi Estakhrsar M and Rafee R 2013 Effect of drainage channel dimensions on the performance of wave-plate mist eliminators. Korean J. Chem. Eng. 1-11

Zhang Z, Zhang W, Zhai Z J and Chen Q Y 2007 Evaluation of Various Turbulence Models in Predicting Airflow and Turbulence in Enclosed Environments by CFD: Part 2—Comparison with Experimental Data from Literature. HVAC&R Res. 13: 871-886

Xiao H and Cinnella P 2019 Quantification of model uncertainty in RANS simulations: A review. Prog. Aerosp. Sci. 108: 1-31

Menter FR 1994 Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 32: 1598-1605

Launder BE 1989 Second-moment closure: present… and future? Int. J. Heat Fluid Flow 10: 282-300

Lien F-S and Leschziner M 1994 Assessment of turbulence-transport models including non-linear RNG eddy-viscosity formulation and second-moment closure for flow over a backward-facing step. Comput. Fluids 23: 983-1004

Talebizadeh P, Rahimzadeh H, Babaie M, Javadi Anaghizi J, Ghomi HR, Ahmadi G, and Brown R 2015 Evaluation of residence time on nitrogen oxides removal in non-thermal plasma reactor. Plos One 10: e0140897

Fluent A ANSYS Fluent 12.0 user’s guide. Ansys Inc. 2009; 15317:1-2498

Maxey MR and Riley JJ 1983 Equation of motion for a small rigid sphere in a nonuniform flow. Phys. Fluids 26: 883-889

Sardari P T, Rahimzadeh H, Ahmadi G and Giddings D 2018 Nano-particle deposition in the presence of electric field. J. Aerosol Sci. 126: 169-179

Li A and Ahmadi G 1992 Dispersion and deposition of spherical particles from point sources in a turbulent channel flow. Aerosol Sci. Tech. 16: 209-226

Talebizadehsardari P, Rahimzadeh H, Ahmadi G, Moghimi M A, Inthavong K and Esapour M 2019 Nano-particle deposition in axisymmetric annular pipes with thread. Part. Sci. Technol. 1-9

Saffman P 1965 The lift on a small sphere in a slow shear flow. J. Fluid Mech. 22: 385-400

Talebizadeh P, Rahimzadeh H, Ahmadi G, Brown R and Inthavong K 2016. Time history of diesel particle deposition in cylindrical dielectric barrier discharge reactors. J. Nanopart. Res. 18: 378

Haider A and Levenspiel O 1989 Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol. 58: 63-70

Tian L and Ahmadi G 2007 Particle deposition in turbulent duct flows—comparisons of different model predictions. J. Aerosol Sci. 38: 377-397

Launder B E and Spalding D 1974 The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 3: 269-289

Zamora B and Kaiser A S 2011 Comparative efficiency evaluations of four types of cooling tower drift eliminator, by numerical investigation. Chem. Eng. Sci. 66: 1232-1245

James P W, Azzopardi B J, Wang Y and Hughes J P 2005 A Model for Liquid Film Flow and Separation in a Wave-Plate Mist Eliminator. Chem. Eng. Res. Des. 83: 469-477

Zhao J, Jin B and Zhong Z 2007 Study of the separation efficiency of a demister vane with response surface methodology. J. Hazard. Mater. 147: 363-369

Wang Y I and James P W 1998 The Calculation of Wave-Plate Demister Efficiencies Using Numerical Simulation of the Flow Field and Droplet Motion. Chem. Eng. Res. Des. 76: 980-985

Wang Y and James P 1999 Assessment of an eddy-interaction model and its refinements using predictions of droplet deposition in a wave-plate demister. Chem. Eng. Res. Des. 77:692-698

Aftab S, Mohd Rafie A, Razak N and Ahmad K 2016 Turbulence model selection for low Reynolds number flows. PloS one. 11: e0153755

Wang J, Kim S C and Pui D Y H 2008 Investigation of the figure of merit for filters with a single nanofiber layer on a substrate. J. Aerosol Sci. 39: 323-334

Brown R C 1993 Air filtration: an integrated approach to the theory and applications of fibrous filters, Pergamon

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alamshahi, F., Rahimzadeh, H., Rafee, R. et al. Effects of Roughness on the Performance of a threaded Zigzag Demister Using RSM and k − ω turbulent models. Sādhanā 45, 283 (2020). https://doi.org/10.1007/s12046-020-01510-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-020-01510-2