Abstract

The developments around flow processing technology have paved the way for new avenues and perspectives to consider in the field of organic chemistry and engineering. In this study, customized flow equipment was utilized to develop and optimize the Mitsunobu reaction. The flow reactor was a prototype of a simple tubular reactor based on the plug flow reactor concept. The experimentation methodology was designed through the statistical design of experiments approach to minimize the number of experiments. The molar ratios of cyclohexanol (1) and o-cresol (2) and interaction effects of triphenylphosphine, diisopropyl azodicarboxylate were studied in detail. The reaction profile of flow experiments agreed with the batch conditions adding noteworthy improvements to the overall reaction time, selectivity, and yield towards the desired product 1-(cyclohexyloxy)-2-methylbenzene (3). The Mitsunobu reaction in batch condition would take on an average of 3 to 5 h, which was effectively accomplished in 30 to 45 mins in this flow reactor. The generated mathematical model is in good agreement with the reaction conditions. We believe that the process could be executed continuously without a break, readily scaled to kilogram quantities in a short time without further development.

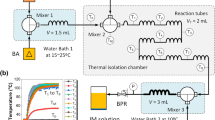

Graphic abstract

Mitsunobhu reaction in continuous process

Similar content being viewed by others

Data transparency

Authors confirm that the paper now submitted is not copied or plagiarized version of some other published work.

References

Lepore Salvotore D and Yuanjun H 2003 Use of sonication for the coupling of sterically hindered substrates in the phenolic Mitsunobu reaction J. Org. Chem. 68 8261

Oyo M 1981 The use of diethyl azodicarboxylate and triphenylphosphine in synthesis and transformation of natural products Synthesis 1981 1

Oyo M and Masaaki Y 1967 Preparation of esters of carboxylic and phosphoric acid via quaternary phosphonium salts Bull. Chem. Soc. Jpn. 40 2380

Kumaraswamy K C, Bhuvan Kumar N N, Balaraman E and Pavan Kumar K V P 2009 Mitsunobu and related reactions: Advances and applications Chem. Rev. 109 2551

Gu Y, Azzouzi A, Pouilloux Y, Jérôme F and Barrault J 2008 Heterogeneously catalyzed etherification of glycerol: new pathways for transformation of glycerol to more valuable chemicals Green Chem. 10 164

Berger A and Wehrstedt K D 2009 Azodicarboxylates: Explosive properties and thermal hazards 12th Annual Symposium, Mary Kay O’Connor process safety center beyond regulatory compliance: Making safety second nature at Texas A&M University, College Station, Texas

Caron S and Thomson N M 2015 Pharmaceutical process chemistry: Evolution of a contemporary data-rich laboratory environment J. Org. Chem. 80 2943

Otman B, Deal M, Farrant E, Tapolczay D and Wheeler R 2008 Continuous flow microwave-assisted reaction optimization and scale-up using fluorous spacer technology Org. Process Res. Dev. 12 1007

Roberge D M, Ducry L, Bieler N, Cretton P and Zimmermann B 2005 Microreactor technology: A revolution for the fine chemical and pharmaceutical industries? Chem. Eng. Technol. 28 318

Norbert K, Gottsponer M, Zimmermann B and Roberge D M 2008 Enabling continuous-flow chemistry in microstructured devices for pharmaceutical and fine-chemical production Chem. Eur. J. 14 7470

Bogdan A R, Poe S L, Kubis D C, Broadwater S J and McQuade D T 2009 The continuous-flow synthesis of Ibuprofen Angew. Chem. Int. Ed. 48 8547

Herath A, Dahl R and Nicholas D P Cosford 2010 Fully automated continuous flow synthesis of highly functionalized imidazo[1,2-a] heterocycles Org. Lett. 12 412

Ryan L H and Jensen K F 2009 Microchemical systems for continuous-flow synthesis Lab Chip. 9 2495

Klaus J, Hessel V, Löwe H and Baerns M 2004 Chemistry in microstructured reactors Angew. Chem. Int. Ed. 43 406

Delville M M E, Nieuwland P J, Janssen P, Koch K, van Hest J C M and Rutjes F P J T 2011 Continuous flow azide formation: Optimization and scale-up Chem. Eng. J. 167 556

Karolin G, Gustafsson T and Seeberger P H 2009 Developing continuous-flow microreactors as tools for synthetic chemists Synlett 15 2382

Aiichiro N, Kim H, Usutani H, Matsuo C and Yoshida J-I 2010 Generation and reaction of cyano-substituted aryllithium compounds using microreactors Org. Biomol. Chem. 8 1212

Andreas H, Filipponi P, Piccioni L, Meisenbach M, Schenkel B, Venturoni F and Sedelmeier J 2016 A simple scale-up strategy for organolithium chemistry in flow mode: From feasibility to kilogram quantities Org. Process Res. Dev. 20 1833

Chaoyu Z, Zhang J and Luo G 2016 Kinetic study and intensification of acetyl guaiacol nitration with nitric acid-acetic acid system in a microreactor J. Flow. Chem. 6 309

Zoé A, Cabassud M, Gourdon C and Tochon P 2008 Heat exchanger/reactors (HEX reactors): Concepts, technologies: State-of-the-art Chem. Eng. Process. Process Intensif. 47 2029

Kaspar K, van Weerdenburg B J A, Verkade J M M, Nieuwland P J, Rutjes F P J T and van Hest J C M 2009 Optimizing the deprotection of the amine protecting p-methoxyphenyl group in an automated microreactor platform Org. Process Res. Dev. 13 1003

René B, van den Broek SA M W, Nieuwland P J, Koch K and Rutjes F P J T 2012 Optimisation and scale-up of α-bromination of acetophenone in a continuous flow microreactor J. Flow. Chem. 2 87

Fabry D C, Sugiono E, Rueping M and Meunier F C 2016 Online monitoring and analysis for autonomous continuous flow self-optimizing reactor systems React. Chem. Eng. 1 165

Antimo G, Mancino V, Filipponi P, Mostarda S and Cerra B 2016 Concepts and optimization strategies of experimental design in continuous-flow processing J. Flow. Chem. 6 167

Nunn C, DiPietro A, Hodnett N, Sun P and Wells K M 2018 High-throughput automated design of experiment (DoE) and kinetic modeling to aid in process development of an API Org. Process Res. Dev. 22 54

Ahmad A, Muhammad I A, Muhammad Y, Hayat K and Ul Hassan Shah M 2013 A comparative study of alkaline hydrolysis of ethyl acetate using design of experiments Iran J. Chem. Chem. Eng. 32 33

Asprey S P and Macchietto S 2000 Statistical tools for optimal dynamic model building Comput. Chem. Eng. 24 1261

Franceschini G and Macchietto S 2008 Model-based design of experiments for parameter precision: State of the art Chem. Eng. Sci. 63 4846

Atkinson A C, Barbara Bogacka B and Bogacki M B 1998 D-and T-optimum designs for the kinetics of a reversible chemical reaction Chemom. Intell. Lab. Syst. 43 185

Gupta A and Chandrajit B 2015 Residence time distribution study for continuous column packed with tea waste biomass Integ. Res. Adv. 2 5

Danckwerts P V 1953 Continuous flow systems: distribution of residence times Chem. Eng. Sci. 2 1

Anderson N G 2001 Practical use of continuous processing in developing and scaling up laboratory processes Org. Process Res. Dev. 5 613

Frank K, Wolff T, Thomas S and Seidel-Morgenstern A 2003 Concentration and residence time effects in packed bed membrane reactors Catal. Today 82 25

El-Deeb, Yussif I, Tian M, Funakoshi T, Matsubara R and Hayashi M 2017 Conversion of cyclohexanones to alkyl aryl ethers by using a Pd/C–ethylene system Eur. J. Org. Chem. 2017 409

Acknowledgements

The authors would like to acknowledge Dr. Jegadeesh Thampi and Dr. Narendra Ambhaikar (Chemical Development, Syngene International Ltd.) for providing adequate support, guidance, and motivation throughout the work.

Funding

This work was supported by Syngene International Ltd., Bengaluru, India, and all the necessary approvals are in place to publish the same.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no competing interests.

Availability of data and materials

The data supporting the results and conclusion are included in this article. Any queries regarding data may be directed to the corresponding author.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary Information (SI)

Supplementary Information (SI)

The supplementary data (experimental procedure, data analysis, and model equations, etc.) associated with this article are available at www.ias.ac.in/chemsci.

Rights and permissions

About this article

Cite this article

BASAVARAJU, G., RAJANNA, R. Development of a continuous process: a perspective for Mitsunobu reaction. J Chem Sci 132, 111 (2020). https://doi.org/10.1007/s12039-020-01822-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12039-020-01822-0