Abstract

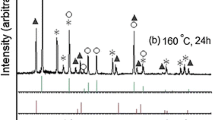

Synthesis of zinc titanates was carried out using a simple precipitation method followed by calcination at different temperatures to obtain different phases of the material. The phase transition characteristics, presence of functional groups, structural aspects and optical bandgaps with respect to calcination temperature were studied by thermal analysis, EDAX, FT-IR, powder XRD, Raman and UV-Vis spectroscopy respectively. The compound on heat treatment at 100∘C for 24 h showed broadened peaks in XRD. With increasing temperature of calcination, the compound appeared to turn to crystalline phase and cubic ZnTiO3 phase was observed at 600∘C. Partial phase transformation of cubic phase ZnTiO3 into hexagonal ilmenite type ZnTiO3 was observed in the temperature range 700∘C to 900∘C. At 1000∘C both cubic and hexagonal ilmenite phases decomposed into cubic phase Zn2TiO 4 and rutile TiO2. FT-IR showed M-O bonds in the range of 400 cm −1 to 700 cm −1. Raman spectra of cubic defect spinel ZnTiO3 and cubic inverse spinel Zn2TiO4 were found to be similar. The optical bandgap calculated using diffuse reflectance spectra was found to be in the range of 3.59 to 3.84 eV depending on calcination temperature.

Zinc titanates were synthesized by a simple precipitation reaction and characterized using thermal analysis, EDAX, powder XRD, FT-IR, Raman and DRS studies. Calcination temperature influences phase transition and optical properties. Raman spectra of cubic ZnTiO3 and cubic Zn2TiO4 are similar due to similarity in their crystal structure and lattice parameters.

Similar content being viewed by others

References

Pineda M, Fierro J L G, Palacios J M, Cilleruelo C, Garcia E and Ibarra J V 1997 Appl. Surf. Sci. 119 1

Pal N, Paul M and Bhaumik A 2011 Appl. Catal., A. 393 153

Wu S P, Luo J H and Cao S X 2010 J. Alloys Compd. 502 147

Yadav B C, Yadav A, Singh S and Singh K 2013 Sens. Actuators B. 177 605

Obayashi H, Sakurai Y and Gejo T 1976 J. Solid State Chem. 17 299

Wang N, Li X, Wang Y, Hou Y, Zou X and Chen G 2008 Mater. Lett. 62 3691

Darzi S J and Mahjoub A R 2009 J. Alloys Compd. 486 805

McCord A T and Saunder H F 1945 U.S Patent 2379019

Steinike U and Wallis B 1997 Cryst. Res. Technol. 32 187

Jain P K, Kumar D, Kumar A and Kaur D 2010 Opto. Mater. Adv. Mater. 4 299

Manik S K and Pradhan S K 2006 Physica E 33 69

Mrazek J, Spanhel L, Chadyron G and Matejec V 2010 J. Phys. Chem. C. 114 2843

Hou L, Hou Y D, Zhu M K, Tang J, Liu J B, Wang H and Yan H 2005 Mater. Lett. 59 197

Nolan N T, Seery M K and Pillai S C 2011 Chem. Mater. 23 1496

Chai Y L, Chang Y S, Chen G J and Hsiao Y J 2008 Mater. Res. Bull. 43 1066

Wang C L, Hwang W S, Chang K M, Ko H H, Hisn C S, Huang H H and Wang M C 2011 Int. J. Mol. Sci. 12 935

Lee Y C and Chen P S 2013 Thin Solid Films. 531 222

Ramirez E G, Chaparro M M and Angel O Z 2010 Appl. Phys. A. 108 291

Phani A R, Passacantando M and Santucci S 2007 J. Phys. Chem. Solids. 68 317

Liu X 2012 Mater. Lett. 80 69

Liu Z, Zhou D, Gong S and Li H 2009 J. Alloys Compd. 475 840

Kim H T, Kim S H, Nahm S and Byun J D 1999 J. Am. Ceram. Soc. 82 3043

Cassaignon S, Koelsch M and Jolivet J P 2007 J. Phys. Chem. Solids. 68 695

Svehla G 1979 In Vogel’s Text book of macro and semimicro Qualitative Inorganic Analysis 5 th edition (London and New York: Longman) p 272 and 532

Zhong S L, Xu R, Wang L, Li Y and Zhang L F 2011 Mater. Res. Bull. 46 2385

Chamberland B L and Silverman S 1979 J. Less. Common. Met. 65 P41

Yuan Z, Huang F, Sun J and Zhou Y 2002 Chem. Lett. 31 408

Sharma Y, Sharma N, Rao G V S and Chowdari B V R 2009 J. Power Sources 192 627

Lu W and Schmidt H 2005 J. Eur. Ceram. Soc. 25 919

Yang J and Swisher J H 1996 Mater. Charact. 37 153

Wang C T and Lin J C2008 Appl. Surf. Sci. 254 4500

Yamaguchi O, Morimi M, Kawabata H and Shimizu K 1987 J. Am. Ceram. Soc. 70 C-97

Li G, Li L, Goates J B and Woodfield B F 2009 J. Am. Chem. Soc. 127 8659

Zheng M, Xing X., Deng J, Li L, Zhao J, Qiao L and Fang C 2007 J. Alloys Compd. 456 353

Wang L, Kang H, Xue D and Liu C 2009 J. Cryst. Growth. 311 611

Jeong T S, Han M S and Youn C J 2004 J. Appl. Phys. 96 175

Wang Z, Saxena S K and Zha C S 2002 Phys. Review B. 66 024103

Krylova G, Brioude A, Girard S A, Mrazek J and Spanhel L 2010 Phys. Chem. Chem. Phys. 12 15101

Huo Y and Hu Y H 2012 Ind. Eng. Chem. Res. 51 1083

Shi L and Lin H 2011 Langmuir 27 3977

Acknowledgments

The authors thank VIT-SIF for thermal analysis, powder XRD, FT-IR and DRS, and Dr. R.P. Vijayalakshmi, Sri Venkateswara University, Tirupati for Raman spectral data. One of the authors, B. Lokesh thanks VIT University for providing financial support to carry out the present work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

BUDIGI, L., NASINA, M.R., SHAIK, K. et al. Structural and optical properties of zinc titanates synthesized by precipitation method. J Chem Sci 127, 509–518 (2015). https://doi.org/10.1007/s12039-015-0802-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12039-015-0802-5