Abstract

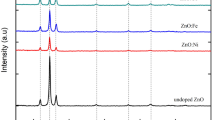

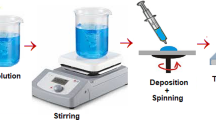

CuO films and ZnO/CuO heterostructured nanocomposite films were synthesized by a series of chemical reactions at different pH values based on the hydrothermal and SILAR (successive ionic layer adsorption and reaction) methods. The ultimate purpose of this work is to explore the impacts of solution pH value and ZnO-based heterostructure on the structural, optical and electrical features of CuO films using X-ray diffraction (XRD), Raman spectroscopy, scanning electron microscopy (SEM), energy-dispersive X-ray analysis (EDX), transmittance spectrum, current–voltage (I–V) measurements and capacitance–conductance (C–G) measurements in 300–600 K temperature range and 20 Hz–1.5 MHz frequency range. XRD analysis revealed that the crystallite size and strain lattice parameters decrease with the increase in pH value without affecting the crystalline structure of the synthesized films. SEM images revealed the regular growth of ZnO structure without any deterioration in the CuO substrate layer, where an increase in the thickness of the formed rods was observed with the increase in reaction pH value. Transmittance dropped greatly with the formation of heterojunction from about 40% (for CuO) to about 1% (for ZnO/CuO) in the visible range followed by a crystallite size-induced change in bandgap from 2.29 to 2.32 eV (for CuO) and from 2.03 to 2.11 eV (for ZnO/CuO). The increase in pH from 11.0 to 11.2 increased the room-temperature resistance of ZnO/CuO composites from 377 to 474 MΩ, the ideality factor from 4.41 to 4.68 and the barrier height from 0.74 to 0.83 eV. It can be deduced that reaction pH value is an important synthesis parameter that can tune the structural, morphological, optical and electrical properties of ZnO/CuO nanocomposite films for advanced industrial or technological implementations by controlling the nucleation and crystal growth rates during chemical synthesis processes.

Similar content being viewed by others

References

Morales-Mendoza J E and Paraguay-Delgado F 2021 Mater. Lett. 291 129494

Mohamed R M and Ismail A A 2021 Ceram. Int. 47 9659

Oliveira M C, Fonseca V S, Andrade Neto N F, Ribeiro R A P, Longo E, de Lazaro S R et al 2020 Ceram. Int. 46 9446

Velayi E and Norouzbeigi R 2019 Ceram. Int. 45 16864

Mahajan P, Singh A and Arya S 2020 J. Alloys Compd. 814 152292

Karaduman Er I, Çağırtekin A O, Çorlu T, Yildirim M A, Ateş A and Acar S 2019 Bull. Mater. Sci. 42 32

Terasako T, Murakami T, Hyodou A and Shirakata S 2015 Sol. Energy Mater. Sol. Cells 132 74

Abraham N and Aseena S 2021 Mater. Today Proc. 43 3698

Qin C, Wang Y, Gong Y, Zhang Z and Cao J 2019 J. Alloys Compd. 770 972

Hong K S, Kim J W, Bae J S, Hong T E, Jeong E D, Jin J S et al 2017 Phys. B: Condens. Matter 504 103

Soltabayev B, Çağırtekin A O, Mentbayeva A, Yıldırım M A and Acar S 2021 Thin Solid Films 734 138846

Kale S S, Mane R S, Chung H, Yoon M Y, Lokhande C D and Han S H 2006 Appl. Surf. Sci. 253 421

Shinde R S, Khairnar S D, Patil M R, Adole V A, Koli P B and Deshmane V V 2022 J. Inorg. Organomet. Polym. Mater. 62

Nami M, Sheibani S and Rashchi F 2021 Mater. Sci. Semicond. Process. 135 106083

Zayyoun N, Bahmad L, Laânab L and Jaber B 2016 Appl. Phys. A 122 488

Çayır Taşdemirci T 2020 Electron. Mater. Lett. 16 239

Karaduman Er I, Yıldız İ A, Bayraktar T, Acar S and Ateş A 2021 J. Mater. Sci. Mater. Electron. 32 8122

Abdulrahman A F, Ahmed S M, Hamad S M, Almessiere M A, Ahmed N M and Sajadi S M 2021 Chin. J. Phys. 71 175

Yüksel M, Pennings J R, Bayansal F and Yeow J T W 2020 Phys. B Condens. Matter 599 412578

Daoudi O, Qachaou Y, Raidou A, Nouneh K, Lharch M and Fahoume M 2019 Superlattices Microstruct. 127 93

Mageshwari K and Sathyamoorthy R 2013 Mater. Sci. Semicond. Process. 16 337

Bayansal F, Şahin B, Yüksel M, Biyikli N, Çetinkara H A and Güder H S 2013 J. Alloys Compd. 566 78

Gençyılmaz O and Taşköprü T 2017 J. Alloys Compd. 695 1205

Dinc S, Şahin B and Kaya T 2020 Mater. Sci. Semicond. Process. 105 104698

Ravi Dhas C, Alexander D, Jennifer Christy A, Jeyadheepan K, Moses Ezhil Raj A et al 2014 Asian J. Appl. Sci. 7 671

Ozutok F, Karaduman I, Demiri S and Acar S 2018 J. Electron. Mater. 47 2648

Altun B, Karaduman Er I, Çağırtekin A O, Ajjaq A, Sarf F and Acar S 2021 Appl. Phys. A 127 687

Rai R, Triloki T and Singh B K 2016 Appl. Phys. A 122 774

Altun B, Ajjaq A, Çağırtekin A O, Karaduman Er I, Sarf F and Acar S 2021 Ceram. Int. 47 27251

Şahin B and Kaya T 2021 Mater. Sci. Semicond. Process. 121 105428

Arandhara G, Bora J and Saikia P K 2020 Mater. Chem. Phys. 241 122277

Hussein Ahmed S, Bakiro M and Alzamly A 2019 Nano-Struct. Nano-Objects 20 100400

Visalakshi S, Kannan R, Valanarasu S, Kathalingam A and Rajashabala S 2016 Mater. Res. Innov. 21 146

Daira R, Kabir A, Boudjema B and Sedrati C 2020 Solid State Sci. 104 106254

Shariffudin S, Khalid S S, Sahat N M, Sarah M S P and Hashim H 2015 IOP Conf. Ser. Mater. Sci. Eng. 99 012007

Chvostová D, Dejneka A, Hubička Z, Churpita A, Bykov P, Jastrabík L et al 2011 Phys. Status Solidi 208 2140

Karaduman Er I, Çağırtekin A O, Ajjaq A, Yıldırım M A, Ateş A and Acar S 2021 J. Mater. Sci. Mater. Electron. 32 13594

Bodade A B, Taiwade M A and Chaudhari G N 2017 J. Appl. Pharm. Sci. 5 30

Goraya N and Singh S 2016 MATEC Web Conf. 57 01007

Zoolfakar A S, Abdul Rani R, Morfa A J, O’Mullane A P and Kalantar-Zadeh K 2014 J. Mater. Chem. C 2 5247

Rashad M, Rüsing M, Berth G, Lischka K and Pawlis A 2013 J. Nanomater. 714853

Sriyutha Murthy P, Venugopalan V P, Arunya D D, Dhara S, Pandiyan R and Tyagi A K 2011 Int. Conf. Nanosci. Eng. Technol. 580

Çağırtekin A O, Ajjaq A, Barin Ö and Acar S 2021 Phys. Scr. 96 115807

Kaphle A, Echeverria E, Mcllroy D N and Hari P 2020 RSC Adv. 10 7839

Attallah M A, Elrasasi T Y, Shash N M, El-Shaarawy M G, El-Tantawy F and El-Shamy A G 2021 Mater. Sci. Semicond. Process. 126 105653

Gupta R K, Ghosh K and Kahol P K 2010 Physica E 42 1509

Kanani M V, Dhruv D, Rathod H K, Rathod K N, Rajyaguru B, Joshi A D et al 2019 Scr. Mater. 165 25

Karaduman Er I, Çağırtekin A O, Artuç M and Acar S 2021 J. Mater. Sci. Mater. Electron. 32 1677

Polat O, Coskun M, Coskun F M, Zlamal J, Durmus Z, Caglar M et al 2020 Mater. Res. Bull. 124 110759

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Er, I.K., Ajjaq, A., Ateş, A. et al. Effect of reaction pH on the microstructural, optical and electrical behaviour of ZnO/CuO heterostructured nanocomposite films. Bull Mater Sci 45, 212 (2022). https://doi.org/10.1007/s12034-022-02803-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-022-02803-4