Abstract

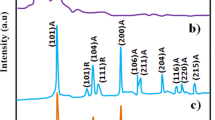

This paper presents the humidity sensing properties of surface-modified polyaniline (PAni). In this study, the impedance response and dielectric properties of pure- and doped-PAni have been investigated as a function of relative humidity (RH%) and frequency. PAni and PAni/Mn composite samples are synthesized by one-step interfacial polymerization process. The structural properties and surface morphologies of the prepared materials have been characterized by X-ray diffraction (XRD) and field emission scanning electron microscopy (FESEM), respectively. XRD confirms the formation of PAni and it shows semi-crystalline behaviour. FESEM shows granular, porous and well-distributed structure. It has been observed that the porosity and nanogranular structure increased with increasing doping percentage. Here, we observe that porous and granular structure of Mn-doped PAni shows better response and recovery time (\({\sim }28\hbox { s}\)) and decreases in electrical impedance. Dielectric constants, dielectric loss and AC conductivity have also been discussed with variations in frequency and relative humidity.

Similar content being viewed by others

References

Malenahalli H N, Nanjanagudu G G and Yoon-Bo S 2017 Appl. Mater. Today 9 419

Stefan C, Anna M and Marian Z 2018 Polym. Test. 67 342

Toshiaki O 2012 Int. J. Corros., Article ID 915090 7

Deshpande N G, Gudage Y G, Ramphal S, Vyas J C, Kim J B and Lee Y P 2009 Sens. Actuators B Chem. 138 76

Sikarwar S and Yadav B C 2015 Sens. Actuators A Phys. 233 54

Blank T A, Eksperiandova L P and Belikov K N 2016 Sens. Actuators B Chem. 228 416

Alwis L, Sun T and Grattan K T V 2013 Measurement 46 4052

Garcia L R and Lunadei L 2011 Comput. Electron. Agr. 79 42

Swanson A J, Raymond S G, Janssens S, Breukers R D, Bhuiyan M D H, Lovell-Smith J W et al 2016 Sens. Actuators A Phys. 249 217

Das R, Pattanayak A J and Sarat K S 2018 Polym. Nanocomposit. Energy Environ. Appl. p 205, chap 7. https://doi.org/10.1016/B978-0-08-102262-7.00007-6

Nambiar S and Yeow John T W 2011 Biosens. Bioelectron. 26 1825

Jong M M, Neeta T, Khalil K H, Rajendra N G and Yoon B S 2018 Biosens. Bioelectron. 102 540

Ramya R, Sivasubramanian R and Sangaranarayanan M V 2013 Electrochim. Acta 101 109

Kuilla T, Bhadra S, Yao D, Kim N H, Bose S and Lee J H 2010 Prog. Polym. Sci. 35 1350

Yang L and Mujie Y 2012 Sens. Actuators B Chem. 161 967

Milind V K, Sanjay K A, Sonali D N, Jalindar D A and Bharat B K 2013 Sens. Actuators B Chem. 178 140

Ilaria F, Iole V, Cesare C and Maria V R 2015 Sens. Actuators B Chem. 220 534

Mehrnaz J, Amir H N and Mehdi N 2014 Adv. Polym. Tech. 33 1

Ramaprasad A T and Vijayalakshmi R 2010 Sens. Actuators B Chem. 148 117

Song E and Choi J-W 2013 Nanomaterials 3 498

Liming W, Qin Y, Hui B, Fuqiang H, Qun W and Lidong C 2015 J. Mater. Chem. A 15 7086

Vineet K S, Poonam Y, Raghvendra S Y, Priya M and Avinash C P 2012 Nanoscale 4 3886

Benson J, Kovalenko I, Boukhalfa S, Lashmore D, Sanghadasa M and Yushin G 2013 Adv. Mater. 25 6625

Qingqing C, Meixiang N and Ying G 2018 Sens. Actuators B Chem. 254 30

Rachna R, Sheetal C, Nidhi C, Tulika D and Pundir C S 2012 Int. J. Biol. Macromol. 50 112

Nanjundan A K, Hyun J C, Yeon R S, Dong W C, Liming D and Jong B B 2012 ACS Nano 6 1715

Jain S, Chakane S, Samui A B, Krishnamurthy V N and Bhoraskar S V 2003 Sens. Actuators B96 124

Parvatikar N, Jain S, Khasim S, Revansiddappa M, Bhoraskar S V and Ambika Prasad M V N 2006 Sens. Actuators B114 599

Pandey S 2016 J. Sci. Adv. Mater. Devices1 431

McGovern S T, Spinks G M and Wallace G G 2005 Sens. Actuators B Chem. 107 657

Aussawasathien D, Dong J H and Dai L 2005 Synth. Met. 154 37

Pouget J P 1991 Macromolecules 24 779

Borah R, Banerjee S and Kumar A 2014 Synth. Met. 197 225

Gupta K, Jana P C and Meikap A K 2010 Synth. Met. 160 1566

Xingbin Y, Zhixin T, Jiangtao C and Qunji X 2011 Nanoscale 3 212

Chiou N R and Epstein A J 2005 Adv. Mater. 17 1679

Jozefowicz M E, Laversanne R, Javadi H H S, Epstein A J, Pouget J P, Tang X et al 1989 Phys. Rev. B 39 12958

Cosmin L, Zujovic Z D and Travas-Sejdic J 2009 Macromol. Rapid Commun. 30 1663

Jiaxing Huang and Richard B Kaner 2004 J. Am. Chem. Soc. 126 851

Shishov M A, Moshnikov V A and Sapurina I Y 2013 Chem. Pap. 67 909

Zhou Y K, He B L, Zhou W J, Huang J, Li X H, Wu B et al 2004 Electrochim. Acta 49 257

Jaroslav S, Irina S, Miroslava T and Elena N K 2008 Macromolecules 41 3530

Jain S, Chakane S, Samui A B, Krishnamurthy V N and Bhoraskar S V 2003 Sens. Actuators B Chem. 96 124

Fuke M V, Kanitkar P, Kulkarni M, Kale B B and Aiyer R C 2010 Talanta 81 320

Tuccimei P, Moroni M and Norcia D 2006 Appl. Radiat. Isot. 64 254

Khalil J H 2014 Appl. Modern Sci. 8 124

Sui G, Jana S, Zhong W H, Fuqua M A and Ulven C A 2008 Acta Mater. 56 2381

Prem Nazeer K, Jacob S A, Thamilselvan M, Mangalaraj D, Narayandass S K and Junsin Yi 2004 Polym. Int. 53 898

Choudhury A 2009 Sens. Actuators B Chem. 138 318

Jain A, Sagar P and Mehra R M 2007 Mater. Sci.—Poland 25 237

Imene B A 2015 J. Nanomater. Article ID 516902

Acknowledgements

We are grateful to UP state government through the Centre of Excellence Scheme for providing XRD facility at the Department of Physics, University of Lucknow.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srivastava, D., Shukla, R.K. Impedance variation with different relative humidities of PAni/Mn nanofibres. Bull Mater Sci 43, 95 (2020). https://doi.org/10.1007/s12034-020-2063-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-2063-2