Abstract

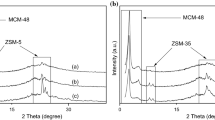

In this study, we propose the generation of micro/mesoporous zeolites with ZSM-11 structure by hydrothermal treatment using tetrabutylammonium hydroxide (TBAOH) as micropore structure directing agent and cetyltrimethylammonium bromide (CTAB) as mesotemplate. From many synthesis parameters evaluated (crystallization time, hydrothermal temperature, CTAB content), the type of base employed in the synthesis gel showed notorious influence in the structure, textural properties and morphology of the micro/mesoporous ZSM-11 zeolites. The samples were characterized by different techniques such as X-ray diffraction, nitrogen adsorption and desorption isotherms, Brunauer–Emmett–Teller surface area, scanning electron microscope, ICP-AES and 27Al MAS NMR. The characterization results revealed that the crystallization time, CTAB content and type of base (NaOH, KOH, Ca(OH)2 and NaCO3) played a dominant role in controlling the formation of both microporous and mesoporous structures. The base employed in the synthesis and its concentration showed important effects on the structure and textural properties of the composite materials. It was found that to obtain the best characteristics in terms of crystallinity and textural parameters, NaOH and KOH should be employed.

Similar content being viewed by others

References

Corma A 1997 Chem. Rev. 97 2373.

Davis M E 2002 Nature 417 813

Noor P, Khanmohammadi M, Roozbehani B, Yaripour F and Garmarudi A B 2018 J. Energy Chem. 27 582

Feliczak-Guzik A 2018 Microporous Mesoporous Mater. 259 33

Sazama P, Pastvova J, Kaucky D, Moravkova J, Rathousky J, Jakubec I et al 2018 J. Catal. 364 262

Feng R, Yan X, Hu X, Yan Z, Lin J, Li Z et al 2018 Catal. Commun. 109 1

Verboekend D, Mitchell S, Milina M, Groen J C and Pérez-Ramírez J 2011 J. Phys. Chem. C 115 14193

Ahmadpour J and Taghizadeh M 2016 Synth. React. Inorg. Met.-Org. Nano-Metal Chem. 46 1133

Tao Y, Kanoh H and Kaneko K 2003 J. Am. Chem. Soc. 125 6044

Schmidt I, Boisen A, Gustavsson E, Ståhl K, Pehrson S, Dahl S et al 2001 Chem. Mater. 13 4416

Janssen A H, Schmidt I, Jacobsen C J H, Koster A J and De Jong K P 2003 Microporous Mesoporous Mater. 65 59

Kustova M Y, Hasselriis P and Christensen C H 2004 Catal. Lett. 96 205

Zhu H, Liu Z, Wang Y, Kong D, Yuan X and Xie Z 2007 Chem. Mater. 20 1134

Peng P, Sun S Z, Liu Y X, Liu X M, Mintova S and Yan Z F 2018 J. Colloid Interface Sci. 529 283

Choi M, Cho H S, Srivastava R, Venkatesan C, Choi D H and Ryoo R 2006 Nat. Mater. 5 718

Wang L, Zhang Z, Yin C, Shan Z and Xiao F S 2010 Microporous Mesoporous Mater. 13 58

Wang H and Pinnavaia T J 2006 Angew. Chemie Int. Ed. 45 7603

Jiang J, Ji S, Duanmu C, Pan Y, Wu J, Wu M et al 2017 Particuology 33 55

Zhang M, Liu X and Yan Z 2016 Mater. Lett. 164 543

Sabarish R and Unnikrishnan G 2017 Powder Technol. 320 412

Sohrabnezhad S, Jafarzadeh A and Pourahmad A 2018 Mater. Lett. 212 16

Bernal Y P, Alvarado J, Juárez R L, Rojas M A M, de Vasconcelos E A, de Azevedo W M et al 2019 Optik 185 429

Chen H, Wang Y, Meng F, Sun C, Li H, Wang Z et al 2017 Microporous Mesoporous Mater. 244 301

Xue T, Liu H, Zhang Y, Wu H, Wu P and He M 2017 Microporous Mesoporous Mater. 242 190

Jiang Y, Wang Y, Zhao W, Huang J, Zhao Y, Yang G et al 2016 J. Taiwan. Inst. Chem. Eng. 61 234

Chen H L, Ding J and Wang Y M 2014 New J. Chem. 38 308

Chu P 1973 U.S. Patent No. 3,709,979, Washington, DC: U.S., Patent and Trademark Office

Sing K S 1985 Pure Appl. Chem. 57 603

Thommes M, Kaneko K, Neimark A V, Olivier J P, Rodriguez-Reinoso F, Rouquerol J et al 2015 Pure Appl. Chem. 87 1051

Klinowski J 1984 Prog. Nucl. Magn. Reson. Spectrosc. 16 237

Jiao J, Altwasser S, Wang W, Weitkamp J and Hunger M 2004 J. Phys. Chem. B 10 14305

Yu D K, Fu M L, Yuan Y H, Song Y B, Chen J Y and Fang Y W 2016 J. Fuel. Chem. Technol. 44 1363

Mintova S, Valtchev V and Kanev I 1993 Zeolites 13 102

Xu D, Feng J and Che S 2014 Dalton Trans. 43 3612

Leofanti G, Padovan M, Tozzola G and Venturelli B 1998 Catal. Today 41 207

Do M H, Wang T, Cheng D G, Chen F, Zhan X, Rioux R M et al 2014 Small 10 4249

Burton A W and Zones S I 2007 Stud. Surf. Sci. Catal. 168 137

Dewaele N, Bodart P, Gabelica Z and Nagy J B 1985 Stud. Surf. Sci. Catal. 24 119

Juan R, Hernández S, Andrés J M and Ruiz C 2007 Fuel 86 1811

Garcia G, Cabrera S, Hedlund J and Mouzon J 2018 J. Cryst. Growth 489 36

Groen J C, Moulijn J A and Pérez-Ramírez J 2007 Ind. Eng. Chem. Res. 46 4193

Visser J H M 2018 Cement. Conc. Res. 105 18

Wijnen P W J G, Beelen T P M, De Haan J W, Van De Ven L J M and Van Santen R A 1990 Colloids Surf. 45 255

Emeis C A 1993 J. Catal. 141 347

Serrano D P, Escola J M and Pizarro P 2013 Chem. Soc. Rev. 42 4004

Acknowledgements

This study was supported by Ministerio de Ciencia y Tecnología de Córdoba (PIOdo 2018), Universidad Tecnológica Nacional (PID UTN 6562) and Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bonetto, L., Pierella, L.B. & Saux, C. Key parameters to improve zeolites hierarchization in direct synthesis. Bull Mater Sci 43, 288 (2020). https://doi.org/10.1007/s12034-020-02254-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-02254-9