Abstract

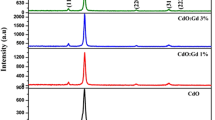

A perfume atomizer-assisted spray pyrolysis method was employed to fabricate undoped and neodymium (Nd)-doped cadmium oxide (CdO) thin films. X-ray diffraction results reveal that all the films are polycrystalline with a cubic structure with a preferential orientation along the (200) direction. Scherrer’s formula was used to calculate the crystallite size of Nd-doped CdO films. Energy dispersive spectroscopy results show that Cd, Nd and O elements are present in Nd-doped CdO thin films. The optical absorption of the doped films is increased along with increasing Nd-doping level. The prepared CdO thin films have a high absorption coefficient in the visible region and the optical band gap is decreased on increasing Nd doping content. The electrical carrier concentration (n) of the deposited films is increased with increasing Nd doping concentration. Photoconductivity studies of a nanostructured Al/Nd–n-CdO/p-Si/Al device showed a non-linear electric characteristics indicating diode-like behaviour. Prepared Nd:CdO films could increase the photo-sensing effect of this n-CdO/p-Si heterostructure. These Nd-doped CdO thin films may open a new avenue for photodiode application in near future.

Similar content being viewed by others

References

Ito N, Sato Y, Song P K, Kaijio A, Inoue K and Shigesato Y 2006 Thin Solid Films 496 99

Lim J T, Jeong C H, Vozny A, Lee J H, Kim M S and Yeom G Y 2007 Surf. Coat. Technol. 201 5358

Navamathavan R, Choi C K and Park S J 2009 J. Alloys Compd. 475 889

Ilican S, Caglar Y, Caglar M, Kundakci M and Ates A 2009 Int. J. Hydrog. Energy 34 5201

Deva Arun Kumar K, Valanarasu S, Jeyadheepan K, Hyun-Seok K and Dhanasekaran V 2018 J. Mater. Sci.: Mater. Electron. 29 3648

Deva Arun Kumar K, Ganesh V, Shkir M, Alfalfa S and Valanarasu V 2018 J. Mater. Sci. Mater. Electron. 29 887

Cruz J S, Delgado G T, Perez R C, Romero C I Z and Angel O Z 2007 Thin Solid Films 515 5381

Vigil O, Cruz F, Morales-Acevedo A, Contreras-puente G, Vaillant L and Santana G 2001 Mater. Chem. Phys. 68 249

Subramanyam T K, Uthanna S and Naidu B S 1998 Mater. Lett. 35 214

Chu T L and Chu S S 1963 J. Electrochem. Soc. 110 548

Zhao Z, Morel D L and Ferekides C S 2002 Thin Solid Films 413 203

Gutierrez L R L, Romero J J C, Tapia J M P, Calva E B, Flores J C M and Lopez M O 2006 Mater. Lett. 60 3866

Gupta R K, Ghosh K, Patel R, Mishra S R and Kahol P K 2008 Mater. Lett. 62 4103

Yagi I, Hagiwara Y, Murakami K and Kaneko S 1993 J. Mater. Res. 81 481

Joseph Edison D, Nirmala W, Deva Arun Kumar K, Valanarasu S, Ganesh V, Shkir M et al 2017 Physica B 523 31

Murakami K, Yagi I and Kaneko S 1996 J. Am. Ceram. Soc. 79 2557

Kaneko S, Yagi I, Kosugi T and Murakami K 1998 in: A P Tomsia and A M Glaeser (eds) Ceramic microstructures (Boston, MA: Springer)

Gupta R K, Ghosh K, Patel R and Kahol P K 2011 J. Alloys Compd. 509 4146

Gupta R K, Serbetci Z and Yakuphanoglu F 2012 J. Alloys Compd. 515 96

Deokate R J, Pawar S M, Moholkar A V, Sawant V S, Pawar C A, Bhosale C H et al 2008 Appl. Surf. Sci. 254 2187

Herednis D P and Gauckler L J 2005 J. Electroceram. 14 103

Mariappan R, Ragavendar M and Ponnuswamy V 2011 J. Alloys Compd. 509 7337

Shkir M, Ganesh V, AlFaify S, Yahia I S and Zahran H Y 2018 J. Mater. Sci.: Mater. Electron. 29 6446

Valanarasu S, Dhanasekaran V, Karunakaran M, Vijayan T A, Chandramohan R and Maalingam T 2014 J. Mater. Sci.: Mater. Electron. 25 3846

Deva Arun Kumar K, Valanarasu S, Tamilnayagam V and Amalraj L 2017 J. Mater. Sci.: Mater. Electron. 28 14209

Cusco R, Ibanez J, Domenech-Amador N, Artus L, Zuniga-Perez J and Munoz Sanjose V 2010 J. Appl. Phys. 107 063519

Oliva R, Ibanez J, Artus L, Cusco R, Zuniga-Perez J and Muno Sanjose V 2013 J. Appl. Phys. 113 053514

Sahin B 2013 Sci. World J. 2013 1

Thema F T, Beukes P, Gurib-Fakim A and Maaza M 2015 J. Alloys Compd. 646 1043

Knaepen E, Mullens J, Yperman J and Poucke L C V 1996 Thermochim. Acta 284 213

Thirumoorthi M and Thomas J P 2015 J. Asian Ceram. Soc. 4 39

Shkir M and AlFaify S 2017 Sci. Rep. 7 16091

Shkir M, Ganesh V, AlFaify S and Yahia I S 2017 J. Mater. Sci.: Mater. Electron. 28 10573

Shkir M, Yahia I S, Ganesh V, Algarni H and AlFaify S 2016 Mater. Lett. 176 135

Dakhel A A 2009 J. Alloys Compd. 475 51

Ravikumar M, Ganesh V, Shkir M, Chandramohan R, Deva Arun Kumar K, Valanarasu S et al 2018 J. Mol. Struct. 1160 311

Dakhel A A 2009 Sol. Energy 83 934

Kawamura K, Maekawa K, Yanagi H, Hirano M and Hosono H 2003 Thin Solid Films 445 182

Ueda N, Maeda H, Hosono H and Kawazoe H 1998 J. Appl. Phys. 84 6174

Xu Y and Schoonen M A A 2000 Am. Mineral. 85 543

Nese K, Sertap Kavasoglu A and Sener O 2009 J. Phys. Chem. Solids 70 521

Sankarasubramanian K, Soundarrajan P, Sethuraman K, Ramesh Babu R and Ramamurthi K 2014 Superlattices Microstruct. 69 29

Sui Y R, Cao Y, Li X F, Yue Y G, Yao B, Li X Y et al 2015 Ceram. Int. 41 587

Dingle R 1969 Phys. Rev. Lett. 23 579

Dong W and Zhu C 2003 Opt. Mater. 22 227

Jun Kuo T, Micheal Z and Huang H 2006 J. Phys. Chem. B 110 13717

Rhoderick E H and Williams R H 1988 Metal-semiconductor contacts 2nd edn (Oxford: Clarendon)

Ugurel S A E, Serifoglu K and Turut A 2008 Microelectron. Eng. 85 2299

Chen P, Ma X and Yang D 2007 J. Appl. Phys. 101 053103

Ravikumar M, Chandramohan R, Deva Arun Kumar K and Valanarasu S 2018 J. Sol-Gel Sci. Technol. 85 31

Naderi N and Hashim M R 2013 J. Alloys Compd. 552 356

Acknowledgements

We would like to express our gratitude to King Khalid University, Saudi Arabia for providing administrative and technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravikumar, M., Chandramohan, R., Kumar, K.D.A. et al. Effect of Nd doping on structural and opto-electronic properties of CdO thin films fabricated by a perfume atomizer spray method. Bull Mater Sci 42, 8 (2019). https://doi.org/10.1007/s12034-018-1688-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-018-1688-x