Abstract

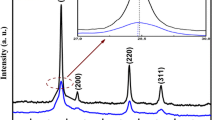

Currently, copper chromium oxide crystallizing in delafossite structure attracts huge research interest due to its versatile applications arising from its layered structure. In this work, delafossite CuCrO2 was synthesized by sol–gel method from their respective hydrated nitrate salts with citric acid as a chelating agent. The phase formation temperature was found to be between 750 and 775∘C. At 750∘C, the partial formation of delafossite CuCrO2 spheres with particle size in nano-regime was observed in the midst of platelets of spinel CuCr2O4. A green coloured powder with particle size 125–350 nm exhibiting distorted spheres was obtained at 775∘C. The increase in temperature has a profound impact on the particle size, morphology and the optical properties of CuCrO2. The X-ray powder diffraction studies revealed the formation of 3R-CuCrO2 phase (rhombohedral, space group R-3m) as a major product in the temperature range 775–1000∘C. The unit cell parameters were found to be a = b = 2.9711 Å and c = 17.0723 Å at 1000∘C. Scanning electron micrographs illustrated the different morphologies from spheres to hexagonal form via distorted spheres and cubes. The UV–Vis diffuse reflectance spectra measured for the powders exhibited semiconductor characteristics with an interesting size-related and temperature-dependent bandgap.

Similar content being viewed by others

References

Marquardt M A, Ashmore N A and Cann D P 2006 Thin Solid Films 496 146

Amrute A P, Larrazabal G O, Mondelli C and Ramirez J P 2013 Angew. Chem. Int. Ed. 52 9772

Zhou S, Fang X, Deng Z, Li D, Dong W, Tao R, Meng G and Wang T 2009 Sensor Actuat. B 143 119

Kameoka S, Okada M and Tsai A P 2008 Catal. Lett. 120 252

Meng Q, Lu S, Lu S and Xiang Y 2012 J. Sol–Gel Sci. Technol. 63 1

Powar S, Xiong D, Daeneke T, Ma M T, Gupta A, Lee G, Makuta S, Tachibana Y, Chen W, Spiccia L, Cheng Y B, Goetz G, Baeuerle P and Bach U 2014 J. Phys. Chem. C 118 16375

Xiong D, Zhang W, Zeng X, Xu Z, Chen W, Cui J, Wang M, Sun L and Cheng Y B 2013 ChemSusChem 6 1432

Shannon R D, Rogers D B and Prewitt C T 1971 Inorg. Chem. 10 713

Ketir W, Saadi S and Trari M 2012 J. Solid State Eletrochem. 16 213

Amrute A P, Lodziana Z, Mondelli C, Krumeich F and Ramirez J P 2014 Chem. Mater. 25 4423

Sheets W C, Mugnier E, Barnabe A, Marks T J and Poeppelmeier K R 2006 Chem. Mater. 18 7

Zhou S, Fang X, Deng Z, Li D, Dong W, Tao R, Meng G, Wang T and Zhu X 2008 J. Cryst. Growth 310 5375

Miclau M, Ursu D, Kumar S and Grozescu I 2012 J. Nanopart. Res. 14 1110

Chiu T W, Yu B S, Wang Y R, Chen K T and Lin Y T 2011 J. Alloys Compd. 509 2933

Deng Z, Zhu X, Tao R, Dong W and Fang X 2007 Mater. Lett. 61 686

Kumar S, Marinela S, Miclau M and Martin C 2012 Mater. Lett. 70 40

Okuda T, Jufuku N, Hidaka S and Terada N 2005 Phy. Rev. B 72 144403(1)

Poienar M, Hardy V, Kundys B, Singh K, Maignan A, Damay F and Martin C 2012 J. Solid State Chem. 185 56

Goetzendoerfer S, Polenzky C, Ulrich S and Loebmann P 2009 Thin Solid Films 518 1153

Kawazoe H, Yasukawa M, Hyodo H, Kurita M, Yanagi H and Hosono H 1997 Nature 389 939

Nagarajan R, Draeske A D, Sleight A W and Tate J 2001 J. Appl. Phys. 89 8022

Benko F A and Koffyberg F P 1986 Mater. Res. Bull. 21 753

Mahapatra S and Shivasankar S A 2003 Chem. Vap. Deposition 9 238

Li D, Fang X D, Deng Z H, Zhou S, Tao R H, Dong W W, Wang T, Zhao Y P, Meng G and Zhu X B 2007 J. Phys. D : Appl. Phys. 40 4910

Scanlon D O and Watson G W 2011 J. Mater. Chem. 21 3655

Bywalez R, Goetzendoerfer S and Loebmann P 2010 J. Mater. Chem. 20 6562

Li D, Fang X, Zhao A, Deng Z, Dong W and Tao R 2010 Vacuum 84 851

Xiong D, Zeng X, Zhang W, Chen W, Xu X, Wang M and Cheng Y B 2012 J. Mater. Chem. 22 24760

Ursu D and Miclau M 2014 J. Nanopart. Res. 16 2160

Srinivasan R, Chavillon B, Dossier-Brochard C, Cario L, Paris M, Gautron E, Deniard P, Odobel F and Jobic S 2008 J. Mater. Chem. 18 5647

Chavillon B, Cario L, Dossier-Brochard C, Srinivasan R, Le Pleux L, Pellegrin Y, Blart E, Odobel F and Jobic S 2010 Phys. Status Solidi A 207 1642

Goetzendoerfer S, Bywalez R and Loebmann P 2009 J. Sol–Gel Sci. Technol. 52 113

Ahmad A, Jagadale T, Dhas V, Khan S, Patil S, Pasricha R, Ravi V and Ogale S B 2007 Adv. Mater. 19 3295

Srinivasan R and Bolloju S 2014 AIP Conf. Proc. 1576 205

Singh K A and Pathak L C 2007 Ceram. Int. 33 1463

Saadi S, Bouguelia A and Trari M 2006 Sol. Energy 80 272

Zeghbroeck B V 2011 Principle of semiconductor devices, http://ecee. colorado.edu/~bart/book/book/contents.htm (University of Colorado)

Acknowledgements

Department of Science and Technology (DST SERB) is acknowledged for funding through the FASTTRACK scheme (No. SR/FT/CS-024/2010). We wish to thank the Department of Physics, Alagappa University at Karaikudi, Centre for Nano Science and Technology, Karunya University at Coimbatore and University of Hyderabad for characterization facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

BOLLOJU, S., SRINIVASAN, R. Sub-micron-sized delafossite CuCrO2 with different morphologies synthesized by nitrate–citric acid sol–gel route. Bull Mater Sci 40, 195–199 (2017). https://doi.org/10.1007/s12034-016-1340-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-016-1340-6