Abstract

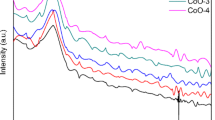

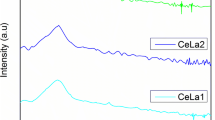

A small amount of nickel oxide is doped in bioglass®; system and it is replaced by silica. The use of 45S5 glass composition is one such material able to bond strongly to bone within 42 days. The 45S5 bioglass®; system develops a hydroxyl carbonate apatite (HCA) layer, which is chemically and crystallographically similar to mineral phase of bone. But it has low fracture toughness and mechanical weakness due to an amorphous glass network and it is not compatible for load-bearing applications. In the present work, the effect of addition of nickel oxide that annualizes the improvement in its mechanical strength and bioactivity is studied. Bioactivity of base glass and doped glass samples were tested through their HCA abilities by immersing them in simulated body fluid (SBF) for different days. The formation of HCA was confirmed by FTIR spectroscopy and pH measurement. Densities and mechanical properties of samples were also increased considerably by increasing the concentration of nickel oxide.

Similar content being viewed by others

References

Hench L L, Splinter R J, Allen W C and Greenlee T K 1971 J. Biomed. Mater. Res. 5 117

Hench L L and Anderson O 1993 An introduction to bioceramic (Singapore: World Scientific) p 41

Zhong J P and Greenspan D C 1998 in Bioceramic 11 (ed.) R Z Legeros (Singapore: World Scientific) p. 415

Neo M, Kotani S, Fujita Y, Nakamura T and Yamamuro T 1992 J. Biomed. Mater. Res. 26 1419

Oonishi H, Hench L L, Wilson J, Sugihara E T., Matsuura M et al 2000, ibid 51 37

Ducheyne P and Qiu Q 1999 Biomaterials 20 2287

Hench L L 1991 J. Am. Ceram. Soc. 74 1487

Leonor I B, Sousa R A, Cunha A M, Reis R L, Zhong Z P and Greenspan D 2002 J. Mater. Sci. Mater. Med. 13 939

Cabal B, Malpartida F, Torrecillas R, Hoppe A, Boccaccini A R and Moya J S 2011 Adv. Eng. Mater. 13 B462

Padmanabhann S K, Gervaso F, Carrozzo M, Scalera F, Sannino A and Licciulli A 2013 Ceram. Int. 39 619

Vitale-Brovarone C, Nunzio S D, Bretcanu O and Vern E 2004 J. Mater. Sci. Mater. Med. 15 209

Martorana S, Fedele A, Mazzocchi M and Bellosi A 2009 Appl. Surf. Sci. 255 6679

Singh V K and Reddy B R 2012 Ceram. Int. 38 5333

Simon V, Lucacel R C, Titorencu I and Jinga V 2011 Key Eng. Mater. 1463 85

Soares P, Laurindo C A H, Torres R, Kuromoto N, Peitl O and Zanotto E 2012 Surf. Coat. Technol. 206 4601

Hench L L, Splinter R J, Allen W C and Greenlee T K 1971 J. Biomed. Mater. Res. Symp. (Part 1) 4 117

Hench L L 1991 J. Am. Ceram. Soc. 74 1487

Hench L L and Paschall H A 1974 J. Biomed. Mater. Res. Symp. (Part 1) 5 49

Hench L L 1997 Curr. Opin. Solid State Mater. Sci. 2 604

Castillo J, Yanes A C, Méndez-Ramos J, Velázquez J J and Rodríguez V D 2011 J. Sol–Gel Sci. Technol. 60 170

Assem E E 2005 J. Phys. D Appl. Phys. 38 942

Sanada T, Seto H, Morimoto Y, Yamamoto K, Wada N and Kojima K 2010 J. Sol–Gel Sci. Technol. 56 82

Ghasemzadeh M, Nemati A and Baghshahi S 2012 J. Eur. Ceram. Soc. 32 2989

Sampath Kumar A, Tripathi H, Vyas V K, Jain S, Suman S K, Rana P. and Singh S P 2015 Mater. Sci. Eng. C 49 549

Vyas V K, Sampath Kumar A, Prasad S, Singh S P and Ram P. 2015, Bull. Mater. Sci. 38 957

Azevedo M M, Jell G, O’Donnell M D, Law R V, Hill R G and Stevens M M 2010 J. Mater. Chem. 20 8854

Smith J M, Martin R A, Cuelloc G J and Newporta R J 2013 J. Mater. Chem. B 1 1296

Kokubo T and Takadama H 2006 Biomaterials 27 2907

Nayak J P, Kumar S and Bera J 2010 J. Non-Cryst. Solids 356 1447

Cerrutia M, Greenspanb D and Powers K 2005 Biomaterials 26 1665

Hench L L 1998 J. Am. Ceram. Soc. 81 1705

Mastelaro V R, Zanotto E D, Lequeux N and Cortes R 2000 J. Non-Cryst. Solids 262 191

Ducheyne P and Qiu Q 1999 Biomaterials 20 2287

Hench L L 1998 J. Am. Ceram. Soc. 81 1705

Kokubo T, Kim H -M and Kawashita M 2003 Biomaterials 24 2161

Rehman I, Karsh M, Hench L L and Bonfield W 2000 , J. Biomed. Mater. Res. 50 97

Mastelaro V R, Zanotto E D, Lequeux N and Cortes R 2000 J. Non-Cryst. Solids 262 191

Ducheyne P and Qiu Q 1999 Biomaterials 20 2287

Srivastava A K, Pyare R and Singh S P 2012 Int. J. Sci. Eng. Res. 3 1

Srivastava A K and Pyare R 2012 Int. J. Sci. Technol. Res. 1 28

Acknowledgement

We gratefully acknowledge the HOD, Department of Ceramic Engineering, Indian Institute of Technology (Banaras Hindu University), Varanasi, India and the honourable Director of Indian Institute of Technology (Banaras Hindu University), Varanasi, India, for providing necessary facilities for the present work. The author, Vikash Kumar Vyas is also very much grateful to the University Grants Commission, New Delhi, India (RGNF-SC-UTT-2012-13-25709) for providing the Rajiv Gandhi National Fellowship for the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

VYAS, V.K., KUMAR, A.S., SINGH, S.P. et al. Effect of nickel oxide substitution on bioactivity and mechanical properties of bioactive glass. Bull Mater Sci 39, 1355–1361 (2016). https://doi.org/10.1007/s12034-016-1242-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-016-1242-7