Abstract

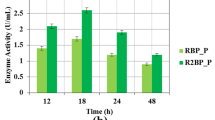

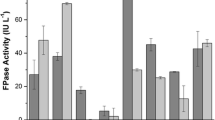

Solid wastes are the major contributors in global environmental pollution and their management is the need of urgency towards development of sustainable world. In the present work, solid waste of potato peels has been used as feedstock for fermentation of bacterial cellulase production and substrate for enzymatic hydrolysis via this enzymes cocktail. Additionally, liquid extracts of pea pod and root of water hyacinth wastes have been used to complete nutritional requirements and moisture balance in SSF process during the course of enzyme production. At optimum feedstock concentration of 6.0 g PPW and 10:40 extract-based moisture ratio of WHR and Ppw, Bacillus sp. produced 15 U/gds FP in 18 h, whereas maximum 36 U/gds BGL and 42 U/gds EG have been recorded in 24 h of SSF. Temperature 35 °C and pH 5.5 were optimum for enzyme production while the produced enzyme was thermally stable upto 30 h at 35 °C with 100% pH stability upto 14 h and 77% relative activity at 34 h. The optimized bacterial enzymes have been used for bioconversion of PPW biomass and 26 g/L glucose has been recorded at a hydrolytic temperature of 50 °C and pH 5.0. The study may have feasible promising scope in cellulosic biorefineries and waste management.

Similar content being viewed by others

References

Periyasamy, S., Karthik, V., Senthil Kumar, P., Isabel, J. B., Temesgen, T., Hunegnaw, B., Melese, B., & Mohamed, B. A., Vo D-VN (2022). Chemical, physical and biological methods to convert lignocellulosic waste into value-added products. A review. Environmental Chemistry Letters, 20(2), 1129–1152.

Ja’afar, Ja. N., & Shitu, A. (2022). Utilization of Lignocellulosic agro-waste as an alternative carbon source for industrial enzyme production. Waste management, processing and valorisation (pp. 221–233). Singapore: Springer Singapore.

Himanshu & Saini, J. K. (2022). Diversity and biotechnological importance of cellulolytic microorganisms from biodiversity hotspots. Microbial diversity in hotspots (pp. 207–230). Elsevier.

Fatima, A., Yasir, S., Khan, M. S., Manan, S., Ullah, M. W., & Ul-Islam, M. (2021). Plant extract-loaded bacterial cellulose composite membrane for potential biomedical applications. Journal of Bioresources and Bioproducts, 6(1), 26–32.

Xia, Z., Li, J., Zhang, J., Zhang, X., Zheng, X., & Zhang, J. (2020). Processing and valorization of cellulose, lignin and lignocellulose using ionic liquids. Journal of Bioresources and Bioproducts, 5(2), 79–95.

Jayasekara, S., & Ratnayake, R. (2019). Microbial cellulases: An overview and applications. Cellulose, 22, 92.

Ben Taher, I., Bennour, H., Fickers, P., & Hassouna, M. (2017). Valorization of potato peels residues on cellulase production using a mixed culture of Aspergillus niger ATCC 16404 and Trichoderma reesei DSMZ 970. Waste and biomass valorization, 8, 183–192.

Ben Bakrim, W., Ezzariai, A., Karouach, F., Sobeh, M., Kibret, M., Hafidi, M., Kouisni, L., & Yasri, A. (2022). Eichhornia crassipes (Mart.) Solms: A comprehensive review of its chemical composition, traditional use, and value-added products. Frontiers in Pharmacology, 13, 842511.

Sirohi, R., Singh, A., Tarafdar, A., Shahi, N. C., Verma, A. K., & Kushwaha, A. (2019). Cellulase production from pre-treated pea hulls using Trichoderma reesei under submerged fermentation. Waste and Biomass Valorization, 10, 2651–2659.

Srivastava, N., Srivastava, M., Gupta, V. K., Ramteke, P. W., & Mishra, P. K. (2018). A novel strategy to enhance biohydrogen production using graphene oxide treated thermostable crude cellulase and sugarcane bagasse hydrolyzate under co-culture system. Bioresource Technology, 270, 337–345. https://doi.org/10.1016/j.biortech.2018.09.038

Ghose, T. K. (1987). Measurements of cellulase activities, pure and applied chemistry (Vol. 59, No. 2, pp. 257–268). https://doi.org/10.1351/pac198759020257

Kubicek, C. P. (1982). β-Glucosidase excretion by Trichoderma pseudokoningii: correlation with cell wall bound β-1.3-glucanase activities. Archives of Microbiology, 132, 349–354.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31(3), 426–428.

Bradford, M. M. (1976). A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72(1–2), 248–254.

Helkar, P. B., Sahoo, A. K., & Patil, N. (2016). Review: Food industry by-products used as a functional food ingredients. International Journal of Waste Resources, 6(3), 1–6.

Salim, N. S. M., Singh, A., & Raghavan, V. (2017). Potential utilization of fruit and vegetable wastes for food through drying or extraction techniques. Nov Technology Nutrition Food Science, 1, 1–12.

dos Santos, T. C., Gomes, D. P. P., Bonomo, R. C. F., & Franco, M. (2012). Optimisation of solid state fermentation of potato peel for the production of cellulolytic enzymes. Food Chemistry, 133(4), 1299–1304.

Atinuke, O. A., & Samuel, F. (2015). Production of bacterial amylases and cellulases using sweet potato (Ipomoea batatas.(L.) Lam.) peels. African Journal of Biochemistry Research, 9(9), 104–109.

Ng SM, Tey LH, Leong SY, Ng SA: Isolation, screening and characterization of the potential microbes to enhance the conversion of food-wastes to bio-fertilizer. In: AIP Conference Proceedings: 2019. AIP Publishing LLC: 020048

Joshi, A., Dabhi, M., & Kashyap, R. (2015). Extraction of enzymes from potato peels substrate using bacillus subtilis. International Journal of Current Microbiology and Applied Sciences, 4(8), 451–458.

Pleissner, D., & Lin, C. S. K. (2013). Valorisation of food waste in biotechnological processes. Sustainable Chemical Processes, 1, 1–6.

Abd-Elhalem, B. T., El-Sawy, M., Gamal, R. F., & Abou-Taleb, K. A. (2015). Production of amylases from Bacillus amyloliquefaciens under submerged fermentation using some agro-industrial by-products. Annals of Agricultural Sciences, 60(2), 193–202.

Meenakshi, G. (2015). Nutritional evaluation and utilization of pea pod powder for preparation of jaggery biscuits. Journal of Food Processing and Technology. https://doi.org/10.4172/2157-7110.1000522

Sadh, P. K., Kumar, S., Chawla, P., & Duhan, J. S. (2018). Fermentation: A boon for production of bioactive compounds by processing of food industries wastes (by-products). Molecules, 23(10), 2560.

Adelodun, A. A., Hassan, U. O., & Nwachuckwu, V. O. (2020). Environmental, mechanical, and biochemical benefits of water hyacinth (Eichhornia crassipes). Environmental Science and Pollution Research, 27(24), 30210–30221.

Ahmed, H. R., Badawi, H., Ali, S., & Fayez, M. (2018). The floating aquatic water hyacinth (Eichhornia crassipes) is a multi-uses macrophyte for fuel ethanol production and pathogen control. Int J Eng Sci, 8(12), 19406–19418.

Zucconi, L., Canini, F., Temporiti, M. E., & Tosi, S. (2020). Extracellular enzymes and bioactive compounds from Antarctic terrestrial fungi for bioprospecting. International Journal of Environmental Research and Public Health, 17(18), 6459.

Singh, A., Bajar, S., Devi, A., & Pant, D. (2021). An overview on the recent developments in fungal cellulase production and their industrial applications. Bioresource Technology Reports, 14, 100652.

Fatani, S., Saito, Y., Alarawi, M., Gojobori, T., & Mineta, K. (2021). Genome sequencing and identification of cellulase genes in Bacillus paralicheniformis strains from the Red Sea. BMC Microbiology, 21, 1–12.

Bouchareb, E. M., Derbal, K., Bedri, R., Menas, S., Bouchareb, R., & Dizge, N. (2022). Enhanced fermentative hydrogen production from potato waste by enzymatic pretreatment. Environmental Technology. https://doi.org/10.1080/09593330.2022.2154171

Deshmukh, M., & Pande, A. (2022). Comparative study for production of biofuel from potato peel waste as feedstock by different enzymes. Enzyme Engineering, 11, 175.

Ude, M. U., Oluka, I., & Eze, P. C. (2020). Optimization and kinetics of glucose production via enzymatic hydrolysis of mixed peels. Journal of Bioresources and Bioproducts, 5(4), 283–290.

Acknowledgments

All the authors acknowledge their parent institutes. The authors extend their appreciation to the Researchers supporting Project number (RSP2023R56), King Saud University, Riyadh, Saudi Arabia. Author N.S. thankfully acknowledges, DST for WOS-B project (DST/WOS-B/ER-3/2021(G) and Department of Chemical Engineering &Technology, IIT (BHU) Varanasi.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Authors of the manuscript declare that there are no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Srivastava, N., Khan, P.A., Lal, B. et al. Production Enhancement of Bacterial Cellulase Cocktail Using Potato Peels Waste Feedstock and Combination of Water Hyacinth Root and Pea Pod Extract as Natural Nutrient Media: Application in Bioconversion of Potato Peels. Mol Biotechnol (2023). https://doi.org/10.1007/s12033-023-00789-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12033-023-00789-w