Abstract

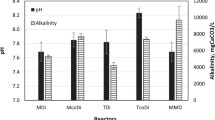

Batch experiments were performed to evaluate the biohydrogen and biomethane production by co-digestion of chicken manure and food waste in a two-stage mesophilic fermentation process. Results showed that no hydrogen was produced in the first stage of sole chicken manure fermentation, while methane yield was 247.3 mL·g−1-VS. By comparison, the co-digestion process with food waste proportions of 50–85% obtained hydrogen yields of 15.5–57.5 mL·g−1-VS, and the methane yields and maximum specific methane production rates were also improved by 7.0–16.7% and 80%, respectively. Moreover, the highest hydrogen and methane yields were achieved during sole food waste fermentation process. The acetate was the main volatile fatty acid (VFA) produced during sole chicken manure fermentation process in the first stage. Statistical analysis revealed that hydrogen production from co-digestion process and sole food waste fermentation process followed the n-butyrate-type pathway. Meanwhile, it should be noticed that the co-fermentation of chicken manure and food waste had antagonistic effects on the hydrogen fermentation, implying that there might be some inhibition factors existing in chicken manure or produced during the co-fermentation process. At the beginning of methane fermentation, the VFA profiles were similar to those at the end of hydrogen fermentation, and the main VFA compositions changed to acetate and propionate in the latter period of methane production. The volatile solid removal efficiencies were also promoted in co-digestion process compared with sole chicken manure digestion, which were increased by 9.7–14.4% with food waste proportions of 50–80%.

Graphical abstract

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code Availability

Not applicable.

References

NBSC (National Bureau of Statistics of China) (2020) China Statistical Yearbook [M], China Staistics Press, Beijing. Section 12.14. https://data.stats.gov.cn/easyquery.htm?cn=C01. Accessed 31 September 2021.

Fuchs, W., Wang, X., Gabauer, W., et al. (2018). Tackling ammonia inhibition for efficient biogas production from chicken manure: Status and technical trends in Europe and China[J]. Renewable and Sustainable Energy Reviews, 97, 186–199. https://doi.org/10.1016/j.rser.2018.08.038

Franqueto, R., Silva, J. D. D., Starick, E. K., et al. (2020). Anaerobic codigestion of bovine manure and banana tree leaf: The effect of temperature variability on biogas yield in different proportions of waste[J]. Journal of Material Cycles and Waste, 22(Part 2, 1), 1444–1458. https://doi.org/10.1007/s10163-020-01033-2

Massé, D. I., Croteau, F., & Masse, L. (2007). The fate of crop nutrients during digestion of swine manure in psychrophilic anaerobic sequencing batch reactors[J]. Bioresource Technology, 98(15), 2819–2823. https://doi.org/10.1016/j.biortech.2006.07.040

Pan, J., Ma, J., Zhai, L., et al. (2019). Enhanced methane production and syntrophic connection between microorganisms during semi-continuous anaerobic digestion of chicken manure by adding biochar[J]. Journal of Cleaner Production, 240, 118178. https://doi.org/10.1016/j.jclepro.2019.118178

Wang, M., Sun, X., Li, P., et al. (2014). A novel alternate feeding mode for semi-continuous anaerobic co-digestion of food waste with chicken manure[J]. Bioresource Technology, 164, 309–314. https://doi.org/10.1016/j.biortech.2014.04.077

Sun, C., Cao, W., Banks, C. J., et al. (2016). Biogas production from undiluted chicken manure and maize silage: A study of ammonia inhibition in high solids anaerobic digestion[J]. Bioresource Technology, 218, 1215–1223. https://doi.org/10.1016/j.biortech.2016.07.082

Liu, X. Y., Li, R. Y., Ji, M., et al. (2013). Hydrogen and methane production by co-digestion of waste activated sludge and food waste in the two-stage fermentation process: Substrate conversion and energy yield[J]. Bioresource Technology, 146, 317–323. https://doi.org/10.1016/j.biortech.2013.07.096

Oladejo, O. S., Dahunsi, S. O., Adesulu-Dahunsi, A. T., et al. (2020). Energy generation from anaerobic co-digestion of food waste, cow dung and piggery dung[J]. Bioresource Technology, 313, 123694. https://doi.org/10.1016/j.biortech.2020.123694

Tuan Yusof, T. R., Abdul Rahman, N. A., Ariff, A., et al. (2019). Evaluation of hydrogen and methane production from co-digestion of chicken manure and food waste[J]. Polish Journal of Environmental Studies, 28(4), 3003–3014. https://doi.org/10.15244/pjoes/86222

Liu, X., Li, R., & Ji, M. (2019). Effects of two-stage operation on stability and efficiency in co-digestion of food waste and waste activated sludge[J]. Energies, 12(14), 2748. https://doi.org/10.3390/en12142748

Guo, X. M., Trably, E., Latrille, E., et al. (2010). Hydrogen production from agricultural waste by dark fermentation: A review[J]. International Journal of Hydrogen Energy, 35(19), 10660–10673. https://doi.org/10.1016/j.ijhydene.2010.03.008

IRENA (The International Renewable Energy Agency) (2019) Hydrogen-A renewable energy perspective. The 2nd Hydrogen Energy Ministerial Meeting. https://www.irena.org/publications/2019/Sep/Hydrogen-Arenewable-energy-perspective. Accessed 31 September 2021.

Jarunglumlert, T., Prommuak, C., Putmai, N., et al. (2018). Scaling-up bio-hydrogen production from food waste: Feasibilities and challenges[J]. International Journal of Hydrogen Energy, 43(2), 634–648. https://doi.org/10.1016/j.ijhydene.2017.10.013

Kobayashi, T., Xu, K.-Q., Li, Y.-Y., et al. (2012). Evaluation of hydrogen and methane production from municipal solid wastes with different compositions of fat, protein, cellulosic materials and the other carbohydrates[J]. International Journal of Hydrogen Energy, 37(20), 15711–15718. https://doi.org/10.1016/j.ijhydene.2012.05.044

Aslan, M., Gümüş, M., & Türkmenler, H. (2020). The effect of organic loading, protein and carbohydrate on biohydrogen production from soft shell of red pistachio, sugar beet pulp, and olive pulp cake[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 1-13. https://doi.org/10.1080/15567036.2020.1829197

APHA (Ed.). (2005). Standard methods for the examination of water and wastewater (21st ed.). APHA.

Yu, Q., Cui, S., Sun, C., et al. (2021). Synergistic effects of anaerobic co-digestion of pretreated corn stover with chicken manure and its kinetics[J]. Applied Biochemistry and Biotechnology, 193(2), 515–532. https://doi.org/10.1007/s12010-020-03445-0

Rafieenia, R., Pivato, A., Campanaro, S., et al. (2019). Study of microbial dynamics during optimization of hydrogen production from food waste by using LCFA-rich agent[J]. Bioresource Technology Reports, 5, 157–163. https://doi.org/10.1016/j.biteb.2019.01.011

Kim, S. H., Han, S. K., & Shin, H. S. (2004). Feasibility of biohydrogen production by anaerobic co-digestion of food waste and sewage sludge[J]. International Journal of Hydrogen Energy, 29(15), 1607–1616. https://doi.org/10.1016/j.ijhydene.2004.02.018

Niu, Q., Qiao, W., Qiang, H., et al. (2013). Mesophilic methane fermentation of chicken manure at a wide range of ammonia concentration: Stability, inhibition and recovery[J]. Bioresource Technology, 137(Complete), 358–367. https://doi.org/10.1016/j.biortech.2013.03.080

Dalkilic, K., & Ugurlu, A. (2017). Influence of hydraulic retention time and reactor configuration during fermentation of diluted chicken manure[J]. Applied Biochemistry and Biotechnology, 181(1), 157–176. https://doi.org/10.1007/s12010-016-2205-6

Jurgutis, L., Slepetiene, A., Volungevicius, J., et al. (2020). Biogas production from chicken manure at different organic loading rates in a mesophilic full scale anaerobic digestion plant[J]. Biomass and Bioenergy, 141, 105693. https://doi.org/10.1016/j.biombioe.2020.105693

Dalkilic, K., & Ugurlu, A. (2015). Biogas production from chicken manure at different organic loading rates in a mesophilic-thermopilic two stage anaerobic system[J]. Journal of Bioscience and Bioengineering, 120(3), 315–322. https://doi.org/10.1016/j.jbiosc.2015.01.021

Algapani, D. E., Qiao, W., Ricci, M., et al. (2019). Bio-hydrogen and bio-methane production from food waste in a two-stage anaerobic digestion process with digestate recirculation[J]. Renewable Energy, 130, 1108–1115. https://doi.org/10.1016/j.renene.2018.08.079

Cheng, J., Ding, L., Lin, R., et al. (2016). Fermentative biohydrogen and biomethane co-production from mixture of food waste and sewage sludge: Effects of physiochemical properties and mix ratios on fermentation performance[J]. Applied Energy, 184, 1–8. https://doi.org/10.1016/j.apenergy.2016.10.003

Ghimire, A., Sposito, F., Frunzo, L., et al. (2016). Effects of operational parameters on dark fermentative hydrogen production from biodegradable complex waste biomass[J]. Waste Management, 50(Apr.), 55–64. https://doi.org/10.1016/j.wasman.2016.01.044

Gao, C., Zhao, M., Huang, Z., et al. (2018). Hydrogen consumption capacity assessment and its inhibition in the dry anaerobic digestion process from food waste[J]. Journal of Renewable and Sustainable Energy, 10(5), 053104. https://doi.org/10.1063/1.5045117

Ziara, R. M. M., Miller, D. N., Subbiah, J., et al. (2019). Lactate wastewater dark fermentation: The effect of temperature and initial pH on biohydrogen production and microbial community[J]. International Journal of Hydrogen Energy, 44(2), 661–673. https://doi.org/10.1016/j.ijhydene.2018.11.045

Guo, R., Liu, X., Hu, Y., et al. (2020). Stronger stimulation of waste activated sludge anaerobic fermentation by a particular amount of micron-sized zero valent iron[J]. Applied Biochemistry and Biotechnology, 192(1), 313–324. https://doi.org/10.1007/s12010-020-03339-1

Wang, Y., & Wang, S. (2021). Soft sensor for VFA concentration in anaerobic digestion process for treating kitchen waste based on SSAE-KELM[J]. IEEE Access, 9, 36466–36474. https://doi.org/10.1109/ACCESS.2021.3063231

Kaur, G., Johnravindar, D., & Wong, J. W. C. (2020). Enhanced volatile fatty acid degradation and methane production efficiency by biochar addition in food waste-sludge co-digestion: A step towards increased organic loading efficiency in co-digestion[J]. Bioresource Technology, 308, 123250. https://doi.org/10.1016/j.biortech.2020.123250

Liu, X., Li, R., Ji, M., et al. (2020). Effects of initial pH on two-stage biogas production and hydrolysis in a co-digestion process of food waste and waste activated sludge[J]. Environmental Engineering Science, 38(4), 266–276. https://doi.org/10.1089/ees.2020.0221

Wang, Y., Zhang, Y., Wang, J., et al. (2009). Effects of volatile fatty acid concentrations on methane yield and methanogenic bacteria[J]. Biomass and Bioenergy, 33(5), 848–853. https://doi.org/10.1016/j.biombioe.2009.01.007

Bojti, T., Kovacs, K. L., Kakuk, B., et al. (2017). Pretreatment of poultry manure for efficient biogas production as monosubstrate or co-fermentation with maize silage and corn stover[J]. Anaerobe, 46, 138–145. https://doi.org/10.1016/j.anaerobe.2017.03.017

Chen, Y., Xiao, N., Zhao, Y., et al. (2012). Enhancement of hydrogen production during waste activated sludge anaerobic fermentation by carbohydrate substrate addition and pH control[J]. Bioresource Technology, 114(none), 349–356. https://doi.org/10.1016/j.biortech.2012.03.052

Saad, M. F. M., Rahman, N. A. A., & Yusoff, M. Z. M. (2019). Hydrogen and methane production from co-digestion of food waste and chicken manure[J]. Polish Journal of Environmental Studies, 28(4), 2805–2814. https://doi.org/10.15244/pjoes/83670

Acknowledgements

The authors are grateful to the financial support from the National Key R&D Program of China (2018YFD1100503).

Funding

This work was supported by the National Key R&D Program of China (2018YFD1100503).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Formal analysis and investigation: Xinyuan Liu and Yuyu Yang. Writing—original draft preparation: Xinyuan Liu. Writing—review and editing: Nan Wu. Funding acquisition: Hui Zhao. Supervision: Yong Wei and Huiyong Shan. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Co-digestion of food waste (FW) and chicken manure (CM) produced H2 and CH4.

• The lowest H2 and CH4 yields were obtained at CM proportions of 0–30%.

• Antagonistic effects on H2 fermentation occurred in co-fermentation of FW and CM.

• H2 production from FW and co-substrates followed n-butyrate pathway.

• Digestion efficiencies were enhanced by co-digestion compared to sole CM digestion.

Supplementary Information

ESM 1

(DOC 72 kb)

Rights and permissions

About this article

Cite this article

Liu, X., Yang, Y., Wu, N. et al. Co-production of Biohydrogen and Biomethane from Chicken Manure and Food Waste in a Two-Stage Anaerobic Fermentation Process. Appl Biochem Biotechnol 194, 3706–3720 (2022). https://doi.org/10.1007/s12010-022-03945-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-022-03945-1