Abstract

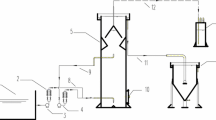

The anaerobic treatment of raw vinasse in a combined system consisting in two methanogenic reactors, up-flow anaerobic sludge blanket (UASB) + anaerobic packed bed reactors (APBR), was evaluated. The organic loading rate (OLR) was varied, and the best condition for the combined system was 12.5 kg COD m−3day−1 with averages of 0.289 m3 CH4 kg COD r−1for the UASB reactor and 4.4 kg COD m−3day−1 with 0.207 m3 CH4 kg COD r−1 for APBR. The OLR played a major role in the emission of H2S conducting to relatively stable quality of biogas emitted from the APBR, with H2S concentrations <10 mg L−1. The importance of the sulphate to COD ratio was demonstrated as a result of the low biogas quality recorded at the lowest ratio. It was possible to develop a proper anaerobic digestion of raw vinasse through the combined system with COD removal efficiency of 86.7% and higher CH4 and a lower H2S content in biogas.

Similar content being viewed by others

Abbreviations

- AD:

-

Anaerobic digestion

- OLR:

-

Organic loading rate

- COD:

-

Chemical oxygen demand, g L−1

- SRB:

-

Sulphate-reducing bacteria

- LDPF:

-

Low-density polyurethane foam

- ɳCOD:

-

COD removal efficiency

- TS:

-

Total solids, g L−1

- TVS:

-

Total volatile solids, g L−1

- VSS:

-

Volatile suspended solids, g L−1

- TKN:

-

Total nitrogen, g L−1

- VFA:

-

Volatile fatty acids, g L−1

- TIC:

-

Total inorganic carbonate, g L−1

- Q:

-

Volumetric flow

- HAc:

-

Acetic acid, g L−1

- HPr:

-

Propionic acid, g L−1

- HBu:

-

Butyric acid, g L−1

- HVa:

-

Valeric acid, g L−1

- UASB:

-

Up-flow anaerobic sludge blanket

- APBR:

-

Anaerobic packed bed reactors

- DHS:

-

Down-flow hanging sponge

- SR:

-

Sulphate reducing tank

- ASTBR:

-

Anaerobic structured-bed reactor

- AR:

-

Acidification reactor

- SAnMBR:

-

Submerged anaerobic membrane bioreactor

- AFBR:

-

Anaerobic fluidized bed reactor

- GBABR:

-

Granular bed anaerobic baffled reactor

- CSTR:

-

Continuously stirred tank reactor

- UASFB:

-

Hybrid up-flow anaerobic sludge-filter bed reactor

- AH:

-

Anaerobic hybrid reactor

- USSB:

-

Modified sludge blanket reactor

- SBR:

-

Sequential batch reactor

- MS-UASB:

-

Multistaged up-flow anaerobic sludge blanket

References

Moraes, B. S., Zaiat, M., & Bonomi, A. (2015). Anaerobic digestion of vinasse from sugar cane ethanol production in Brazil: challenges and perspectives. Renewable and Sustainable Energy Reviews, 44, 888–903.

Christofoletti, C. A., Escher, J. P., Correia, J. E., Urbano, M. J. F., & Fontanetti, C. S. (2013). Sugarcane vinasse: environmental implications of its use. Review. Waste Management, 33, 2752–2761.

Fuess, L. T., & Garcia, M. (2014). Review. Implications of stillage land disposal: a critical review on the impacts of fertigation. Journal of Environmental Management, 145, 210–229.

España, E., Mijangos, J., Barahona, L., Domíguez, J., Hernández, G., & Alzate, L. (2011). Review: vinasse: characterization and treatments. Waste Management & Research, 29, 1235–1250.

Moraes, B. S., Junqueira, T. L., Pavanello, L. G., Cavalett, O., Mantelatto, P. E., Bonomi, A., & Zaiat, M. (2014). Anaerobic digestion of vinasse from sugarcane biorefineries in Brazil from energy, environmental, and economic perspectives: profit or expense? Applied Energy, 113, 825–835.

Wilkie, A., Riedesel, K., & Owens, J. (2000). Stillage characterization and anaerobic treatment of ethanol stillage from conventional and cellulosic feedstocks. Biomass and Bioenergy, 19, 63–102.

Pant, D., & Adholeya, A. (2007). Biological approaches for treatment of distillery wastewater: a review. Bioresource Technology, 98, 2321–2334.

Janke, L., Leite, A. F., Batista, K., Silva, W., Nikolausz, M., Nelles, M., & Stinner, W. (2016). Enhancing biogas production from vinasse in sugarcane biorefineries: effects of urea and trace elements supplementation on process performance and stability. Bioresource Technology. doi:10.1016/j.biortech.2016.01.110.

Vlyssides, A., Barampouti, E. M., Mai, S., Stamatoglou, A., & Tsimas, E. (2010). Alternative biological systems for the treatment of vinasse from wine. Wat. Sci. Tech., 62(12), 2899–2904.

España-Gamboa, E., Mijangos-Cortés, J. O., Hernández-Zárate, G., Domínguez Maldonado, J. A., & y Alzate-Gaviria, L. M. (2012). Methane production by treating vinasses from hydrous ethanol using a modified UASB reactor. Biotechnology for Biofuels, 5, 82.

Mota, V. T., Santos, F. S., & Amaral, M. C. S. (2013). Two-stage anaerobic membrane bioreactor for the treatment of sugarcane vinasse: assessment on biological activity and filtration performance. Bioresource Technology., 146, 494–503.

Siqueira, L. M., Damiano, E. S. G., & Silva, E. L. (2013). Influence of organic loading rate on the anaerobic treatment of sugarcane vinasse and biogás production in fluidized bed reactor. Journal of Environmental Science and Health, Part A: Toxic/Hazardous Substances and Environmental Engineering, 48(13), 1707–1716.

Thanikal, J. V., Torrijos, M., Habouzit, F., & Moletta, R. (2007). Treatment of distillery vinasse in a high rate anaerobic reactor using low density polyethylene supports. Wat.Sci. Tech., 56(2), 17–24.

Acharya, B. K., Mohana, S., & Madamwar, D. (2008). Anaerobic treatment of distillery spent wash—a study on upflow anaerobic fixed film bioreactor. Bioresource Technology, 99(11), 4621–4626.

Balloch, M. I., Akunna, J. C., & Collier, P. J. (2007). The performance of a phase separated granular bioreactor treating brewery wastewater. Bioresource Technology, 98(9), 1849–1855.

Méndez-Acosta, H. O., Snell-Castro, R., Alcaraz-González, V., González-Alvarez, V., & Pelayo-Ortiz, C. (2010). Anaerobic treatment of tequila vinasses in a CSTR-type digester. Biodegradation, 21(3), 357–363.

Rajagopal, R., Mehrotrai, M., Kumar, P., & Torrijos, M. (2010). Evaluation of a hybrid upflow anaerobic sludge-filter bed reactor: effect of the proportion of packing medium on performance. Wat. Sci. Tech., 61(6), 1441–1450.

Nasr, N., Elbeshbishy, E., Hafez, H., Nakhla, G., Hesham, M., & Naggar, E. (2012). Comparative assessment of single-stage and two-stage anaerobic digestion for the treatment of thin stillage. Bioresource Technology, 111, 122–126.

Onodera, T., Sase, S., Choeisai, P., Yoochatchaval, W., Sumino, H., Yamaguchi, T., Ebie, Y., Xu, K., Tomioka, N., Mizuochi, M., & Syutsubo, K. (2013). Development of a treatment system for molasses wastewater: the effects of cation inhibition on the anaerobic degradation process. Bioresource Technology, 131, 295–302.

Wolmarans, B., de Villiers, H., & G. (2002). Start-up of a UASB effluent treatment plant on distillery wastewater. Water SA, 28(1), 63–68.

Kaparaju, P., Serrano, M., & Angelidaki, I. (2010). Optimization of biogas production from wheat straw stillage in UASB reactor. Applied Energy, 87, 3779–3783.

Asif, M. L., Ghufran, R., Abdul, Z. W., & Ahmad, A. (2011). Integrated application of upflow anaerobic sludge blanket reactor for the treatment of wastewaters. Water Research, 45, 4683–4699.

Rivera, A., González, J. S., Castro, R., Guerrero, B., & Nieves, G. (2002). Tratamiento de efluentes de destilería en un filtro anaerobio de flujo ascendente. Revista Internacional de Contaminación Ambiental, 18(3), 131–137.

Yu, H. Q., Zhao, Q. B., & Tang, Y. (2006). Anaerobic treatment of winery wastewater using laboratory-scale multi- and single-fed filters at ambient temperatures. Process Biochemistry, 41, 2477–2481.

Cabrera-Díaz, A., Dueñas-Moreno, J., Véliz-Lorenzo, E., Díaz-Marrero, M. A., Menéndez-Gutiérrez, C. L., Oliva-Merencio, D., Pereda-Reyes, I., & Zaiat, M. (2016). Combined treatment of vinasse by an upflow anaerobic filter-reactor and ozonation process. Brazilian Journal of Chemical Engineering, 33(4), 753–762.

Singh, S. P., & Prerna, P. (2009). Review of recent advances in anaerobic packed-bed biogas reactors. Renewable and Sustainable Energy Reviews, 13, 1569–1575.

Cresson, R., Carrére, H., Delgénes, J. P., & Bernet, N. (2006). Biofilm formation during the start-up period of an anaerobic biofilm reactor—impact of nutrient complementation. Biochemical Engineering Journal., 30, 55–62.

Sunil, K. G., Gupta, S. K., & Singh, G. (2007). Biodegradation of distillery spent wash in anaerobic hybrid reactor. Water Research, 41, 721–730.

Buitrón, G., Kumar, G., Martinez-Arce, A., & Moreno, G. (2014). Hydrogen and methane production via a two-stage processes (H2-SBR + CH4-UASB) using tequila vinasses. International Journal of Hydrogen Energy, 39, 19249–19255.

Choeisai, P., Jitkam, N., Silapanoraset, K., Yubolsai, C., Yoochatchaval, W., Yamaguchi, T., Onodera, T., & Syutsubo, K. (2014). Sugarcane molasses-based bio-ethanol wastewater treatment by two-phase multi-staged up-flow anaerobic sludge blanket (UASB) combination with up-flow UASB and down-flow hanging sponge. Wat. Sci. Tech., 69(6), 1174–1180.

Fuess, L. T., Kiyuna, L. S. M., Ferraz Jr., A. D. N., Persinoti, G. F., Squina, F. M., Garcia, M. L., & Zaiat, M. (2017). Thermophilic two-phase anaerobic digestion using an innovative fixed-bed reactor for enhanced organic matter removal and bioenergy recovery from sugarcane vinasse. Applied Energy, 189, 480–491.

Fdz-Polanco, F., Fdz-Polanco, M., Fernandez, N., Urueña, M. A., García, P. A., & Villaverde, S. (2001). New process for simultaneous removal of nitrogen and sulphur under anaerobic conditions. Water Research, 35, 1111–1114.

Khanal, S. K. (2008). In S. K. Khanal (Ed.), Bioenergy recovery from sulfate-rich waste streams and strategies for sulfide removal: anaerobic biotechnology for bioenergy production: principles and applications. Singapore: Wiley.

Barrera, E. L., Spanjers, H., Romero, O., Rosa, E., & Dewulf, J. (2014). Characterization of the sulfate reduction process in the anaerobic digestion of a very high strength sulfate rich vinasse. Chemical Engineering Journal, 248, 383–393.

Escudié, R., Cresson, R., Delgenès, J.-P., & Bernet, N. (2011). Review. Control of start-up and operation of anaerobic biofilm reactors: an overview of 15 years of research. Water Research, 45, 1–10.

APHA, AWWA, WEF. (2005). Standards methods for the examination of water and wastewater (21st ed.). Washington DC: American Public Health Association/American Water Works Association/Water Environmental Federation.

Dubois, S. M., Gilles, K. A., Hamilton, J. L., Rebers, P. A., & Smith, F. (1956). Colorimetric methods for determination of sugar and related substance. Analytical Chemistry, 228, 13–21.

Lossie, U., and Pütz, P. (2008). Targeted control of biogas plants with the help of FOS/TAC. Practice report. Germany.

Adorno, T. M. A., Hirasawa, S. J., & Varesche, A. M. B. (2014). Development and validation of two methods to quantify volatile acids (C2-C6) by GC/FID: headspace (automatic and manual) and liquid-liquid extraction (LLE). American Journal of Analytical Chemistry, 5, 406–414.

Michaud, S., Bernet, N., Buffière, P., & Delgenès, J. P. (2005). Use of the methane yield to indicate the metabolic behavior of methanogenic biofilms. Process Biochemistry, 40, 2751–2755.

Gao, M., She, Z., & Jin, C. (2007). Performance evaluation of a mesophilic (37°C) upflow anaerobic sludge blanket reactor in treating distiller’s grains wastewater. Journal of Hazardous Materials, 141, 808–813.

Michaud, S., Bernet, N., Buffière, P., Roustan, M., & Moletta, R. (2002). Technical note. Methane yield as a monitoring parameter for the start-up of anaerobic fixed film reactors. Water Research, 36, 1385–1391.

Akarsubasi, A. T., Ince, O., Oz, N. A., Kırda, R. B., & Ince, B. K. (2006). Evaluation of performance, acetoclastic methanogenic activity and archaeal composition of full-scale UASB reactors treating alcohol distillery wastewaters. Process Biochemistry, 41, 28–35.

Silva, A. J., Hirasawa, J. S., Varesche, M. B., Foresti, E., & Zaiat, M. (2006). Evaluation of support materials for the immobilization of sulfate-reducing bacteria and methanogenic archaea. Anaerobe, Ecology/environmental microbiology, 12, 93–98.

Pérez-García, M., Romero-García, L. I., Rodríguez-Cano, R., & Sales-Márquez, D. (2005a). High rate anaerobic thermophilic technologies for distillery wastewater treatment. Wat.Sci. Tech., 51(1), 191–198.

Pérez-García, M., Romero-García, L. I., Rodríguez-Cano, R., & Sales-Márquez, D. (2005b). Effect of the pH influent conditions in fixed film rectors for anaerobic thermophilic treatment of wine-distillery wastewater. Wat.Sci. Tech., 51(1), 183–189.

Wang, Y., Zhang, Y., Wang, J., & Meng, L. (2009). Effects of volatile fatty acid concentrations on methane yield and methanogenic bacteria. Biomass and Bioenergy, 33, 848–853.

López, G. L. M., Pereda, R. I., Dewulf, J., Budde, J., Heiermann, M., & Vervaeren, H. (2014). Effect of liquid hot water pre-treatment on sugarcane press mud methane yield. Bioresource Technology, 169, 284–290.

Pagés-Díaz, J., Westman, J., Taherzadeh, M. J., Pereda-Reyes, I., & Sárvári, I. H. (2015). Semi-continuous co-digestion of solid cattle slaughterhouse waste with other waste streams: interactions within the mixtures and methanogenic community structure. Chemical Engineering Journal, 273, 28–36.

Pereda-Reyes, I., Pagés-Díaz, J., Sárvári, I. H. (2015). Anaerobic biodegradation of solid substrates from agro-industrial activities: slaughterhouse wastes and agro-wastes. In Biodegradation and bioremediation of polluted system: new advances and technologies. Ed: InTech. Croatia.

Acknowledgements

This research was supported by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (Capes), Brazil, Project CAPES/MES-Cuba 117/11.

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

• The anaerobic process performance in the treatment of raw vinasse in a combined system of two methanogenic reactors (UASB + APBR) was evaluated under different OLR.

• The sulphate to COD ratio was demonstrated to be of major relevance in the biogas quality.

• The combination of the two anaerobic methanogenic reactors clearly improved the process performance, as a result not only of a higher COD removal efficiency but also of a higher CH4 and a lower H2S content in comparison with the UASB operating as a stand-alone unit.

Rights and permissions

About this article

Cite this article

Cabrera-Díaz, A., Pereda-Reyes, I., Oliva-Merencio, D. et al. Anaerobic Digestion of Sugarcane Vinasse Through a Methanogenic UASB Reactor Followed by a Packed Bed Reactor. Appl Biochem Biotechnol 183, 1127–1145 (2017). https://doi.org/10.1007/s12010-017-2488-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-017-2488-2