Abstract

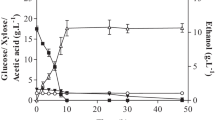

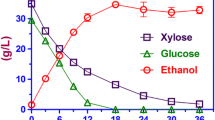

In the field of biofuel ethanol, high-concentration- reducing sugars made from cellulosic materials lay the foundation for high-concentration ethanol fermentation. In this study, corn stover was pre-treated in a process combining chemical methods and steam explosion; the cellulosic hydrolyzed sugars obtained by fed-batch saccharification were then used as the carbon source for high-concentration ethanol fermentation. Saccharomyces cerevisiae 1308, Angel yeast, and Issatchenkia orientalis were shake-cultured with Pachysolen tannophilus P-01 for fermentation. Results implied that the ethanol yields from the three types of mixed strains were 4.85 g/100 mL, 4.57 g/100 mL, and 5.02 g/100 mL (separately) at yield rates of 91.6, 89.3, and 92.2 %, respectively. Therefore, it was inferred that shock-fermentation using mixed strains achieved a higher ethanol yield at a greater rate in a shorter fermentation period. This study provided a theoretical basis and technical guidance for the fermentation of industrial high-concentrated cellulosic ethanol.

Similar content being viewed by others

References

Gray, K. A., Zhao, L. S., & Emptage, M. (2006). Bioethanol. Current Opinion in Chemical Biology, 10, 141–146.

Farrell, A. E., Plevin, R. J., Turner, B. T., Jones, A. D., O’Hare, M., & Kammen, D. M. (2006). Ethanol can contribute to energy and environmental goals. Science, 311, 506–508.

Yang, H. L., Lu, Y., Feng, Z. M., & Wang, L. (2012). Research progress Journal of biofuel on environmental impact. Natural Resources, 27, 344–352.

Demirbas, M. F. (2009). Biorefineries for biofuel upgrading: a critical review. Applied Energy, 86, S151–S161.

Sims, R. E. H., Mabee, W., Saddler, J. N., & Taylor, M. (2010). An overview of second generation biofuel technologies. Bioresource Technology, 101, 1570–1580.

Hendriks, A. T. W. M., & Zeeman, G. (2009). Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresorce Technology, 100, 10–18.

Yang, M. H., Li, W. L., Liu, B. B., Li, Q., & Xing, J. M. (2010). High-concentration sugars production from corn stover based on combined pretreatments and fed-batch process. Bioresource Technology, 101, 4884–4888.

Casey, G. P., Magnus, C. A., & Ingledew, W. M. (1983). High gravity brewing: nutrient enhanced production of high concentrations of ethanol by brewing yeast. Biotechnology Letter, 5, 429–434.

Song, X. Y., Ouyang, J., Li, X., Yun, C. Q., Yong, Q., & Yu, S. Y. (2008). High concentration fermentation of pentose to ethanol. Chinese Journal of Bioprocess Engineering, 6, 19–24.

Chang, C., Wang, D., Wang, L. F., & Ma, X. J. (2012). Comparative study on processes of simultaneous saccharification and fermentation with high solid concentration for cellulosic ethanol production. Journal of Chemical Industry and Engineering, 63, 935–940.

Xu, H. X., & Duan, G. (2010). Effect of temperature on the no cook, very high gravity ethanol fermentation process. Chinese Journal of Biotechnology, 26, 330–334.

Soest, P. J. V., Robertson, J. B., & Lewis, B. A. (1991). Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. Journal of Dairy Science, 74, 3583–3597.

Wang, F. Q., Liu, Y. Q., Zhang, R., Wang, Y. Y., Xie, H., & Song, A. D. (2014). Effect of byproducts in lignocellulose hydrolysates on ethanol fermentation by Issatchenkia orientalis. Chinese Journal of Biotechnology, 30, 753–764.

Song, A. D., Wang, M. D., Ren, T. B., Xie, H., & Zhang, S. M. (2006). Study on the straw saccharification conditions with cellulase and xylanase simultaneously. Journal of Xinyang Normal University, 19, 181–184.

Song, A. D., Ren, T. B., Xie, H., Pei, G. Q., & Zhang, B. L. (2006). Effect of chemical pretreatment on enzymatic saccharification of maize straw. Chemical Bioengineering, 23, 31–33.

Ren, T. B., Zhang, L. L., Song, A. D., Xie, H., Wang, F. Q., & Zhang, B. L. (2010). Research on multi-enzyme hydrolysis of rice straw. Renewable Energy, 28, 67–72.

Tran, A. V., & Chanber, R. P. (1985). Red oak wood derived inhibitors in the ethanol fermentation of xylose by Pichiastipitis CBS 5776. Biotechnology Letter, 7, 841–846.

Zhang, H. R., Qin, X. X., & Silvio, S. S. (2009). Novel isolates for biological detoxification of lignocellulosic hydrolyate. Applied Biochemical and Biotechnology, 152, 199–212.

Acknowledgments

This research was financially supported by National High Technology Research and Development Program (863 Program) in Biology and Medicine Technology Field of China (No. 2012AA022301B) and the Science and Technology Cooperation Project between Henan Province and Academy of China (No. 102106000018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, H., Wang, F., Yin, S. et al. The Preparation and Ethanol Fermentation of High-Concentration Sugars from Steam-Explosion Corn Stover. Appl Biochem Biotechnol 176, 613–624 (2015). https://doi.org/10.1007/s12010-015-1599-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-015-1599-x