Abstract

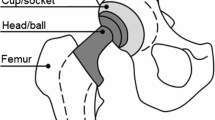

The study is aimed to develop a hip joint wear simulator using a modular design approach to help experimentally monitor and control critical wear parameters to validate in-silico wear models. The proper control and application of wear parameters such as the range of motion, and the applied force values while estimating the lost material due to wear are essential for thorough analysis of wear phenomena for artificial joints. The simulator's dynamics were first modeled, then dynamic loading data was used to calculate the forces, which were further used for topology optimization to reduce the forces acting on each joint. The reduction of the link weights, connected to the actuators, intends to improve the quality of motion transferred to the femoral head. The modular design approach enables topology-optimized geometry, associated gravitational and dynamic forces, resulting in a cost-effective, energy-efficient product. Moreover, this design allows integration of the subject specific data by allowing different boundary conditions following the requirements of industry 5.0. Overall, the in-vitro motion stimulations of the hip-joint prosthesis and the modular design approach used in the study might help improve the accuracy and the effectiveness of wear simulations, which could lead into the development of better and longer-lasting joint prostheses for all. The subject-specific and society-based daily life data implemented as boundary conditions enable inclusion of the personalized effects. Next, with the results of the simulator, CEN Workshop Agreement (CWA) application is intended to cover the personalized effects for previously excluded populations, providing solution to inclusive design for all.

Similar content being viewed by others

References

Carlet, G.: Essai expérimental sur la locomotion humaine : étude de la marche [Experimental test on human locomotion: Study of walking]. Impr. E. Martinet, Paris (1872)

Marey, É.J.: De la locomotion terrestre chez les bipèdes et les quadrupèdes [Terrestrial locomotion in bipeds and quadrupeds]. Impr. E. Martinet, Paris (1873)

Demenÿ, G., Quénu, É.A.V.A.: Etude de la locomotion humaine dans les cas pathologiques[Study of human locomotion in pathological cases]. Station Physiologique 4, 1887–1889 (1888)

Uchida, T., Delp, S.: Biomechanics of Movement. The MIT Press, London, England (2020)

Shepherd, M.C., Gaffney, B.M.M., Song, K., Clohisy, J.C., Nepple, J.J., Harris, M.D.: Femoral version deformities alter joint reaction forces in dysplastic hips during gait. J. Biomech. 135, 111023 (2022). https://doi.org/10.1016/J.JBIOMECH.2022.111023

Bergmann, G., et al.: Hip contact forces and gait patterns from routine activities. J. Biomech. 34(7), 859–871 (2001). https://doi.org/10.1016/S0021-9290(01)00040-9

Aitken, H.D., Westermann, R.W., Bartschat, N.I., Clohisy, J.C., Willey, M.C., Goetz, J.E.: Effect of modeling femoral version and head-neck offset correction on computed contact mechanics in dysplastic hips treated with periacetabular osteotomy. J. Biomech. 141, 111207 (2022). https://doi.org/10.1016/J.JBIOMECH.2022.111207

Rydell, N.W.: Forces acting on the femoral head-prosthesis. A study on strain gauge supplied prostheses in living persons. Acta Orthop. Scand. (1966). https://doi.org/10.3109/ort.1966.37.suppl-88.01

Ingelmark, B.E., Blomgren, E.: An apparatus for the measurement of pressure, especially in human joints. Upsala Lakareforen Forh. 53(1–2), 75–94 (1948)

Mihcin, S., Ciklacandir, S., Kocak, M., Tosun, A.: Wearable motion capture system evaluation for biomechanical studies for hip joints. J. Biomech. Eng. (2021). https://doi.org/10.1115/1.4049199

Duff-barclay, B. I. and Spillman, D. T.: Total human hip joint prostheses—a laboratory study of friction and wear. vol. 181, no. 3 (1966)

Dowson, D., Walker, P.S., Longfield, M.D., Wright, V.: A joint simulating machine for load-bearing joints. Med. Biol. Eng. 8(1), 37–43 (1970). https://doi.org/10.1007/BF02551747

Walker, P.S., Gold, B.L.: The tribology (friction, lubrication and wear) of all-metal artificial hip joints. Clin. Orthop. Relat. Res. 17, 285–299 (1971). https://doi.org/10.1097/00003086-199608001-00002

Bai, S., Li, X., Angeles, J.: A review of spherical motion generation using either spherical parallel manipulators or spherical motors. Mech. Mach. Theory 140, 377–388 (2019). https://doi.org/10.1016/J.MECHMACHTHEORY.2019.06.012

Kaddick, C., Wimmer, M.A.: Hip simulator wear testing according to the newly introduced standard ISO 14242. J. Biomech. 34(SUPPL. 1), 429–442 (2001). https://doi.org/10.1016/s0021-9290(04)00168-x

Torabnia, S., Mihcin, S., and Lazoglu, I.: Parametric analysis for the design of hip joint replacement simulators. In: 2021 IEEE International Symposium on Medical Measurements and Applications (MeMeA), IEEE, Jun. 2021, pp. 1–6. doi: https://doi.org/10.1109/MeMeA52024.2021.9478689.

Tuke, M., Taylor, A., Roques, A., Maul, C.: 3D linear and volumetric wear measurement on artificial hip joints—validation of a new methodology. Precis. Eng. 34(4), 777–783 (2010). https://doi.org/10.1016/j.precisioneng.2010.06.001

Trommer, R.M., Maru, M.M.: Importance of preclinical evaluation of wear in hip implant designs using simulator machines. Revista Brasileira de Ortopedia (English Edition) 52(3), 251–259 (2017). https://doi.org/10.1016/j.rboe.2016.07.004

Zanini, F., Carmignato, S., Savio, E., Affatato, S.: Uncertainty determination for X-ray computed tomography wear assessment of polyethylene hip joint prostheses. Precis. Eng. 52, 477–483 (2018). https://doi.org/10.1016/j.precisioneng.2018.02.009

Partridge, S., Tipper, J.L., Al-Hajjar, M., Isaac, G.H., Fisher, J., Williams, S.: Evaluation of a new methodology to simulate damage and wear of polyethylene hip replacements subjected to edge loading in hip simulator testing. J. Biomed. Mater. Res. B Appl. Biomater. 106(4), 1456–1462 (2018). https://doi.org/10.1002/jbm.b.33951

Viitala, R., Saikko, V.: Effect of random variation of input and various daily activities on wear in a hip joint simulator. J. Biomech. 106, 1–7 (2020). https://doi.org/10.1016/j.jbiomech.2020.109831

Safartoobi, M., Dardel, M., Daniali, H.M.: Gait cycles of passive walking biped robot model with flexible legs. Mech. Mach. Theory 159, 104292 (2021). https://doi.org/10.1016/J.MECHMACHTHEORY.2021.104292

Lunn, D.E., Chapman, G.J., Redmond, A.C.: Hip kinematics and kinetics in total hip replacement patients stratified by age and functional capacity. J. Biomech. 87, 19–27 (2019). https://doi.org/10.1016/j.jbiomech.2019.02.002

Sriramdas, R., Cruz, R., Garcia, A.J., Sharpes, N.L., Priya, S.: Human gait energy harvesting through decoupled suspended load backpacks. Mech. Mach. Theory 171, 1047 (2022). https://doi.org/10.1016/J.MECHMACHTHEORY.2022.104734

Srivastava, G., Christian, N., Fred Higgs, C.: A predictive framework of the tribological impact of physical activities on metal-on-plastic hip implants. Biotribology (2021). https://doi.org/10.1016/j.biotri.2020.100156

Watson, B., Radcliffe, D., and Dale, P.: A meta-methodology for the application of DFX design guidelines. In: Design for X, Dordrecht: Springer Netherlands, pp. 441–462 (1996)

Formentini, G., Bouissiere, F., Cuiller, C., Dereux, P.-E., Favi, C.: Conceptual design for assembly methodology formalization: systems installation analysis and manufacturing information integration in the design and development of aircraft architectures. J. Ind. Inf. Integr. 26, 100327 (2022). https://doi.org/10.1016/j.jii.2022.100327

George, A., Ali, M., Papakostas, N.: Utilising robotic process automation technologies for streamlining the additive manufacturing design workflow. CIRP Ann. 70(1), 119–122 (2021). https://doi.org/10.1016/j.cirp.2021.04.017

Huang, G.Q., Lee, S.W., Mak, K.L.: Web-based product and process data modelling in concurrent ‘design for X.’ Robot. Comput. Integr. Manuf. 15(1), 53–63 (1999). https://doi.org/10.1016/S0736-5845(98)00028-3

Mcharek, M., Hammadi, M., Azib, T., Larouci, C., Choley, J.-Y.: Collaborative design process and product knowledge methodology for mechatronic systems. Comput. Ind. 105, 213–228 (2019). https://doi.org/10.1016/j.compind.2018.12.008

Buzuku, S., Kraslawski, A.: Use of design structure matrix for analysis of critical barriers in implementing eco-design initiatives in the pulp and paper Industry. Proc. Manuf. 11, 742–750 (2017). https://doi.org/10.1016/j.promfg.2017.07.175

van Beek, T.J., Erden, M.S., Tomiyama, T.: Modular design of mechatronic systems with function modeling. Mechatronics 20(8), 850–863 (2010). https://doi.org/10.1016/j.mechatronics.2010.02.002

Ungethüm, M., Hildebrandt, J., Jäger, M., Moslé, H.G.: Ein neuer Simulator zur Testung von Totalendoprothesen für das Hüftgelenk. Arch. Orthop. Unfallchir. 77(4), 304–314 (1973). https://doi.org/10.1007/BF00418916

Shan, X., Cheng, G.: Structural error and friction compensation control of a 2(3PUS + S) parallel manipulator. Mech. Mach. Theory 124, 92–103 (2018). https://doi.org/10.1016/J.MECHMACHTHEORY.2018.02.004

Haider, H., Weisenburger, J.N., Garvin, K.L.: Simultaneous measurement of friction and wear in hip simulators. Proc. Inst. Mech. Eng. H 230(5), 373–388 (2016). https://doi.org/10.1177/0954411916644476

Sonntag, R., et al.: Friction in hip bearings under continuous normal walking conditions: influence of swing phase load and patient weight. Biotribology (2021). https://doi.org/10.1016/j.biotri.2021.100182

Ali, M., Al-Hajjar, M., Partridge, S., Williams, S., Fisher, J., Jennings, L.M.: Influence of hip joint simulator design and mechanics on the wear and creep of metal-on-polyethylene bearings. Proc Inst Mech Eng H 230(5), 389–397 (2016). https://doi.org/10.1177/0954411915620454

ISO/TC 150/SC 4 Bone and joint replacements comittee, ISO 14242–1:2014 Implants for surgery—wear of total hip-joint prostheses—Part 1 Loading and displacement parameters for wear-testing machines and corresponding environmental conditions for test,” 2014.

Zhang, J., Wei, J., Mao, Y., Li, H., Xie, Y., Zhu, Z.: Range of hip joint motion in developmental dysplasia of the hip patients following total hip arthroplasty with the surgical technique using the concept of combined anteversion: a study of Crowe I and II patients. J. Arthroplasty 30(12), 2248–2255 (2015). https://doi.org/10.1016/j.arth.2015.06.056

Stephens, J.D., Hurst, J.M., Morris, M.J., Berend, K.R., Lombardi, A.V., Crawford, D.A.: Correlation between patient-reported ‘happiness’ with knee range of motion and objective measurements in primary knee arthroplasty. J. Arthroplasty (2022). https://doi.org/10.1016/j.arth.2022.01.037

Usuelli, F.G., Indino, C., Leardini, A., Manzi, L., Ortolani, M., Caravaggi, P.: Range of motion of foot joints following total ankle replacement and subtalar fusion. Foot Ankle Surg. 27(2), 150–155 (2021). https://doi.org/10.1016/j.fas.2020.03.015

Dong, H., Dong, B., Zhang, C., Wang, D.: An equivalent mechanism model for kinematic accuracy analysis of harmonic drive. Mech. Mach. Theory 173, 104825 (2022). https://doi.org/10.1016/J.MECHMACHTHEORY.2022.104825

Kim, K., Kim, J., Kim, J., Kim, H.S., Kim, J.: Multidisciplinary methodology to predict the performance of modular actuator-based manipulator. Robot. Comput. Integr. Manuf. 52, 46–64 (2018). https://doi.org/10.1016/j.rcim.2018.02.007

Manka, M., Uhl, T.: Mechatronic design of fault detection isolation and restoration systems for rotating machineries. Mech. Mach. Theory 44(7), 1436–1449 (2009). https://doi.org/10.1016/j.mechmachtheory.2008.11.011

Lynch, K.M., Park, F.C.: Modern Robotics Mechanics, Planning, and Control, 1st edn. Cambridge University Press, Cambridge (2017)

Dai, J.S.: Euler–Rodrigues formula variations, quaternion conjugation and intrinsic connections. Mech. Mach. Theory 92, 144–152 (2015). https://doi.org/10.1016/J.MECHMACHTHEORY.2015.03.004

Bendsøe, M.P., Sigmund, O.: Topology Optimization. Springer, Berlin (2004)

Carabin, G., Wehrle, E., Vidoni, R.: A review on energy-saving optimization methods for robotic and automatic systems. Robotics (2017). https://doi.org/10.3390/robotics6040039

Bauccio, M.: ASM Metals Reference Book. ASM International, Materials Park, OH (1993)

Acknowledgements

The authors thank the Manufacturing and Automation Research Center of Koc University for providing facilities for conducting the research jointly with the Mechanical Engineering Department of Izmir Institute of Technology.

Funding

This research was funded by the TUBITAK 2232 International Outstanding Researchers Funding Scheme with Grant No of 118C188' New Generation Implants for All' project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical Approval and Consent to Participate

Not applicable.

Consent for Publication

All authors give consent to the publication of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Torabnia, S., Mihcin, S. & Lazoglu, I. Design and manufacturing of a hip joint motion simulator with a novel modular design approach. Int J Interact Des Manuf 18, 401–417 (2024). https://doi.org/10.1007/s12008-023-01506-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-023-01506-2