Abstract

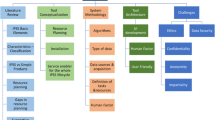

Internet of Things (IoT) and Cloud Computing are receiving a lot of attention lately because they can offer a new technique for smart sensing and connectivity from man-to-man, man-to-machine, and machine-to-machine, as well as on-demand usage and effective sharing of resources, alternately. For the Industrial IoT to function as an infrastructure for data collection of shop floor equipment, cloud computing is required; distributed computing would move to the edge due to speed requirements for real-time processing of massive data. The method describes the standard manufacturing system built on a private cloud system that gathers data in real time from smart technologies linked to shop-floor objects.The study aims to design a general structure for information and data acquisition, processing, and collection at the edges of massive production controllers, where the approach is determined by the collection of shop-floor objects. The implementation of a multi-criteria adaptive scheduling technique that conducts accurate and effective scheduling or rescheduling of production processes in real time while taking shop-floor data and condition-based services into consideration. To move towards the Internet of Things, the different parts of the created cyber-physical mechanism will be applied in a cloud setting. The entities are made up of industrial assets that embed work-in-progress on items throughout their production phase of Cyber-Physical Production Systems (CPPS), which work together intelligently in such systems to achieve and maintain the manufacturing process's optimum, manage disruptions, and adapt to changing circumstances.The CPPS architecture joins a system with the IoT nodes made up of IoT accesses, and instruments, including PC-style terminals holding the resource agents with such a private cloud service. The decentralized MES network of a semi-hierarchical cloud-based CPPS controlling system is comprised of both networks. The development of the manufacturing process, controlling, monitoring, including optimization, as well as the archiving of historical data, are the major functions of the management system. The assessment of power consumed is presented together with an implementation framework. The entire method is easy to apply in different kinds of businesses and yielded incredibly satisfying results.

Similar content being viewed by others

References

.Kang, H. S., et al. Smart manufacturing: past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Green Technol. 3 (1), 111–128 (2016) https://doi.org/10.1007/s40684-016-0015-5

Mourtzis, D., Vlachou, E.: A cloud-based cyber-physical system for adaptive shop-floor scheduling and condition-based maintenance. J. Manuf. Syst. 47, 179–198 (2018)

Aheleroff, S., et al.: IoT-enabled smart appliances under industry 4.0: a case study. Adv. Eng. Inform. 43, 101043 (2020)

Kuo, T.-C., Hsu, N.-Y., Li, T.Y., Chao, C.-J.: Industry 4.0 enabling manufacturing competitiveness: delivery performance improvement based on theory of constraints. J. Manuf. Syst. 60, 152–161 (2021)

Morariu, C., Morariu, O., Răileanu, S., Borangiu, T.: Machine learning for predictive scheduling and resource allocation in large scale manufacturing systems. Comput. Ind. 120, 103244 (2020)

Ding, K., Chan, F.T., Zhang, X., Zhou, G., Zhang, F.: Defining a digital twin-based cyber-physical production system for autonomous manufacturing in smart shop floors. Int. J. Prod. Res. 57(20), 6315–6334 (2019)

Lu, Y., Xu, X.: Cloud-based manufacturing equipment and big data analytics to enable on-demand manufacturing services. Robot. Comput.-Integr. Manuf. 57, 92–102 (2019). https://doi.org/10.1016/j.rcim.2018.11.006

Liu, C., Jiang, P., Jiang, W.: Web-based digital twin modeling and remote control of cyber-physical production systems. Robot. Comput.Integr. Manuf. 64, 101956 (2020). https://doi.org/10.1016/j.rcim.2020.101956

Răileanu, S., Anton, F., Borangiu, T., Anton, S., Nicolae, M.: A cloud-based manufacturing control system with data integration from multiple autonomous agents. Comput. Ind. 102, 50–61 (2018). https://doi.org/10.1016/j.compind.2018.08.004

Lu, Y., Xu, X.: Cloud-based manufacturing equipment and big data analytics to enable on-demand manufacturing services. Robot. Comput. Integr. Manuf. 57, 92–102 (2018). https://doi.org/10.1016/j.rcim.2018.11.006

Zhang, Z., Wang, X., Zhu, X., Cao, Q., Tao, F.: Cloud manufacturing paradigm with ubiquitous robotic system for product customization. Robot. Comput.-Integr. Manuf. 60, 12–22 (2019). https://doi.org/10.1016/j.rcim.2019.05.015

Damjanovic-Behrendt, V., Behrendt, W.: An open source approach to the design and implementation of digital twins for Smart Manufacturing. Int. J. Comput. Integr. Manuf. 32(4–5), 366–384 (2019). https://doi.org/10.1080/0951192X.2019.1599436

Laghari, A. A., Wu, K., Laghari, R. A., Ali M., and Khan, A. A. A review and state of art of internet of things (IoT). Arch. Comput. Methods Eng., 1–19, (2021).

Lăzăroiu, G., Kliestik, T., Novak, A.: Internet of Things smart devices, industrial artificial intelligence, and real-time sensor networks in sustainable cyber-physical production systems. J. Self-Gov. Manag. Econ. 9(1), 20–30 (2021)

Kampa, T., Müller C. K., and Großmann D., IP-based architecture for an edge cloud enabled factory: concept and requirements. In 2022 IEEE 18th International Conference on Factory Communication Systems (WFCS), (2022), 1–8.

Borangiu, T., Trentesaux, D., Thomas, A., Leitão, P., Barata, J.: Digital transformation of manufacturing through cloud services and resource virtualization. Comput. Ind. 108, 150–162 (2019)

Răileanu, S., Anton, F., Borangiu, T., Anton, S., Nicolae, M.: A cloud-based manufacturing control system with data integration from multiple autonomous agents. Comput. Ind. 102, 50–61 (2018)

Raileanu, S., Borangiu, T., Morariu, O., and Iacob, I., (2018) Edge computing in industrial IoT framework for cloud-based manufacturing control. In 2018 22nd International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, 261–266, (2018) https://doi.org/10.1109/ICSTCC.2018.8540725.

Arrais, R., Costa, C.M., Ribeiro, P., Rocha, L.F., Silva, M., Veiga, G.: On the development of a collaborative robotic system for industrial coating cells. Int. J. Adv. Manuf. Technol. 115(3), 853–871 (2021)

Gadaleta, M., Pellicciari, M., Berselli, G.: Optimization of the energy consumption of industrial robots for automatic code generation. Robot. Comput.Integr. Manuf. 57, 452–464 (2019)

Nieto, E.A.B., Rezazadeh, S., Gregg, R.D.: Minimizing energy consumption and peak power of series elastic actuators: a convex optimization framework for elastic element design. IEEEASME Trans. Mechatron. 24(3), 1334–1345 (2019)

Anton, F., Borangiu, T., Morariu, O., Răileanu, S., Anton, S and Ivănescu, N., Decentralizing cloud robot services through edge computing. In International Conference on Robotics in Alpe-Adria Danube Region. 618–626, (2018)

Lins, T., Oliveira, R.A.R.: Cyber-physical production systems retrofitting in context of industry 4.0. Comput. Ind. Eng. (2020). https://doi.org/10.1016/j.cie.2019.106193

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khan, S.I., Kaur, C., Al Ansari, M.S. et al. Implementation of cloud based IoT technology in manufacturing industry for smart control of manufacturing process. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01366-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01366-w