Abstract

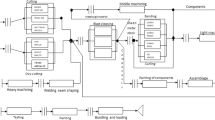

This current effort proposes implementing virtual manufacturing in a shop for the automotive industry, specifically for the assembly of VLO (Vehicle Layout) operation, axle drop, engine drop, exhaust system drop/ATS system, and cab drop. The primary objective is to synchronize the material handling system’s frequency (Takt Time) with that of the Electric powered Monorail Hoist System. Different production rates can be achieved by adjusting the combination of process parameters and keeping the process flow among the material handling machinery uninterrupted. An assembly line for chassis was simulated by using varying volume levels. The effectiveness of the system was evaluated with simulated data. Delmia Quest software facilitates in finding problems in process planning by using 3D simulation in place of time-consuming manual processes. The utilization of 3D simulation during process flow design helps to verify equipment motion and spot crashing and smuggling on the assembly line. The manufacturing process was modelled in CATIA® for design, and then simulated in real time using Delmia QUEST for simulation. The proposed effort seeks to improve understanding of production on assembly lines and the many manufacturing methods and steps required during the manufacturing process in order to reduce costs of production and idling while simultaneously increasing productivity. Operator loading accelerated by 5% because of the added 14.18 min of job content, and the target number of vehicles per shift has been achieved.

Similar content being viewed by others

References

Mor, R., Bhardwaj, A., Singh, S., Sachdeva, A.: Productivity gains through standardization-of-work in a manufacturing company. J. Manuf. Technol. Manag. 30, 899–919 (2019)

Cuatrecasas, L., Fortuny-Santos, J., Vintro, C.: The operations-time chart: a graphical tool to evaluate the performance of production systems—from batch-and-queue to lean manufacturing. Comput. Ind. Eng. 61, 663–675 (2011)

Hareable, S., Ptimal, O., Epetitive, R., Cheduling, S., Odel, M.: 8, 270–280 (2001)

Volpato, G.: New perspectives on automation. in In: Automation in Automotive Industries, pp. 11–30. Springer Berlin Heidelberg, Berlin, Heidelberg (1999)

Colim, A., Faria, C., Braga, A.C., Sousa, N., Rocha, L., Carneiro, P., Costa, N., Arezes, P.: Towards an ergonomic assessment framework for industrial assembly workstations—A case study. Appl. Sci. 10, 3048 (2020)

Boysen, N., Fliedner, M., Scholl, A.: Assembly line balancing: Which model to use when? Int. J. Prod. Econ. 111, 509–528 (2008)

Voell, C., Chatterjee, P., Rauch, A.: Product Lifecycle Management to Support Industry 4.0. Springer International Publishing, Cham (2018)

Seppälä, P., Klemola, S.: How do employees perceive their organization and job when companies adopt principles of lean production? Hum. Factors Ergon. Manuf. 14, 157–180 (2004)

Salleh, N.A.M., Kasolang, S., Mustakim, M.A., Kuzaiman, N.A.: The study on optimization of streamlined process flow based on delmia quest simulation in an automotive production system. Procedia Computer Science 105, 191–196 (2017)

Roberts, S.D., Villa, C.D.: On a multiproduct assembly line balancing problem. AIIE Trans. 2, 361–364 (1970)

Sims, T., da Wan, H.H.: -D.H. Constraint identification techniques for lean manufacturing systems. Robot Comput. Integr. Manuf. 43, 50–58 (2017)

Botti, L., Mora, C., Regattieri, A.: Integrating ergonomics and lean manufacturing principles in a hybrid assembly line. Comput. Ind. Eng. 111, 481–491 (2017)

Yuan, M., Yu, H., Huang, J., Ji, A.: Reconfigurable assembly line balancing for cloud manufacturing. J. Intell. Manuf. 30(6), 2391–2405 (2019)

Dimitriadis, S.G.: Assembly line balancing and group working: a heuristic procedure for workers’ groups operating on the same product and workstation. Comput. Oper. Res. 33(9), 2757–2774 (2006)

Yang, S.L., Xu, Z.G., Wang, J.Y.: Modelling and production configuration optimization for an assembly shop. Int. J. Simul. Model. 18(2), 366–377 (2019)

Roth, N., Deuse, J., Biedermann, H.: A framework for System Excellence assessment of production systems, based on lean thinking, business excellence, and factory physics. Int. J. Prod. Res. 58, 1074–1091 (2020)

Eryuruk, S.H., Kaloglu, F., Baskak, M.: Assembly line balancing in a clothing company. Fibres Text. East. Eur. 16, 93–98 (2008)

Shah, M.N., Dixit, S., Kumar, R., Jain, R., Anand, K.: Causes of delays in slum reconstruction projects in India. Int. J. Constr. Manag. 21(5), 452–467 (2021). https://doi.org/10.1080/15623599.2018.1560546

Dixit, S., Stefańska, A., Musiuk, A.: Architectural form finding in arboreal supporting structure optimisation. Ain Shams Eng. J. 12(2), 2321–2329 (2021). https://doi.org/10.1016/j.asej.2020.08.022

Dixit, S., Stefańska, A., Musiuk, A., Singh, P.: Study of enabling factors affecting the adoption of ICT in the indian built environment sector. Ain Shams Eng. J. 12(2), 2313–2319 (2021). https://doi.org/10.1016/j.asej.2020.09.020

Dixit, S., Stefańska, A., Singh, P.: Manufacturing technology in terms of digital fabrication of contemporary biomimetic structures. Int. J. Constr. Manage. (2021). https://doi.org/10.1080/15623599.2021.2015105

Mishra, L., Dixit, S., Nangia, R., Saurabh, K., Kumar, K., Sharma, K.: A brief review on segregation of solid wastes in indian region. Mater. Today Proc. 69, 419–424 (2022). https://doi.org/10.1016/j.matpr.2022.09.070

Dixit, S., et al.: Replacing E-waste with coarse aggregate in architectural engineering and construction industry. Mater. Today Proc. 2353–2358 (2022). https://doi.org/10.1016/j.matpr.2021.12.154

Arora, R., et al.: Potential utilization of waste materials for the production of green concrete: a review. Mater. Today Proc. 69, 317–322 (2022). https://doi.org/10.1016/j.matpr.2022.08.542

Arora, R., Kumar, K., Dixit, S., Mishra, L.: Analyze the outcome of waste material as cement replacement agent in basic concrete. Mater. Today Proc. 56, 1877–1881 (2022). https://doi.org/10.1016/j.matpr.2021.11.148

Kumar, K., et al.: Comparative analysis of waste materials for their potential utilization in green concrete applications. Materials 15(12), 4180 (2022)

Dixit, S., Singh, P.: Investigating the disposal of E-waste as in architectural engineering and construction industry. Mater. Today Proc. 56, 1891–1895 (2022). https://doi.org/10.1016/j.matpr.2021.11.163

Rane, A.B., Sunnapwar, V.K., Chari, N.R., Sharma, M.R., Jorapur, V.S.: Improving performance of lock assembly line using lean and simulation approach. Int. J. Bus. Perform. Manag. 18(1), 101–124 (2017)

Bukchin, J., Darel, E., Rubinovitz, J.: Team-oriented assembly systems design: a new approach. Int. J. Prod. Econ. 51, 47–57 (1997)

Pastor, R., Andres, C., Duran, A., Perez, M.: Tabu search algorithms for an industrial multi-product and multi-objective assembly line balancing problem with reduction of the task dispersion. J. Oper. Res. Soc. 53, 1317–1323 (2002)

Zhou, W., Li, S.Q., Huang, Y.Q., Wang, J.F.: Simulation based capacity optimization of a general assembly line with extremely unbalanced station process time. In: IEEE International Conference on Industrial Engineering and Engineering Management, pp. 1245–1249. (2019)

Shellshear, E., Berlin, R., Carlson, J.S.: Maximizing smart factory systems by incrementally updating point clouds. IEEE Comput. Graph. Appl. 35(2), 62–69 (2015)

Cannas, V.G., Pero, M., Pozzi, R., Rossi, T.: Complexity reduction and kaizen events to balance manual assembly lines: an application in the field. Int. J. Prod. Res. 56, 3914–3931 (2018)

Lu, H., Liu, X., Pang, W., Ye, W.H., Wei, B.S.: Modeling and simulation of aircraft assembly line based on Quest. Adv. Mater. Res. 569, 666–669 (2012)

Qu, S., Jiang, Z.: Amemetic algorithm approach for batch-model assembly line balancing problem of sub-block in shipbuilding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 228, 1290–1304 (2014)

Tao, R., Ren, H., Peng, X.: Modeling, Design and Simulation of Systems, vol. 751. Springer Singapore, Singapore (2017)

Coleman, J.B., Vaghefi, R.A., Heijunka: A key to the Toyota production system. Prod. Invent. Manag. J. 35, 31–35 (1994)

Kumar, P., Prasad, S.B., Patel, D., Gupta, L., Nag, M.B., Chadha, P.: Production improvement on the assembly line through cycle time optimization. Int. J. Interact. Des. Manuf. (IJIDeM). (2022). https://doi.org/10.1007/s12008-022-01031-8

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, P., Prasad, S.B., Patel, D. et al. Optimization of cycle time assembly line for mass manufacturing. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01343-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01343-3