Abstract

Continuous growth of the manufacturing sector is resulting in to higher energy demand due to which the manufacturing costs and greenhouse gas emissions are also increasing. Beside reduction in energy consumption; improvement in energy efficiency, power factor and reduction in cutting temperatures are also vital to ensure better sustainability of the machining sector. This work evaluates the trade-offs between energy, heat generation and cutting quality during milling of medium carbon steel (EN8) alloy steel. The effects of input process parameters viz. spindle speed, feed rate, axial depth of cut, radial depth of cut and tool helix angle has been studied on the energy consumption, energy efficiency, power factor, cutting temperatures, surface roughness response parameters. The inclusion of helix angle as an input factor and, using energy efficiency and power factor as output parameters are the major highlights of this work. The machining experiments were conducted using response surface methodology for design of experiments. The multi objective optimization was carried out by using desirability approach, for three different groups of response variables considering the different importance of energy consumption, cutting temperatures and surface roughness, under different manufacturing circumstances. The predictability of the multiple regression approach was found to be more than 90% for all the responses which highlights model significance. The direct and interaction effect were studied and discussed in details for all the responses. The values of the composite desirability achieved in all the three types of optimization problems were on higher side (0.813, 1 and 0.794). The results of the optimization were confirmed by conducting the experiments the optimized settings. The percentage error between experimental and RSM predicted result was found to be within acceptable limits. This study can be helpful for reducing the energy consumption and cutting temperature without compromising on surface roughness, in the machining of medium carbon steel.

Similar content being viewed by others

Abbreviations

- ANOVA:

-

Analysis of variance

- CE:

-

Cutting energy

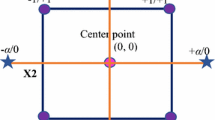

- CCD:

-

Central composite design

- CCRD:

-

Central composite rotatable design

- DoE:

-

Design of experiment

- EE:

-

Energy efficiency

- F:

-

Feed rate

- GA:

-

Genetic algorithm

- H:

-

Helix angle

- MRR:

-

Material removal rate

- N:

-

Spindle speed

- NSGA-II:

-

Non-dominated sorting genetic algorithm-II

- PF:

-

Power factor

- PCM:

-

Power consumed for actual cutting of material (in Watt)

- PCA:

-

Power consumed by the machine during air cutting (no workpiece)

- PC:

-

Power consumed for cutting

- Ra:

-

Surface roughness

- SEC:

-

Specific energy consumption

- SA:

-

Simulated annealing

- TECM:

-

Total energy consumption during machining

- T:

-

Workpiece surface temperature rise

- Y:

-

Radial depth of cut

- Z:

-

Axial depth of cut

References

Moradnazhad, M., Unver, H.O.: Energy efficiency of machining operations: a review Energy efficiency of machining operations: a review. Proc. IMechE Part B J. Eng. Manuf. 231, 1871–1889 (2016). https://doi.org/10.1177/0954405415619345

Hayajneh, M.T., Tahat, M.S., Bluhm, J.: A study of the effects of machining parameters on the surface roughness in the end-milling process. Jordan J. Mech. Indust. Eng. 1(1), 1–5 (2007)

Newman, S.T., Nassehi, A., Dhokia, V.: Energy efficient process planning for CNC machining. CIRP J. Manuf. Sci. Technol. 5(2), 127–136 (2012). https://doi.org/10.1016/j.cirpj.2012.03.007

Bilga, P.S., Singh, S., Kumar, R.: Optimization of energy consumption response parameters for turning operation using Taguchi method. J. Clean. Prod. 137, 1406–1417 (2016). https://doi.org/10.1016/j.jclepro.2016.07.220

Kuram, E., Ozcelik, B., Bayramoglu, M., Demirbas, E., Tolga, B.: Optimization of cutting fluids and cutting parameters during end milling by using D-optimal design of experiments. J. Clean. Prod. 42, 159–166 (2013). https://doi.org/10.1016/j.jclepro.2012.11.003

Campatelli, G., Lorenzini, L., Scippa, A.: Optimization of process parameters using a Response Surface Method for minimizing power consumption in the milling of carbon steel. J. Clean. Prod. 66, 309–316 (2014). https://doi.org/10.1016/j.jclepro.2013.10.025

Yan, J., Li, L.: Multi-objective optimization of milling parameters – the trade-offs between energy, production rate and cutting quality. J. Clean. Prod. 52, 462–471 (2013). https://doi.org/10.1016/j.jclepro.2013.02.030

Zhang, C., Li, W., Jiang, P., Gu, P.: Experimental investigation and multi-objective optimization approach for low-carbon milling operation of aluminum. Proc. IMechE Part C J. Mech. Eng. Sci. (2016). https://doi.org/10.1177/0954406216640574

Öztürk, B., Kara, F.: Calculation and estimation of surface roughness and energy consumption in milling of 6061 alloy. Adv. Mater. Sci. Eng. 2020, 1–12 (2020). https://doi.org/10.1155/2020/5687951

Kadirgama, K., Abou-El-Hossein, K.A.: Power prediction model for milling 618 stainless steel using response surface methodology. Am. J. Appl. Sci. 2(7), 1182–1187 (2005)

Kadirgama, K., Abou-El-Hossein, K.A.: Torque, power and cutting force prediction model by using response surface method and factorial design. Edit. Adv. Board e 18(1), 20–44 (2005)

Bağcı, E., Aykut, Ş: The effects of tool position, coating and cutting parameters on forces, power, MRR and wear in face milling of stellite 6. Arabian J. Sci. Eng. 39(11), 8135–8146 (2014). https://doi.org/10.1007/s13369-014-1354-6

Ahmed, S.U., Arora, R.: Quality characteristics optimization in CNC end milling of A36 K02600 using Taguchi’s approach coupled with artificial neural network and genetic algorithm. Int. J. Syst. Assur. Eng. Manag. 10(4), 676–695 (2019). https://doi.org/10.1007/s13198-019-00796-8

Noor, R.M., Ramli, M.I., Zubair, A.F., Hemdi, A.R., Kataraki, P.: Optimization of cutting parameters to improve power consumption and material removal rate in high efficiency milling. J. Mines Metals Fuels 69(12A), 163 (2022). https://doi.org/10.18311/jmmf/2021/30149

Sahu, N.K., Andhare, A.B.: Modelling and multiobjective optimization for productivity improvement in high speed milling of Ti–6Al–4V using RSM and GA. J. Brazil. Soc. Mech. Sci. Eng. 39(12), 5069–5085 (2017). https://doi.org/10.1007/s40430-017-0804-y

Malghan, R.L., Rao, K.M.C., Shettigar, A.K., Rao, S.S., D’Souza, R.J.: Application of particle swarm optimization and response surface methodology for machining parameters optimization of aluminium matrix composites in milling operation. J. Brazil. Soc. Mech. Sci. Eng. 39(9), 3541–3553 (2016). https://doi.org/10.1007/s40430-016-0675-7

Helu, M., Rühl, J., Dornfeld, D., Werner, P., Lanza, G.: Evaluating trade-offs between sustainability, performance, and cost of green machining technologies. In 18th CIRP International Conference on Life Cycle Engineering, pp. 195–200. (2011). https://doi.org/10.1007/978-3-642-19692-8.

Bhushan, R.K.: Optimization of cutting parameters for minimizing power consumption and maximizing tool life during machining of Al alloy SiC particle composites. J. Clean. Prod. 39, 242–254 (2013). https://doi.org/10.1016/j.jclepro.2012.08.008

Aggarwal, A., Singh, H., Kumar, P., Singh, M.: Optimizing power consumption for CNC turned parts using response surface methodology and Taguchi’s technique—A comparative analysis. J. Mater. Process. Technol. 200(1–3), 373–384 (2008). https://doi.org/10.1016/j.jmatprotec.2007.09.041

Fata, A.: Temperature measurement during machining depending on cutting conditions. G. J. P A Sci. Tech. 1(2), 16–21 (2011)

Bacci, M., Wallbank, J.: Cutting temperature: prediction and measurement methods—a review. J. Mater. Process. Tech. 88, 195–202 (1999)

Bhirud, N.L., Gawande, R.R.: Measurement and prediction of cutting temperatures during dry milling: review and discussions. J. Brazil. Soc. Mech. Sci. Eng. 39(12), 5135–5158 (2017). https://doi.org/10.1007/s40430-017-0869-7

Tamilarasan, A., Marimuthu, K., Renugambal, A.: Investigations and optimization for hard milling process parameters using hybrid method of RSM and NSGA-II. Rev. Téc. Ing. Univ. Zulia. 39(2012), 41–54 (2016)

Tamilarasan, A., Marimuthu, K.: Multi-response optimization of hard milling process: RSM coupled with grey relational analysis. Int. J. Eng. Technol. 5(6), 4901–4913 (2014)

Tamilarasan, A., Marimuthu, K.: Multi-response optimisation of hard milling process parameters based on integrated Box-Behnken design with desirability function approach. Int. J. Mach. Mach. Mater 15(3/4), 300 (2014). https://doi.org/10.1504/IJMMM.2014.060555

M. H. F. Al Hazza, E. Y. T. Adesta, M. Y. Superianto, M. Riza, Cutting temperature and surface roughness optimization in CNC end milling using multi objective genetic algorithm. In Proceedings - 2012 International Conference on Advanced Computer Science Applications and Technologies, ACSAT 2012, pp. 275–278. (2013). https://doi.org/10.1109/ACSAT.2012.39.

Le Coz, G., Marinescu, M., Devillez, A., Dudzinski, D., Velnom, L.: Measuring temperature of rotating cutting tools: application to MQL drilling and dry milling of aerospace alloys. Appl. Thermal Eng. 36, 434–441 (2012). https://doi.org/10.1016/j.applthermaleng.2011.10.060

Li, A., Zhao, J., Pei, Z., Zhu, N.: Simulation-based solid carbide end mill design and geometry optimization. Int. J. Adv. Manuf. Technol. 71(9–12), 1889–1900 (2014). https://doi.org/10.1007/s00170-014-5638-5

Dinc, C., Lazoglu, I., Serpenguzel, A.: Analysis of thermal fields in orthogonal machining with infrared imaging. J. Mater. Technol. 198(1–3), 147–154 (2008). https://doi.org/10.1016/j.jmatprotec.2007.07.002

Vikas, V., Shyamraj, R., Varughese, A.K.: Experimental study of the influence of tool geometry by optimizing helix angle in the peripheral milling operation using Taguchi based grey relational analysis. Int. J. Adv. Eng. Manag. Sci. 2(8), 239594 (2016)

Izamshah, R., Yuhazri, M. Y., Hadzley, M., Amran, M. A.: Effects of end mill helix angle on accuracy for machining thin-rib aerospace component. vol. 315, pp. 773–777. (2013) https://doi.org/10.4028/www.scientific.net/AMM.315.773.

Sivasakthivel, P.S., Murugan, V.V., Sudhakaran, R.: Prediction of tool wear from machining parameters by response surface methodology in end milling. Int. J. Eng. Sci. Technol. 2(6), 1780–1789 (2010)

Sivasakthivel, P.S., Velmurugan, V., Sudhakaran, R.: Prediction of vibration amplitude from machining parameters by response surface methodology in end milling. Int. J. Adv. Manuf. Technol. 53, 453–461 (2011)

Sivasakthivel, P.S., Vel Murugan, V., Sudhakaran, R.: Experimental evaluation of surface roughness for end milling of Al 6063: response surface and neural network model. Int. J. Manuf. Res. 7(1), 9–25 (2012)

Sivasakthivel, P.S., Vel Murugan, V., Sudhakaran, R.: Cutting force prediction depending on process parameters by response surface methodology in milling. Int. J. Mach. Mach. Mater. 11(2), 137–153 (2012)

Hricova, J., Kovac, M., Sugar, P.: Experimental investigation of high speed milling of aluminium alloy. Tehnički Vjesnik 21(4), 773–777 (2014)

Tsao, C.C.: Grey-Taguchi method to optimize the milling parameters of aluminum alloy. Int. J. Adv. Manuf. Technol. 40(1–2), 41–48 (2009). https://doi.org/10.1007/s00170-007-1314-3

Kalidass, S., Palanisamy, P., Muthukumaran, V.: Prediction and optimisation of tool wear for end milling operation using artificial neural networks and simulated annealing algorithm. Int. J. Mach. Mach. Mater. 14(2), 142 (2013). https://doi.org/10.1504/IJMMM.2013.055734

Kalidass, S., Palanisamy, P.: Prediction of surface roughness for AISI 304 steel with solid carbide tools in end milling process using regression and ANN models. Arab. J. Sci. Eng. 39(11), 8065–8075 (2014). https://doi.org/10.1007/s13369-014-1346-6

Sivaraos, K.R., Milkey, A.R., Samsudin, A.K.: Comparison between Taguchi method and response surface. Jordan J. Mech. Ind. Eng. 8(1), 35–42 (2014)

Kilickap, E., Huseyinoglu, M., Yardimeden, A.: Optimization of drilling parameters on surface roughness in drilling of AISI 1045 using response surface methodology and genetic algorithm. Int. J. Adv. Manuf. Technol. 52(1–4), 79–88 (2011). https://doi.org/10.1007/s00170-010-2710-7

Santhanakrishnan, M., Sivasakthivel, P.S., Sudhakaran, R.: Modeling of geometrical and machining parameters on temperature rise while machining Al 6351 using response surface methodology and genetic algorithm. J. Brazil. Soc. Mech. Sci. Eng. 39(2), 487–496 (2015). https://doi.org/10.1007/s40430-015-0378-5

Patel, K., Batish, A., Bhattacharya, A.: Optimization of surface roughness in an end-milling operation using nested experimental design. Prod. Eng. 3(4–5), 361–373 (2009). https://doi.org/10.1007/s11740-009-0177-x

Sivasakthivel, P.S., Sudhakaran, R.: Optimization of machining parameters on temperature rise in end milling of Al 6063 using response surface methodology and genetic algorithm. Int. J. Adv. Manuf. Technol. 67(9–12), 2313–2323 (2013). https://doi.org/10.1007/s00170-012-4652-8

Routara, B.C., Bandyopadhyay, A., Sahoo, P.: Roughness modeling and optimization in CNC end milling using response surface method: effect of workpiece material variation. Int. J. Adv. Manuf. Technol. 40(11–12), 1166–1180 (2009). https://doi.org/10.1007/s00170-008-1440-6

Camposeco-Negrete, C.: Optimization of cutting parameters using response surface method for minimizing energy consumption and maximizing cutting quality in turning of AISI 6061 T6 aluminum. J. Clean. Prod. 91, 109–117 (2015). https://doi.org/10.1016/j.jclepro.2014.12.017

Balogun, V.A., Mativenga, P.T.: Specific energy based characterization of surface integrity in mechanical machining. Proced. Manuf. 7, 290–296 (2017). https://doi.org/10.1016/j.promfg.2016.12.072

Calvanese, M.L., Albertelli, P., Matta, A., Taisch, M., Milano, P.: Analysis of energy consumption in CNC machining centers and determination of optimal cutting conditions. (2013).

Camposeco-Negrete, C.: Optimization of cutting parameters for minimizing energy consumption in turning of AISI 6061 T6 using Taguchi methodology and ANOVA. J. Clean. Prod. 53, 195–203 (2013). https://doi.org/10.1016/j.jclepro.2013.03.049+

Yusoff, A.R., Arsyad, F.: Evaluation of surface roughness and power consumption in machining FCD 450 cast iron using coated and uncoated irregular milling tools. IOP Conf. Ser. Mater. Sci. Eng. 114, 012017 (2016). https://doi.org/10.1088/1757-899X/114/1/012017

Altıntaş, R.S., Kahya, M., Ünver, H.Ö.: Modelling and optimization of energy consumption for feature based milling. Int. J. Adv. Manuf. Technol. 86(9–12), 3345–3363 (2016). https://doi.org/10.1007/s00170-016-8441-7

Kumar, R., Bilga, P.S., Singh, S.: Multi objective optimization using different methods of assigning weights to energy consumption responses, surface roughness and material removal rate during rough turning operation. J. Clean. Prod. 164, 45–57 (2017). https://doi.org/10.1016/j.jclepro.2017.06.077

Iqbal, M., Konneh, M., Bin, M.H., Abdallah, K.A., Bin Binting, M.F.: Cutting temperature in high speed milling of silicon carbide using diamond coated tool. Int. J. Mech. Prod. Eng. 3(4), 62–66 (2015)

Kus, A., Yahya Isik, M., Cakir, S.C., Özdemir, K.: Thermocouple and infrared sensor-based measurement of temperature distribution in metal cutting. Sensors 15(1), 1274–1291 (2015). https://doi.org/10.3390/s150101274

Gosai, M., Bhavsar, S.N.: Experimental study on temperature measurement in turning operation of hardened steel (EN36). Proced. Technol. 23, 311–318 (2016). https://doi.org/10.1016/j.protcy.2016.03.032

Patel, C.H., Patel, C.P.: Parametric optimization of end milling of AISI 1018 mild steel by various lubricants with solid carbide end mills. Int. J. Eng. Res. Appl. 3, 728–732 (2013)

Patel, B., Nayak, H., Araniya, K., Champaneri, G.: Parametric optimization of temperature during CNC end milling of mild steel using RSM. Int. J. Eng. Res. Technol. 3(1), 69–73 (2014)

Bhardwaj, B., Kumar, R., Singh, P.K.: An improved surface roughness prediction model using Box-Cox transformation with RSM in end milling of EN 353. J. Mech. Sci. Technol. 28, 5149–5157 (2014). https://doi.org/10.1007/s12206-014-0837-4

Reddy, N.S.K., Rao, P.V.: A genetic algorithmic approach for optimization of surface roughness prediction model in dry milling. Mach. Sci. Technol. 9(1), 63–84 (2005). https://doi.org/10.1081/MST-200051263

Singh, C., Bhogal, S.S., Pabla, D.B., Kumar, P.: Empirical modeling of surface roughness and metal removal rate in CNC milling operation. Int. J. Innov. Technol. Res. (JITR) 2, 1120–1126 (2014)

Derringer, G., Suich, R.: Simultaneous optimization of several response variables. J. Qual. Technol. 12(4), 214–219 (1980)

Jenarthanan, M.P., Jeyapaul, R.: Optimisation of machining parameters on milling of GFRP composites by desirability function analysis using Taguchi method. Int. J. Eng. Sci. Technol. 5(4), 23–36 (2013)

Pattanaik, L.N.: Analytical Tools in Research, 1st edn. Educreation Publishing, Delhi (2017)

Kamguem, R., Djebara, A., Songmene, V.: Investigation on surface finish and metallic particle emission during machining of aluminum alloys using response surface methodology and desirability functions. Int. J. Adv. Manuf. Technol. 69(5–8), 1283–1298 (2013). https://doi.org/10.1007/s00170-013-5105-8

Montgomery, D.C.: Design and Analysis of Experiments. Willey, New York (2009)

Kivak, T.: Optimization of surface roughness and flank wear using the Taguchi method in milling of Hadfield steel with PVD and CVD coated inserts. Measurement (London) 50(1), 19–28 (2014). https://doi.org/10.1016/j.measurement.2013.12.017

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhirud, N.L., Dube, A.S., Patil, A.S. et al. Modeling and multi-objective optimization of cutting parameters using response surface method for milling of medium carbon steel (EN8). Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01267-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01267-y