Abstract

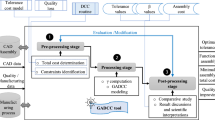

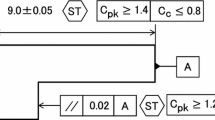

In manufacturing industry tolerance has a significant role in both the growth and the cost of the final product. Tolerance allocation is a crucial design strategy that must be used in order to achieve the dual goals of lowering the overall cost of production while keeping the appropriate degree of quality. Tolerance allocation is a vital design technique that must be implemented in order to fulfil the twin aims of reducing the total cost of production while maintaining the required level of quality. Tolerance allocation is the only method that will work for accomplishing this goal. In order to properly do tolerance charting, it is necessary to first identify the tolerance chain. It is necessary to identify each operation's working dimension and tolerance using the tolerance chain identification method. This research presents a computer-aided method for determining working dimensions and tolerance chains, as well as for computing the average sizes of working dimensions. Charts of acceptable levels of risk are utilized as the foundation for the system. The tolerances and dimensions of the blue prints, as well as the processing capacity, are input into a nonlinear optimization model so that the lowest possible manufacturing cost can be determined. In order to solve this issue, both the Genetic Algorithm (GA) and the optimization model were used.

Similar content being viewed by others

References

Goetz, S., Roth, M., Schleich, B.: Early robust design—its effect on parameter and tolerance optimization. Appl. Sci. 11, 9407 (2021)

Bouaziz, Z., Masmoudi, F.: Manufacturing simulation: computer aided tolerancing for process planning. Int. J. Simul. Model. 5, 5–15 (2006)

Thimm, G., Britton, G.A.: A matrix method for calculating working dimensions and offsets for tolerance charting. Int. J. Adv. Manuf. Technol. 20, 448–453 (2002)

Shah, J.J., Yan, Y., Zhang, B.-C.: Dimension and tolerance modeling and transformations in feature based design and manufacturing. J. Intell. Manuf. 9, 475–488 (1998)

Ji, P.: An automatic tolerance assignment approach for tolerance charting. Int J Adv Manuf Technol 9, 362–368 (1994)

Nagarajan, L., Mahalingam, S.K., Salunkhe, S., Nasr, E.A., Davim, J.P., Hussein, H.M.A.: A novel methodology for simultaneous minimization of manufacturing objectives in tolerance allocation of complex assembly. Appl. Sci. 11, 9164 (2021)

Li, W., Bai, G., Zhang, C., Wang, B.: Optimization of machining datum selection and machining tolerance allocation with genetic algorithms. Int. J. Prod. Res. 38, 1407–1424 (2000)

Ngoi, B.K.A., Fang, S.L.: Computer-aided tolerance charting. Int. J. Prod. Res. 32, 1939–1954 (1994)

Petruccioli, A., Fabio, P., Francesco, L.: Development of a Computer-Aided integrated method for the tolerance-cost multi-disciplinary optimization of an automotive engine. Int J Interact. Des. Manuf. 1–13 (2022)

Liu, Z., Lan, Y., Jia, J., Geng, Y., Dai, X., Yan, L., Hu, T., Chen, J., Matyjaszewski, K., Ye, G.: Multi-scale computer-aided design and photo-controlled macromolecular synthesis boosting uranium harvesting from seawater. Nat Commun 13, 1–12 (2022)

Armillotta, A.: Allocation of geometric tolerances in one-dimensional stackup problems. Int. J. Adv. Manuf. Technol., 122(3), 1957–1973 (2022)

Hallmann, M., Schleich, B., Wartzack, S.: From tolerance allocation to tolerance-cost optimization: a comprehensive literature review. Int J of Adv Manuf Technol 107(11–12), 4859–4912 (2020)

Polini, W.: Concurrent tolerance design. Res Eng Des 27, 23–36 (2016)

Armillotta, A., Semeraro, Q. Geometric Tolerance Specification. In:Colosimo, B.M., Senin, N., editors. Geometric Tolerances. London: Springer; 2011.

International Organization for Standardization. ISO 2768–1:1989; General tolerances - Part 1: Tolerances for linear and angular dimensions without individual tolerance indications

Speckhart, F.H.: Calculation of tolerance based on a minimum cost approach. J Eng Ind 94(2), 447–453 (1972)

Brucely, Y., Christabel Shaji, Y., Bovas Herbert Bejaxhin, A., Abeens, M.: Online acoustic emission measurement of tensile strength and wear rate for AA8011-TiC- ZrB2 hybrid composite. Surf Topogr Metrol Prop 10, 045009 (2022). https://doi.org/10.1088/2051-672X/ac9acf

Goetz, S., Schleich, B., Wartzack, S.: A new approach to first tolerance evaluations in the conceptual design stage based on tolerance graphs. Procedia CIRP 75, 167–172 (2018)

Goetz, S., Schleich, B.: Ontology-based representation of tolerancing and design knowledge for an automated tolerance specification of product concepts. Procedia CIRP 92, 194–199 (2020)

Voelcker, H.B.: The current state of affairs in dimensional tolerancing:1997. Int Manuf Sys 9(4), 205–217 (1998)

Zhao, Q., Li, T., Cao, Y., Yang, J., Jiang, X.: A rule-based exclusion method for tolerance specification of revolving components. J Eng Manuf 234(3), 527–537 (2020)

Cui, L.J., Sun, M.Y., Cao, Y.L., Zhao, Q.J., Zeng, W.H., Guo, S.R.: A novel tolerance geometric method based on machine learning. J Intel Manuf 32, 799–821 (2021)

Haghighi, P., Mohan, P., Kalish, N., Vemulapalli, P., Shah, J.J., Davidson, J.K.: Toward automatic tolerancing of mechanical assemblies: firstorder GD&T Schema Development and Tolerance Allocation. J Comp Inf Sci Eng (2015). https://doi.org/10.1115/14030939

Huang, X., Ho, T.-Y., Guo, W., Li, B., Chakrabarty, K., Schlichtmann, U.: Computer-aided design techniques for flow-based microfluidic lab-on-a-chip systems. ACM Comput. Surv. 54, 1–29 (2021)

Li, K., Gao, Y., Zheng, H., Tan, J.: A data-driven methodology to improve tolerance allocation using product usage data. J Mech Des (2021). https://doi.org/10.1115/14050400

Delos, V., Teissandier, D., Malyshev, A., Nuel, G., Garcia, S.C.: Polyhedral-based Modeling and Algorithms for Tolerancing Analysis. Comput Des 141, 103071 (2021)

Humienny, Z.: State of art in standardization in the geometrical product specification area a decade later. CIRP J. Manuf. Sci. Technol. 33, 42–51 (2021)

Petruccioli, A., Pini, F., Leali, F.: Tolerance Specification Model for Systematic Application of GD\&T in Product Design. In: ASME International Mechanical Engineering Congress and Exposition 85604, V006T06A033 (2021)

Humienny, Z.: Can ISO GPS and ASME tolerancing systems define the same functional requirements? Appl. Sci. 11, 8269 (2021)

Walter, M.S.J., Klein, C., Heling, B., Wartzack, S.: Statistical tolerance analysis—a survey on awareness, use and need in German industry. Appl. Sci. 11, 2622 (2021)

Wang, H., Yan, C., Yu, J., Wärmefjord, K.: Clamping force integrated computer aided tolerancing in composite assembly. J. Compos. Mater. 55, 1405–1417 (2021)

Martinsen, K., Assuad, C.S.A., Kito, T., Matsumoto, M., Reddy, V., Guldbrandsen-Dahl, S.: Closed loop tolerance engineering modelling and maturity assessment in a circular economy perspective. In: EcoDesign and Sustainability I, pp. 297–308. Springer, Berlin (2021)

Korbi, A., Tlija, M., Louhichi, B.: A CAD model for the tolerancing of mechanical assemblies considering non-rigid joints between parts with defects. Proc Inst Mech Eng Part B J Eng Manuf 236, 219–232 (2022)

Kenneth W, Chase.: Chapter 13—multi-dimensional tolerance analysis, chapter 14—minimum-cost tolerance allocation. Dimensioning and tolerancing handbook 453–475 (1999)

Acknowledgements

The Mechanical Engineering department at Saranathan College of Engineering in Trichy, Tamil Nadu, India, and SRM TRP Engineering College in Trichy, Tamil Nadu, India, both funded this project. We'd also like to express our gratitude to the administration, professors, and technicians who assisted us with this research.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Conceptualisation, TM, BY, PG, SN, NN, CP, SK, and KR; Data curation, TM, BY, PG, SN, NN, CP, SK, and KR; Formal analysis, TM, BY, PG, SN, NN, CP, SK and KR; Investigation, TM, BY, PG, SN, NN, CP, SK and KR; Methodology, TM, BY, PG, SN, NN, CP, SK and KR; Project administration, KR; Resources, TM, BY, PG, SN, NN, CP, SK, and KR; Software, TM, BY, PG, SN, NN, CP, SK, and KR; Supervision, KR; Validation, TM, BY, PG, SN, NN, CP, SK, and KR; Visualization, TM, BY, PG, SN, NN, CP, SK, and KR; Writing—original draft, TM, BY, PG, SN, NN, CP, SK, and KR; Data Visualization, Editing and Rewriting, TM, BY, PG, SN, NN, CP, SK, and KR.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thilak, M., Brucely, Y., Paulraj, G. et al. Computer-aided tolerance chain identification system for tolerance allocation. Int J Interact Des Manuf 17, 917–929 (2023). https://doi.org/10.1007/s12008-022-01169-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-01169-5