Abstract

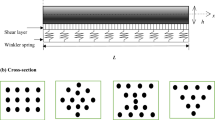

The high demand of low cost wind energy needs to design large scale HAWTB with reduced weight, which poses a great challenge to their durability. Composite materials are being employed in many wind structures such as wind energy applications. In fact, external wind loads can cause damage mechanisms and large-deflection bending leading to test the ability of long composite WT blades. The paper is a comprehensive research on structural integrity of HAWTB by testing the structural part section cutted from the blade. The 3D complex geometry part represents the critical and structural part and it supports the main local failures initiation and progressive. The present part has been used for several analysis to investigate the coupled stiffness-strength and durability performance, using ANSYS, at extreme load conditions. The most advanced results obtained from nonlinear FEA of composite structural part concern the effect of fiber material on flap-wise displacement compared to Glass fibers and kevlar49 with 42% in stiffness gain. The FE results indicates that the high critical regions are localized near the root at the bottom skin of the structure, which are driven by typical damage mechanisms. The buckling analysis confirms the compressive regions applied and revealed high local deformed in structure, which generates important rotational moment at the adhesive layers. The stress analysis of out-of-plane shear stress is presented. Besides, the results of contact evaluation between bottom skin and rib show good agreements with the predicted, consequently, the gap and frictional stress indicate serious risk of adhesive layers damage. The most local failure mode predicted is also delamination’s because extreme local out-of-plane stress is generated. In fact, the modal analysis and random vibration are conducted for the fatigue life prediction using PSD indicator. Moreover, the vibration of bottom and top skin are evaluated and good results is agreed with the anticipated. A reinforcement method has been proposed for the blade structural part by incorporate locally circular Carbon/Epoxy laminates at the failed zones and the results show important gain on strength.

Graphic Abstract

Similar content being viewed by others

Availability of data and material

Authors confirm that all relevant data and material are included in the article.

Abbreviations

- C:

-

Chord length (mm)

- \(E_{x}\) :

-

Longitudinal modulus (GPa)

- \(E_{y}\) :

-

Transversal modulus (GPa)

- \(E_{z}\) :

-

Transversal modulus (GPa)

- \(G_{xy}\) :

-

Shear modulus in x-y plane (MPa)

- \(G_{yz}\) :

-

Shear modulus in y-z plane (MPa)

- \(G_{xz}\) :

-

Shear modulus in x-z plane (MPa)

- R:

-

Shear strenght in the y-z plane (MPa)

- S:

-

Shear strenght in the x-y plane (MPa)

- \(S_{xy}\) :

-

Shear strength in x-y plane (MPa)

- \(S_{yz}\) :

-

shear strength in y-z plane (MPa)

- \(S_{xz}\) :

-

Shear strength in x-z plane (MPa)

- ACP:

-

ANSYS Composite Pre/post

- FEM:

-

Finite Element Model

- FEA:

-

Finite Element Analysis

- GFRP:

-

Glass Fiber Reinforced polymer

- CFRP:

-

Carbon Fiber Reinforced Polymer

- FRP:

-

Fiber Reinforced Polymer

- HAWT:

-

Horizontal Axis Wind Turbine

- HAWTB:

-

Horizontal Axis Wind Turbine Blade

- WT:

-

Wind Turbine

- \(\beta _{T}\) :

-

Twist angle (\(\circ \))

- \(\nu _{xy}\) :

-

xy poisson’s ratio

- \(\nu _{yz}\) :

-

yz poisson’s ratio

- \(\nu _{xz}\) :

-

xz poisson’s ratio

- \(\sigma \) :

-

Normal stress (MPa)

- \(\tau \) :

-

Shear stress (MPa)

- \(\epsilon \) :

-

Normal strain

- \(\gamma \) :

-

Distortion strain

References

Guo, S., Liu, Q., Sun, J., Jin, H.: A review on the utilization of hybrid renewable energy. Renew. Sustain. Energy Rev. 91, 1121–1147 (2018)

Maizi, M., Mohamed, M.H., Dizene, R., Mihoubi, M.C.: Noise reduction of a horizontal wind turbine using different blade shapes. Renew. Energy 117(Supplement C), 242–256 (2018)

Diaf, S., Notton, G.: Evaluation of electricity generation and energy cost of wind energy conversion systems in southern Algeria. Renew. Sustain. Energy Rev. 23, 379–390 (2013)

Hiremath, N., Young, S., Ghossein, H., Penumadu, D., Vaidya, U., Theodore, M.: Low cost textile-grade carbon-fiber epoxy composites for automotive and wind energy applications. Compos. Part B Eng., p. 108156 (2020)

Liu, H., Zhang, Z., Jia, H., Liu, Y., Leng, J.: A modified composite fatigue damage model considering stiffness evolution for wind turbine blades. Compos. Struct. 233, 111736 (2020)

Himayat, U., Baseer, U., Schmidt, S., Vadim, V.: Structural integrity analysis and damage assessment of a long composite wind turbine blade under extreme loading. Compos. Struct. 246, 112426 (2020)

Kam, T.Y., Su, H.M., Huang, C.Y.: Quasi-static buckling and first-ply failure loads of shear web reinforced glass-fabric composite wind blades. Compos. Struct. 160(Supplement C), 1225–1235 (2017)

Junjie, Y., Chenchen, C., Heng, C., Xiaonan, H., Baoquan, S., Shaohua, T., Xuefeng, C., Jianqiao, Y.: A multi-scale model for studying failure mechanisms of composite wind turbine blades. Compos. Struct. 212, 220–229 (2019)

Daniel, I.M., Daniel, S.M., Fenner, J.S.: A new yield and failure theory for composite materials under static and dynamic loading. Int. J. Solids Struct. 148–149, 79–93 (2018)

Rahimian, K., Seyed, S., Atefeh, K., Noorfaizal, Y., Michal, P., Reza, A.M., Nasir, T.M.: An energy-based concept for yielding of multidirectional frp composite structures using a mesoscale lamina damage model. Polymers 12, 1 (2020)

Xi, L., Dayou, M., Huifang, L., Wei, T., Xiaojing, G., Chao, Z., Yulong, L.: Assessment of failure criteria and damage evolution methods for composite laminates under low-velocity impact. Compos. Struct. 207, 727–739 (2019)

Martin, L., Overgaard, L.C.T., Thomsen, O.T., Erik, L., Daniel, I.M.: Investigation of failure mechanisms in gfrp sandwich structures with face sheet wrinkle defects used for wind turbine blades. Compos. Struct. 94(2), 768–778 (2012)

Wang, W.-X., Matsubara, T., Junfeng, H., Odahara, S., Nagai, T., Karasutani, T., Ohya, Y.: Experimental investigation into the influence of the flanged diffuser on the dynamic behavior of cfrp blade of a shrouded wind turbine. Renewable Energy 78, 386–397 (2015)

Megahed, M., Abo-bakr, R.M., Mohamed, S.A.: Optimization of hybrid natural laminated composite beams for a minimum weight and cost design. Compos. Struct. 239, 111984 (2020)

Jespersen, K.M., Mikkelsen, L.P.: Three dimensional fatigue damage evolution in non-crimp glass fibre fabric based composites used for wind turbine blades. Compos. Sci. Technol. 153, 261–272 (2017)

Amirzadeh, B., Louhghalam, A., Raessi, M., Tootkaboni, M.: A computational framework for the analysis of rain-induced erosion in wind turbine blades, part i: Stochastic rain texture model and drop impact simulations. J. Wind Eng. Ind. Aerodyn. 163, 33–43 (2017)

Kalagi, G.R., Patil, R., Nayak, N.: Experimental study on mechanical properties of natural fiber reinforced polymer composite materials for wind turbine blades. Materials Today: Proceedings, 5(1, Part 3):2588–2596, International Conference on Advanced Materials and Applications (ICAMA 2016), June 15–17, 2016. Bengaluru, Karanataka, INDIA (2018)

Kapil, S., Legesse, F., Kumar, R., Karunakaran, K.P.: Hybrid layered manufacturing of turbine blades. Materials Today: Proceedings, 4(8), 8837–8847, International Conference on Advancements in Aeromechanical Materials for Manufacturing (ICAAMM-2016): Organized by MLR Institute of Technology. Hyderabad, Telangana, India (2017)

Cárdenas, D., Elizalde, H., Marzocca, P., Gallegos, S., Probst, O.: A coupled aeroelastic damage progression model for wind turbine blades. Compos. Struct. 94(10), 3072–3081 (2012)

Maziz, A., Tarfaoui, M., Rechak, S., Nachtane, M., Gemi, L.: Finite element analysis of impact-induced damage in pressurized hybrid composites pipes. Int. J. Appl. Mech

Ammar, M., Mostapha, T., Lokman, G., Said, R., Mourad, N.: A progressive damage model for pressurized filament-wound hybrid composite pipe under low-velocity impact. Compos. Struct. 276, 114520 (2021)

Chen, X.: Experimental investigation on structural collapse of a large composite wind turbine blade under combined bending and torsion. Compos. Struct. 160, 435–445 (2017)

Xiao, C., Qin, Z., Ke, Y., Zhao Xiao, L., Jian Zhong, X.: Numerical analysis and experimental investigation of wind turbine blades with innovative features: Structural response and characteristics. Sci. China Technol. Sci. 58, 12 (2014)

de Freitas, P., Ricardo, L.U., Patrícia, F.G.B.: A revised theoretical analysis of aerodynamic optimization of horizontal-axis wind turbines based on bem theory. Renew. Energy 105(Supplement C), 625–636 (2017)

Wei-Cheng, W., Heng-Yi, T.: Life cycle assessment of small-scale horizontal axis wind turbines in Taiwan. J. Clean. Prod. 141(Supplement C), 492–501 (2017)

Xiong, L., Cheng, L., Gangqiang, L., Ajit, G., Yan, C.: Effects of aerodynamic damping on the tower load of offshore horizontal axis wind turbines. Appl. Energy 204(Supplement C), 1101–1114 (2017)

Chou, J.-S., Chiu, C.-K., Huang, I.-K., Chi, K.-N.: Failure analysis of wind turbine blade under critical wind loads. Eng. Failure Anal. 27, 99–118 (2013)

Lin, W., Athanasios, K., Takafumi, N., Pierre-Luc, D., Theodore, B.: Structural optimisation of vertical-axis wind turbine composite blades based on finite element analysis and genetic algorithm. Compos. Struct. 153(Supplement C), 123–138 (2016)

Koloor, S.S.R., Ayatollahi, M.R., Tamin, M.N.: Elastic-damage deformation response of fiber-reinforced polymer composite laminates with lamina interfaces. J. Reinforced Plastics Compos. 36(11), 832–849 (2017)

Tobias, W.-R., De Carvalho Nelson, V., Pinho, S.T.: A meso-scale simulation framework for predicting the mechanical response of triaxial braided composites. Compos. Part A Appl. Sci. Manuf. 107, 489–506 (2018)

Kupnik, M., Wygant, I.O., Khuri-Yakub, B.T.: Finite element analysis of stress stiffening effects in cmuts. pp. 487–490 (2008)

Genta, G., Silvagni, M.: On centrifugal softening in finite element method rotordynamics. J. Appl. Mech. 81, 011001 (2013)

Lahuerta, F., Koorn, N., Smissaert, D.: Wind turbine blade trailing edge failure assessment with sub-component test on static and fatigue load conditions. Compos. Struct. 204, 755–766 (2018)

Venkadesh, R., Monssef, D.-H., Laurent, G., Aghihad, K.: Numerical simulation analysis as a tool to identify areas of weakness in a turbine wind-blade and solutions for their reinforcement. Compos. Part B Eng. 103, 23–39 (2016)

Guangxing, W., Zhiwen, Q., Lei, Z., Ke, Y.: Strain response analysis of adhesively bonded extended composite wind turbine blade suffering unsteady aerodynamic loads. Eng. Failure Anal. 85, 36–49 (2018)

Sohouli, A., Yildiz, M., Suleman, A.: Cost analysis of variable stiffness composite structures with application to a wind turbine blade. Compos. Struct. 203, 681–695 (2018)

Xiao, C., Ulrich, H.P., Kim, B., Hjelm, M.S.: Effects of different material failures and surface contact on structural response of trailing edge sections in composite wind turbine blades. Compos. Struct. 226, 111306 (2019)

Xiao, C., Wei, Z., Zhao Xiao, L., Jian, Z.X.: Preliminary failure investigation of a 52.3m glass/epoxy composite wind turbine blade. Eng. Failure Anal. 44, 345–350 (2014)

Xiao, C., Peter, B., Hjelm, M.S., Kim, B., Sergei, S.: Understanding progressive failure mechanisms of a wind turbine blade trailing edge section through subcomponent tests and nonlinear fe analysis. Compos. Struct. 214, 422–438 (2019)

Wang, J. Huang, X., Wei, C., Zhang, L., Li, C., Liu, W.: Failure analysis at trailing edge of a wind turbine blade through subcomponent test. Eng. Failure Anal., p. 105596 (2021)

Sang-Lae, L.: Active vibration suppression of wind turbine blades integrated with piezoelectric sensors. Sci. Eng. Compos. Mater. 28(1), 402–414 (2021)

Hamdi, H.: Beam finite element model of a vibrate wind blade in large elastic deformation. Wind Struct. Int. J. 26, 01 (2018)

Dolinski, L., Krawczuk, M.: Analysis of modal parameters using a statistical approach for condition monitoring of the wind turbine blade. Appl. Sci. 10, p. 17 (2020)

Rafiee, R., Sharifi, P.: Stochastic failure analysis of composite pipes subjected to random excitation. Construct. Build. Mater. 224, 950–961 (2019)

Yilong, W., Dengqing, C., Jiaqi, P., Hao, C., Huagang, L., Wenhu, H.: Nonlinear random responses and fatigue prediction of elastically restrained laminated composite panels in thermo-acoustic environments. Compos. Struct. 229, 111391 (2019)

Zengwen, W., Yuan, Z., Jun, L., Maoqing, F., Guodong, F.: A frequency domain approach in residual stiffness estimation of composite thin-wall structures under random fatigue loadings. Int. J. Fatigue 124, 571–580 (2019)

Zhengwei Fan, Yu., Jiang, S.Z., Xun, C.: Experimental research on vibration fatigue of cfrp and its influence factors based on vibration testing. Shock Vibrat. 1–18(8), 2017 (2017)

International electrotechnical commission (iec) design standard, iec 61400-1 ed.3: Wind turbines - part 1: Design requirements

Germanischer-lloyd (gl) design standard, guideline for the certification of wind turbines edition. (2010)

Asl, M.E., Niezrecki, C., Sherwood, J., Avitabile, P.: Similitude analysis of thin-walled composite i-beams for subcomponent testing of wind turbine blades. Wind Eng. 41(5), 297–312 (2017)

Westerhuis, W., van Delden, S.H., van Dam, J.E.G., Pereira Marinho, J.P., Struik, P.C., Stomph, T.J.: Plant weight determines secondary fibre development in fibre hemp (cannabis sativa l). Ind. Crops Prod. 139, 111493 (2019)

Chizhi, Z., Fah, T.K.: Application of gamma process and maintenance cost for fatigue damage of wind turbine blade, Innovative Solutions for Energy Transitions. Energy Proc. 158, 3729–3734 (2019)

Nachtane, M., Tarfaoui, M., Ait Mohammed, M., Saifaoui, D., El Moumen, A.: Effects of environmental exposure on the mechanical properties of composite tidal current turbine. Renew. Energy 156, 1132–1145 (2020)

Shokrieh, M.M., Rafiee, R.: Simulation of fatigue failure in a full composite wind turbine blade. Compos. Struct. 74(3), 332–342 (2006)

Yeniceli, S.C.: Design optimization of whiffletree systems for wind turbine blade testing. PhD thesis, Middle East Technical University (2014)

Wind turbine blade testing solutions

Haselbach, P.: An advanced structural trailing edge modelling method for wind turbine blades. Compos. Struct. 180, 08 (2017)

Nachtane, M., Tarfaoui, M., El Moumen, A., Saifaoui, D.: Damage prediction of horizontal axis marine current turbines under hydrodynamic, hydrostatic and impacts loads. Compos. Struct. 170, 146–157 (2017)

ed Dîn, F., Saïf, B.T., Rajad, O., Kousksou, T., Arid, A., El Rhafiki, T., Jamil, A., Benbassou, A.: Cfd performance enhancement of a low cut-in speed current vertical tidal turbine through the nested hybridization of savonius and darrieus. Energy Convers. Manage. 169, 266–278 (2018)

Rajad, O., Hamid, M., Fertahi, S.E., Marjani, A.E.: Fiber orientation effect on the behavior of the composite materials of the horizontal axis wind turbine blade (hawtb). pp. 1–6 (2018)

ed Dîn, F., Saïf, B.T., Arid, A., Kousksou, T., Jamil, A., Moujibi, N., Benbassou, A.: Thermo-mechanical strength analysis for energy storage improvement of horizontal storage tanks integrating evacuated tube collectors. Int. J. Hydrogen Energy 42(49), 29370–29383 (2017)

Vu, V.D., Sheikh, A.H., Nguyen Giang, D., Luming, S.: A kinematically enhanced constitutive model for elastic and inelastic analysis of unidirectional fibre reinforced composite materials. Int. J. Mech. Sci. 126(Supplement C), 171–185 (2017)

Rao, S.S.: Chapter 8 - basic equations and solution procedure. In: Rao, Singiresu S. (ed.) The Finite Element Method in Engineering (Sixth Edition), pp. 295–330. Butterworth-Heinemann, sixth edition edition (2018)

Yingying, Z., Shanshan, X., Jigang, X., Qilin, Z.: Anisotropic mechanical properties and constitutive relations of ptfe coated glass fibers. Compos. Struct. 179(Supplement C), 601–616 (2017)

Hahn, H.T., Tsai, S.W.: Nonlinear elastic behavior of unidirectional composite laminae. J. Compos. Mater. 7(1), 102–118 (1973)

Lin, W.-P., Hsuan-Teh, H.: Nonlinear analysis of fiber-reinforced composite laminates subjected to uniaxial tensile load. J. Compos. Mater. 36(12), 1429–1450 (2002)

Lapczyk, I., Hurtado, J.A.: Progressive damage modeling in fiber-reinforced materials. Compos. Part A Appl. Sci. Manuf. 38(11), 2333–2341 (2007)

Ajer JRE: 3d finite element modeling of chip formation and induced damage in machining fiber reinforced composites (2015)

Swanson, S.R.: Introduction to Design and Analysis with Advanced Composite Materials. Prentice Hall, Hoboken (1997)

Gu, J., Chen, P.: Some modifications of Hashins failure criteria for unidirectional composite materials. Compos. Struct. 182(Supplement C), 143–152 (2017)

Zhang, C., Li, N., Wang, W., Binienda, W.K., Fang, H.: Progressive damage simulation of triaxially braided composite using a 3d meso-scale finite element model. Compos. Struct. 125, 104–116 (2015)

Tarfaoui, M., El Moumen, A., Lafdi, K.: Progressive damage modeling in carbon fibers/carbon nanotubes reinforced polymer composites. Compos. Part B Eng. 112, 185–195 (2017)

Camanho, P., Dávila, C.: Mixed-mode decohesion finite elements for the simulation of delamination in composite materials. 07 (2002)

Koloor, S.S.R., Reza, K.M., Hamzah, R.I.R., Tamin, M.N.: Fe model-based construction and progressive damage processes of frp composite laminates with different manufacturing processes. Int. J. Mech. Sci. 141, 223–235 (2018)

Sutherland, L.S.: A review of impact testing on marine composite materials: Part iii-damage tolerance and durability. Compos. Struct. 188, 512–518 (2018)

Dalli, D., Varandas, L.F., Catalanotti, G., Foster, S., Falzon, B.G.: Assessing the current modelling approach for predicting the crashworthiness of formula one composite structures. Compos. Part B Eng. 201, 108242 (2020)

Haselbach, P.U., Bitsche, R.D., Branner, K.: The effect of delaminations on local buckling in wind turbine blades. Renew. Energy 85, 295–305 (2016)

Kohnke, P.C.: Ansys. pp. 19–25 (1982)

Liu, F., Zhao, Y.: A hybrid method for analysing stationary random vibration of structures with uncertain parameters. Mech. Syst. Signal Process. 164, 108259 (2022)

Bishop, N., Sherratt, F.: Fatigue life prediction from power spectral density data ii: Recent developments. Environ. Eng. 2, 11–15 (1989)

Alessandro, C., Giuseppe, P., Francesco, F., Sergio, D.R.: A review of similitude methods for structural engineering. Appl. Mech. Rev. 71(3), 06030802 (2019)

Haibao, L., Falzon Brian, G., Dear John, P.: An experimental and numerical study on the crush behaviour of hybrid unidirectional/woven carbon-fibre reinforced composite laminates. Int. J. Mech. Sci. 164, 105160 (2019)

Ammar, M., Saïd, R., Mostapha, T.: Comparative study of tubular composite structure subjected to internal pressure loading: Analytical and numerical investigation. J. Compos. Mater. 55(11), 1517–1533 (2021)

Ullah, H.: Buckling of thin-walled cylindrical shells under axial compression. Int. J. Numer. Methods Eng. 79(11), 1332–1353 (2009)

Lee, S.H., Waas, A.: Compressive response and failure of fiber reinforced unidirectional composites. Int. J. Fract. 100, 12 (1999)

Pedro, R., Hamed, A., Andrzej, T., Jerzy, W.: A review on the mechanical behaviour of curvilinear fibre composite laminated panels. J. Compos. Mater. 48(22), 2761–2777 (2014)

Sayyad, A.S., Ghugal, Y.M.: Bending, buckling and free vibration of laminated composite and sandwich beams: A critical review of literature. Compos. Struct. 171, 486–504 (2017)

Sweep-twist design offers higher output at lower load

Ji, Y.M., Han, K.S.: Fracture mechanics approach for failure of adhesive joints in wind turbine blades. Renew. Energy 65, 23–28 (2014)

Xingjun, G., Yingxiong, L., Haitao, M., Gongfa, C.: Improving the overall performance of continuum structures: A topology optimization model considering stiffness, strength and stability. Comput. Methods Appl. Mech. Eng. 359, 112660 (2020)

Hassoon, O.H., Tarfaoui, M., El Moumen, A.: Progressive damage modeling in laminate composites under slamming impact water for naval applications. Compos. Struct. 167, 178–190 (2017)

Libin, Z., Tianliang, Q., Jianyu, Z., Yuli, C.: 3d gradual material degradation model for progressive damage analyses of unidirectional composite materials. Mathe. Probl. Eng. 1–11(05), 2015 (2015)

Philippidis, T.P., Antoniou, A.E.: A progressive damage fea model for glass/epoxy shell structures. J. Compos. Mater. 47(5), 623–637 (2013)

Koumpias, A.S., Tserpes, K.I.: Progressive damage modeling of 3d woven composites. Engineering Against Failure - Proceedings of the 3rd International Conference of Engineering Against Failure, ICEAF 2013, p. 6 (2013)

Acknowledgements

The authors are grateful for the funding support provided by EMISys Research Team, Engineering 3S Research Center, Mohammadia School of Engineers, University Mohammed V in Rabat, Morocco

Author information

Authors and Affiliations

Contributions

Omar Rajad: Conceptualization, Methodology, Software, Validation, Investigation, Visualization, Writing - original draft. Hamid Mounir and Abdellatif El Marjani: Methodology, Reviewing, Supervision

Corresponding author

Ethics declarations

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Conflict of interest

The authors declare that they have no conflict of interest.

Code Availability

Authors ensure that all relevant data are included in the article.

Ethics approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rajad, O., Mounir, H. & Marjani, A.E. Modeling, understanding and enhancing the mechanical response of the HAWTB composite structure through the nonlinear FE analysis of a proposed sub-model. Int J Interact Des Manuf 15, 631–659 (2021). https://doi.org/10.1007/s12008-021-00789-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-021-00789-7