Abstract

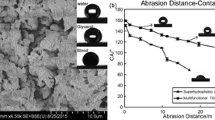

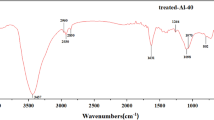

Titanium alloy-based superhydrophobic surfaces have great advantages in terms of self-cleaning and corrosion resistance. To extend the application of titanium alloy, a multifunctional superhydrophobic TA2 titanium alloy was fabricated by anodic oxidation and chemical modification. Regular TiO2 nanotube arrays were obtained after anodic oxidation and completely covered by 1H,1H,2H,2H-perfluorodecyltriethoxysilane. The water contact angle of superhydrophobic TA2 titanium alloy is as high as 153.4° ± 0.6°, and the contact angle of the surface shows good stability in different pH aqueous solutions and different concentrations of NaCl solutions. At −10 °C, the icing time of superhydrophobic TA2 titanium alloy surface can be extended to 4400 s. Furthermore, the superhydrophobic TA2 titanium alloy still maintains superhydrophobic properties when polished 70 times by sandpaper, indicating that the surface has good friction resistance. Electrochemical impedance spectroscopy results show that superhydrophobic TA2 titanium alloy with a Z′|f=0.01 Hz value of 84 kΩ cm2 has better corrosion resistance compared with the TA2 titanium alloy. These results indicate that the superhydrophobic composite film integrates multiple functions on the surface of TA2 titanium alloy, which greatly expands its application.

Similar content being viewed by others

References

Yi, W, Yao, L, “The Application of Titanium and Titanium Alloys on Foreign Vessels.” Ship Sci. Tech., 38 1–6 (2016)

Gao, F, Yu, W, Song, D, Gao, Q, Guo, L, Liao, Z, “Fracture Toughness of TA31 Titanium Alloy Joints Welded by Electron Beam Welding Under Constrained Condition.” Mater. Sci. Eng. A, 772 138612 (2020)

Pan, B, Cui, W, Shen, Y, Liu, T, “Further Study on the Ultimate Strength Analysis of Spherical Pressure Hulls.” Mar. Struct., 23 444–461 (2010)

Takahashi, K, Mori, K, Takebe, H, “Application of Titanium and Its Alloys for Automobile Parts.” MATEC Web Conf. EDP Sci., 321 02003 (2020)

Jiang, J, Ren, Z, Ma, Z, Zhang, T, Zhang, P, Zhang, DZ, Mao, Z, “Mechanical Properties and Microstructural Evolution of TA15 Ti Alloy Processed by Selective Laser Melting Before and After Annealing.” Mater. Sci. Eng. A, 772 138742 (2020)

Zuo, W, Yu, L, Lin, J, Yang, Y, Fei, Q, “Properties Improvement of Titanium Alloys Scaffolds in Bone Tissue Engineering: A Literature Review.” Ann. Transl. Med., 9 15 (2021)

Dong, H, “Tribological Properties of Titanium-Based Alloys.” In Surf. Eng. Light Alloys, pp. 58–80. Elsevier (2010)

Wang, S, Liao, Z, Liu, Y, Liu, W, “Different tribological Behaviors of Titanium Alloys Modified by Thermal Oxidation and Spraying Diamond like Carbon.” Surf. Coat. Tech., 252 64–73 (2014)

Auwal, ST, Ramesh, S, Yusof, F, Manladan, SM, “A Review on Laser Beam Welding of Titanium Alloys.” Int. J. Adv. Manuf. Tech, 97 1071–1098 (2018)

Singh, H, Kumar, R, Prakash, C, Singh, S, “HA-Based Coating by Plasma Spray Techniques on Titanium Alloy for Orthopedic Applications.” Mater. Today: Proc., 50 612–628 (2022)

Diamanti, MV, Curto, BD, Pedeferri, M, “Anodic Oxidation of Titanium: From Technical Aspects to Biomedical Applications.” J. Appl. Biomater. Biom., 9 55–69 (2011)

Dalawai, SP, Aly, MAS, Latthe, SS, Xing, R, Sutar, RS, Nagappan, S, Ha, CS, Sadasivuni, KK, Liu, S, “Recent Advances in Durability of Superhydrophobic Self-Cleaning Technology: A Critical Review.” Prog. Org. Coat., 138 105381 (2020)

Chao, Q, Meng, L, Shuxian, C, “Anti-Icing Characteristics of PTFE Super Hydrophobic Coating on Titanium Alloy Surface.” J. Alloys Compd., 860 157907 (2021)

Long, J, Fan, P, Gong, D, Jiang, D, Zhang, H, Li, L, Zhong, M, “Superhydrophobic Surfaces Fabricated by Femtosecond Laser with Tunable Water Adhesion: From Lotus Leaf to Rose Petal.” ACS Appl. Mater. Interfaces, 7 9858–9865 (2015)

Peng, C, Chen, Z, Tiwari, M, “All-Organic Superhydrophobic Coatings with Mechanochemical Robustness and Liquid Impalement Resistance.” Nat. Mater., 17 355–360 (2018)

Ruan, M, Li, W, Wang, B, Deng, B, Ma, F, Yu, Z, “Preparation and Anti-Icing Behavior of Superhydrophobic Surfaces on Aluminum Alloy Substrates.” Langmuir, 29 8482–8491 (2013)

Rodič, P, Kapun, B, Panjan, M, Milošev, I, “Easy and Fast Fabrication of Self-Cleaning and Anti-Icing Perfluoroalkyl Silane Film on Aluminium.” Coatings, 10 234 (2020)

Hosseinabadi, HN, Sajjady, SA, Amini, S, “Creating Micro Textured Surfaces for the Improvement of Surface Wettability Through Ultrasonic Vibration Assisted Turning.” Int. J. Adv. Manuf. Tech., 96 2825–2839 (2018)

Gao, X, Tong, W, Ouyang, X, Wang, X, “Facile Fabrication of a Superhydrophobic Titanium Surface with Mechanical Durability by Chemical Etching.” RSC Adv., 5 84666–84672 (2015)

Belaud, C, Vercillo, V, Kolb, M, Bonaccurso, E, “Development of Nanostructured Icephobic Aluminium Oxide Surfaces for Aeronautic Applications.” Surf. Coat. Technol., 405 126652 (2021)

Laroche, A, Bottone, D, Seeger, S, Bonaccurso, E, “Silicone Nanofilaments Grown on Aircraft Alloys for Low Ice Adhesion.” Surf. Coat. Technol., 410 126971 (2021)

Li, T, Dong, C, Liu, Y, Wu, J, Zhang, X, Gong, X, Wei, Zhao, Wang, D, Zhu, D, “An Anodized Titanium/Sol-Gel Composite Coating with Self-Healable Superhydrophobic and Oleophobic Property.” Front. Mater., 8 618674 (2021)

Wang, G, Liu, S, Wei, S, Liu, Y, Lian, J, Jiang, Q, “Robust Superhydrophobic Surface on Al Substrate with Durability, Corrosion Resistance and Ice-Phobicity.” Sci. Rep., 6 20933 (2016)

Xiang, G, Lia, S, Maa, B, “Optimal Condition for Preparing TiO2 Superhydrophobic Surfaces on Titanium Substrate in NH4F/H3PO4 Electrolyte by Anodization and Its Self-Cleaning Effect and Anti-Icing Ability.” Surf. Coat. Technol., 423 127574 (2021)

Olkowicz, K, Kowalczyk, K, Buczko, Z, Czwartos, J, Nasiłowska, B, “Durability and Additional Properties of Anodized Aluminum-Based Coatings with Different Wettability Under Natural Conditions.” Materials, 16 3729 (2023)

Zhang, J, Wang, J, Zhang, B, Zeng, Y, Duan, J, Hou, B, “Fabrication of Anodized Superhydrophobic 5083 Aluminum Alloy Surface for Marine Anti-Corrosion and Anti-Biofouling.” J. Oceanol. Limnol., 38 1246–1255 (2020)

Gurera, D, Bhushan, B, “Fabrication of Bioinspired, Self-Cleaning, Anti-Icing, Superliquiphilic/Phobic Titanium Using Different Pathways.” Philos. Trans. R. Soc. Lond. Ser. A, 377 20180273 (2019)

Xua, Y, Liu, M, “Soiling and Corrosion Behaviors on Fluorinated Anodized TiO2 Surface Infusedbyperfluoropolyether.” Surf. Coat. Technol., 307 332–344 (2016)

Zhang, X, Wan, Y, Ren, B, Wang, H, Yu, M, Liu, A, Liu, Z, “Preparation of Superhydrophobic Surface on Titanium Alloy via Micro-Milling, Anodic Oxidation and Fluorination.” Micromachines, 11 316 (2020)

Wang, Y, Chen, J, Yang, Y, Liu, Z, Wang, H, He, Z, “Nanostructured Superhydrophobic Titanium-Based Materials: A Novel Preparation Pathway to Attain Superhydrophobicity on TC4 Alloy.” Nanomaterials, 12 2086 (2022)

Liu, R, Chi, Z, Cao, L, Weng, Z, Wang, L, Li, L, Saeeda, S, Lian, Z, Wang, Z, “Fabrication of Biomimetic Superhydrophobic and Anti-icing Ti6Al4V Alloy Surfaces by Direct Laser Interference Lithography and Hydrothermal Treatment.” Appl. Surf. Sci., 534 147576 (2020)

Sato, M, Watanabe, H, Furusawa, T, Suzuki, N, “The Degradation of Perfluorinated Organic Thin Film during XPS Measurement.” J. Surf. Anal., 12 (2) 183–187 (2005)

Liu, H, Chen, GC, Du, LZ, Lan, H, Huang, CB, Wang, BL, Zhang, HY, Zhang, WG, “Preparation and Characterization of Titanium Alloy Protective Coating.” Rare Metal Mat. Eng., 47 647–651 (2018)

Zhou, X, Ouyang, C, “Anodized Porous Titanium Coated with Ni-CeO2 Deposits for Enhancing Surface Toughness and Wear Resistance.” Appl. Surf. Sci., 405 476–488 (2017)

Su, F, Yao, K, “Facile Fabrication of Superhydrophobic Surface with Excellent Mechanical Abrasion and Corrosion Resistance on Copper Substrate by a Novel Method.” ACS Appl. Mater. Interfaces, 6 8762–8770 (2014)

Wermuth, L, Kolb, M, Mertens, T, Strobl, T, Raps, D, “Superhydrophobic Surfaces Based on Self-Organized TiO2-Nanotubes.” Prog. Org. Coat., 87 242–249 (2015)

Zhu, B, Liu, J, Chen, Y, Liu, Y, Yang, Z, Zhang, Z, “Superhydrophobic Coating with Multiscale Structure Based on Crosslinked Silanized Polyacrylate and Nanoparticles.” Surf. Coat. Technol., 331 40–47 (2017)

Xiang, G, Li, S, Ma, B, “Optimal Condition for Preparing TiO2 Superhydrophobic Surfaces on Titanium Substrate in NH4F/H3PO4 Electrolyte by Anodization and Its Self-Cleaning Effect and Anti-icing Ability.” Surf. Coat. Technol., 423 127574 (2021)

Zheng, S, Li, C, Fu, Q, Xiang, T, Hu, W, Wang, J, Ding, S, Liu, P, Chen, Z, “Fabrication of a Micro-Nanostructured Superhydrophobic Aluminum Surface with Excellent Corrosion Resistance and Anti-Icing Performance.” RSC Adv., 6 79389–79400 (2016)

Li, J, Liu, Q, Wang, Y, Chen, R, Takahashi, K, Li, R, Liu, L, Wang, J, “Formation of a Corrosion-Resistant and Anti-Icing Superhydrophobic Surface on Magnesium Alloy via a Single-Step Method.” J. Electrochem. Soc., 163 C213 (2016)

Jiang, C, Li, W, “A Facile Method for Preparations of Micro-Nanotextured Co3O4 Films with the Excellent Superhydrophobic and Anti-Icing Behavior.” Mater. Lett., 122 133–138 (2014)

Li, W, Zhan, Y, Yu, S, “Applications of Superhydrophobic Coatings in Anti-Icing: Theory, Mechanisms, Impact Factors, Challenges and Perspectives.” Prog. Org. Coat., 152 106117 (2021)

Alizadeh, A, Yamada, M, Li, R, Shang, W, Otta, S, Zhong, S, Ge, L, Dhinojwala, A, Conway, K, Bahadur, V, Vinciquerra, A, Stephens, B, Blohm, M, “Dynamics of Ice Nucleation on Water Repellent Surfaces.” Langmuir, 28 3180–3186 (2012)

Zhang, Y, Anim-Danso, E, Bekele, S, Dhinojwala, A, “Effect of Surface Energy on Freezing Temperature of Water.” ACS Appl. Mater. Interfaces, 8 17583–17590 (2016)

Li, C, Cao, Z, Xie, C, Li, Z, Fang, X, Ou, J, Xue, M, Wang, F, Lei, S, Li, W, “Facile Preparation of TiO2/Acrylic Resin Superhydrophobic Surface with Excellent Wear Resistance.” J. Appl. Polym. Sci., 136 47762 (2019)

Yamauchi, Y, Tenjimbayashi, M, Samitsu, S, Naito, M, “Durable and Flexible Superhydrophobic Materials: Abrasion/Scratching/Slicing/Droplet Impacting/Bending/Twisting-Tolerant Composite with Porcupinefish-Like Structure.” ACS Appl. Mater. Interfaces, 11 32381–32389 (2019)

Wang, N, Tang, L, Tong, W, Xiong, D, “Fabrication of Robust and Scalable Superhydrophobic Surfaces and Investigation of Their Anti-Icing Properties.” Mater. Des., 156 320–328 (2018)

Ashish, B, Saini, J, Sharma, B, “A Review of Tool Wear Prediction during Friction Stir Welding of Aluminium Matrix Composite.” T. Nonferr. Metal. Soc., 26 2003–2018 (2016)

Yuan, C, Guo, Z, Tao, W, Dong, C, Bai, X, “Effects of Different Grain Sized Sands on Wear Behaviours of NBR/Casting Copper Alloys.” Wear, 384 185–191 (2017)

Murray, TJ, “Poly(Amide-Imides): Wire Enamels with Excellent Thermal and Chemical Properties.” Macromol. Mater. Eng., 293 350–360 (2008)

Tian, X, Verho, T, Ras, RHA, “Moving Superhydrophobic Surfaces Toward Real-World Applications.” Science, 352 142–143 (2016)

Xu, J, Wang, GD, Lu, X, Liu, L, Munroe, P, Xie, Z, “Mechanical and Corrosion-Resistant Properties of Ti-Nb-Si-N Nanocomposite Films Prepared by a Double Glow Discharge Plasma Technique.” Ceram. Int., 40 8621–8630 (2014)

Doshi, DA, Shah, PB, Singh, S, Branson, ED, Malanoski, AP, Watkins, EB, Majewski, J, Swol, FV, Brinker, CJ, “Investigating the Interface of Superhydrophobic Surfaces in Contact with Water.” Langmuir, 21 7805–7811 (2005)

Acknowledgments

The authors thank the financial support from the National Natural Science Foundation of China (Project 52171083, 52001300), Natural Science Foundation of Zhejiang Province (Grant No. LQ20B020011) and the Public Welfare Projects of Zhejiang Province (Grant No. LGG22E010002).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by SC, BZ, XW, GJ, SS, and JC, NC, ML, YY, LR, and LJ. The first draft of the manuscript was written by SC, BZ, and GW. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, S., Zhu, B., Wang, X. et al. Fabrication of superhydrophobic TA2 titanium alloy and preliminary assessment of its antifouling, self-cleaning, anti-icing, friction resistance, and corrosion resistance performance. J Coat Technol Res (2024). https://doi.org/10.1007/s11998-023-00900-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11998-023-00900-5