Abstract

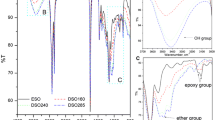

A long oil alkyd was formulated with three soybean oil-based reactive diluents. Coatings properties were evaluated as a function of concentration of reactive diluent in the formulation. The tensile, thermomechanical, and general coating properties were evaluated. General coatings properties included crosshatch adhesion, pencil hardness, impact resistance, and solvent resistance. The siloxane and allyl ether-functionalized soybean oil enhanced the tensile modulus and crosslink density by 20% and 70%, respectively. Coatings with fluorine-functionalized soybean oil showed enhanced contact angle and solvent resistance, compared to alkyd coatings alone. The incorporation of reactive diluents in the formulation improved pencil hardness, while other general coating properties were not significantly affected.

Similar content being viewed by others

References

Seymour, RB, “History of the Development and Growth of Thermosetting Polymers.” J. Macromol. Sci. Chem., 15 (6) 1165–1171 (1981)

Wicks, ZW, Jr, Jones, FN, Peter Pappas, S, Douglas, A, Wicks, Organic Coatings: Science and Technology. Wiley, Hoboken, 2007

Kim, YM, Harrad, S, Harrison, RM, “Concentrations and Sources of VOCs in Urban Domestic and Public Microenvironments.” Environ. Sci. Technol., 35 (6) 997–1004 (2001)

Yu, C, Crump, D, “A Review of the Emission of VOCs from Polymeric Materials Used in Buildings.” Build. Environ., 33 (6) 357–374 (1998)

Lindeboom, J, “Air-Drying High Solids Alkyd Pants for Decorative Coatings.” Prog. Org. Coat., 34 (1) 147–151 (1997)

Weiss, KD, “Paint and Coatings: A Mature Industry in Transition.” Prog. Polym. Sci., 22 (2) 203–245 (1997)

Zabel, KH, Klaasen, RP, Muizebelt, WJ, Gracey, BP, Hallett, C, Brooks, CD, “Design and Incorporation of Reactive Diluents for Air-Drying High Solids Alkyd Paints.” Prog. Org. Coat., 35 (1) 255–264 (1999)

Muizebelt, WJ, Hubert, JC, Nielen, MWF, Klaasen, RP, Zabel, KH, “Crosslink Mechanisms of High-Solids Alkyd Resins in the Presence of Reactive Diluents.” Prog. Org. Coat., 40 (1) 121–130 (2000)

Samuelsson, J, Sundell, PE, Johansson, M, “Synthesis and Polymerization of a Radiation Curable Hyperbranched Resin Based on Epoxy Functional Fatty Acids.” Prog. Org. Coat., 50 (3) 193–198 (2004)

Ohlsson, K, Bergman, T, Sundell, PE, Deltin, T, Tran, I, Svensson, M, Johansson, M, “Novel Coil Coating Systems Using Fatty Acid Based Reactive Diluents.” Prog. Org. Coat., 73 (4) 291–293 (2012)

Johansson, K, Johansson, M, “Fatty Acid Methyl Ester as Reactive Diluent in Thermally Cured Solvent-Borne Coil-Coatings—The Effect of Fatty Acid Pattern on the Curing Performance and Final Properties.” Prog. Org. Coat., 63 (2) 155–159 (2008)

Johansson, K, Johansson, M, “The Effect of Fatty Acid Methyl Esters on the Curing Performance and Final Properties of Thermally Cured Solvent-Borne Coil Coatings.” Prog. Org. Coat., 59 (2) 146–151 (2007)

Johansson, K, Johansson, M, “Fatty Acid Methyl Esters as Reactive Diluents in Coil Coatings.” Polym. Prepr, 48 857–858 (2007)

Johansson, K, Johansson, M, “A Model Study on Fatty Acid Methyl Esters as Reactive Diluents in Thermally Cured Coil Coating Systems.” Prog. Org. Coat., 55 (4) 382–387 (2006)

Muturi, P, Wang, D, Dirlikov, S, “Epoxidized Vegetable Oils as Reactive Diluents I. Comparison of Vernonia, Epoxidized Soybean and Epoxidized Linseed Oils.” Prog. Org. Coat., 25 (1) 85–94 (1994)

Biermann, U, Bornscheuer, U, Meier, MA, Metzger, JO, Schäfer, HJ, “Oils and Fats as Renewable Raw Materials in Chemistry.” Angew. Chem. Int. Ed., 50 (17) 3854–3871 (2011)

Crivello, JV, Narayan, R, “Epoxidized Triglycerides as Renewable Monomers in Photoinitiated Cationic Polymerization.” Chem. Mater., 4 (3) 692–699 (1992)

Bruson, HA, “Esters of Hydroxydihydronorpolycyclopentadienes and Unsaturated Fatty Acids.” U.S. Patent No. 2,414,089 14 January 1947

Chen-shang, FJ, “Air-Drying Esters of 1,3-Cyclic Acetals.” U.S. Patent No. 3,184,441 18 May 1965

Enomoto, S, Nishida, HTS, Wada, H, Mukaida, Y, Yanaka, M, “Study of Reactive Diluent for Air-Dried Alkyd Paint.” J. Appl. Polym. Sci., 22 (1) 253–265 (1978)

Bhabhe, MD, Athawale, VD, “Chemoenzymatic Synthesis of Oil-Modified Acrylic Monomers as Reactive Diluents for High Solids Coatings.” Prog. Org. Coat., 30 (4) 207–211 (1997)

Wutticharoenwong, K, Soucek, MD, “Synthesis of Tung-Oil-Based Reactive Diluents.” Macromol. Mater. Eng., 295 (12) 1097–1106 (2010)

Wutticharoenwong, K, Dziczkowski, J, Soucek, MD, “Tung Based Reactive Diluents for Alkyd Systems: Film Properties.” Prog. Org. Coat., 73 (4) 283–290 (2012)

Nalawade, PP, Mehta, B, Pugh, C, Soucek, MD, “Modified Soybean Oil as a Reactive Diluent: Synthesis and Characterization.” J. Polym. Sci., Part A: Polym. Chem., 52 (21) 3045–3059 (2014)

Quirino, RL, Larock, RC, “Rh-Based Biphasic Isomerization of Carbon-Carbon Double Bonds in Natural Oils.” J. Am. Oil Chem. Soc., 89 (6) 1113–1124 (2012)

Wicks, ZW, Jones, FN, Pappas, SP, Organic Coatings Science and Technology, Vol. II, Application, Properties, and Performance. Wiley, New York, 1992

Soucek, MD, Khattab, T, Wu, J, “Review of Autoxidation and Driers.” Prog. Org. Coat., 73 (4) 435–454 (2012)

Choe, E, Min, DB, “Mechanisms and Factors for Edible Oil Oxidation.” Compr. Rev. Food Sci. Food Saf., 5 (4) 169–186 (2006)

Muizebelt, WJ, Hubert, JC, Venderbosch, RAM, “Mechanistic Study of Drying of Alkyd Resins Using Ethyl Linoleate as a Model Substance.” Prog. Org. Coat., 24 (1) 263–279 (1994)

Brinker, CJ, Scherer, GW (eds.), Sol-Gel Science: The Physics and Chemistry of Sol-Gel Processing. Gulf Professional Publishing, Houston, 1990

Chattopadhyay, DK, Panda, SS, Raju, KVSN, “Thermal and Mechanical Properties of Epoxy Acrylate/Methacrylates UV Cured Coatings.” Prog. Org. Coat., 54 (1) 10–19 (2005)

Núñez-Regueira, L, Villanueva, M, Fraga-Rivas, I, “Effect of a Reactive Diluent on the Curing and Dynamomechanical Properties of an Epoxy-Diamine System.” J. Therm. Anal. Calorim., 86 (2) 463–468 (2006)

Nam, KH, Lee, TH, Bae, BS, Popall, M, “Condensation Reaction of 3-(Methacryloxypropyl)-Trimethoxysilane and Diisobutylsilanediol in Non-hydrolytic Sol-Gel Process.” J. Sol-Gel. Sci. Technol., 39 (3) 255–260 (2006)

ASTM Designation: D 3359—97, Standard Test Methods for Measuring Adhesion by Tape Test

Grainger, DW, Stewart, CW, Fluorinated Coatings and Films: Motivation and Significance. (2001)

Van de Grampel, RD, Ming, W, Van Gennip, WJH, Van der Velden, F, Laven, J, Niemantsverdriet, JW, Van der Linde, R, “Thermally Cured Low Surface-Tension Epoxy Films.” Polymer, 46 (23) 10531–10537 (2005)

http://www.ers.usda.gov/topics/crops/soybeans-oil-crops/background.aspx#.VCIyFPldVog

https://www.hort.purdue.edu/newcrop/duke_energy/Aleurites_fordii.html#Cultivation

Trey, SM, Nilsson, C, Malmström, E, Johansson, M, “Thiol-ene Networks and Reactive Surfaces via Photoinduced Polymerization of Allyl Ether Functional Hyperbranched Polymers.” Prog. Org. Coat., 68 (1) 151–158 (2010)

Das, G, Karak, N, “Epoxidized Mesua ferrea L. Seed Oil-Based Reactive Diluent for BPA Epoxy Resin and Their Green Nanocomposites.” Prog. Org. Coat., 66 (1) 59–64 (2009)

Ghorui, S, Bandyopadhyay, NR, Ray, D, Sengupta, S, Kar, T, “Use of Maleated Castor Oil as Biomodifier in Unsaturated Polyester Resin/Fly Ash Composites.” Ind. Crops Prod., 34 (1) 893–899 (2011)

Barbosa, JV, Veludo, E, Moniz, J, Magalhães, FD, Bastos, MM, “Synthesis and Characterization of Acrylic Fatty Acid Derivative and Use as Reactive Coalescing Agent.” Eur. J. Lipid Sci. Technol., 114 (10) 1175–1182 (2012)

Barbosa, JV, Oliveira, F, Moniz, J, Magalhães, FD, Bastos, MM, “Synthesis and Characterization of Allyl Fatty Acid Derivatives as Reactive Coalescing Agents for Latexes.” J. Am. Oil Chem. Soc., 89 (12) 2215–2226 (2012)

Acknowledgments

The authors thank the Ohio Soybean Council for funding this research. The experimental support provided by the University of Akron Magnetic Resonance Center and Jessi Baughman is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nalawade, P.P., Soucek, M.D. Modified soybean oil as a reactive diluent: coating performance. J Coat Technol Res 12, 1005–1021 (2015). https://doi.org/10.1007/s11998-015-9691-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-015-9691-2