Abstract

Table olives are the most important fermented vegetable in the Mediterranean countries. In a continuous effort to improve the quality of this food, this work applies an experimental design with four variables to study the use of 1-methylcyclopropene (1-MCP, 2.85 µL/L) in combination with a light heat shock (65 °C, 5 min) and dimethyl dicarbonate (DMDC, 83 mg/L), during the processing of Spanish style and natural table olives. Fruits processed in the Spanish style exhibited higher moisture levels, luminance, and combined acidity. On the contrary, natural olives contained more sugars, had a firmer texture, and displayed a greener colour. Our results show that applying 1-MCP, heat shock, and DMDC can positively impact the processing of Spanish style and natural table olives and influence their physicochemical characteristics. Adding DMDC to the initial brine caused colour degradation but lowered the pH. Using 1-MCP with a light heat shock improved the sugar content and luminance of olives and increased the titratable acidity in the brine. Applying 1-MCP to the Spanish style enhanced the luminosity (brightness) and, when combined with DMDC, led to the lowest pH levels. Further research at an industrial scale is necessary to validate these results and study their influence on microorganisms. These treatments could have applications in developing new table olive processing methods that allow for more predictable products.

Similar content being viewed by others

Introduction

Horticultural commodities such as fruits and vegetables are highly perishable and susceptible to significant qualitative and quantitative losses. Various techniques are employed to mitigate these losses, such as using cold and controlled or modified atmospheric storage, where specific proportions of gases replace the air (Chhetri et al., 2022).

A key factor contributing to the deterioration and perishability of fruits and vegetables is ethylene, a plant hormone that regulates various physiological processes in plants. Ethylene is associated with accelerated ripening, moisture loss, softening, senescence, and spoilage. Ethylene production varies among horticultural crops, with apples, apricots, peaches or mammee apples, and cherimoyas classified as high or very high ethylene producers. In contrast, olives produce low levels of ethylene (0.1–1.0 μL/kg/h at 20 °C) (Lata & Sujayasree, 2021).

It was not until 1962 that researchers Burg and Burgs (1962) recognized that modified atmospheres reduced respiration and inhibited ethylene production and action. The discovery led to further research efforts to identify ethylene-binding sites and develop compounds that could deactivate them. Among the various approaches explored, the strategy employed by Sisler and coworkers (1996) ultimately led to the discovery of the highly effective compound known as 1-methylcyclopropene (1-MCP). Developing a powdered cyclodextrin-bound formulation provided a convenient way to commercialize the product, as Daly and Kourelis (2001) described. By blocking the corresponding receptors, 1-MCP inhibits the hormonal effects of ethylene (Fang & Wakisaska, 2021).

Numerous publications have documented the many beneficial and limited adverse effects of 1-MCP on fruits and vegetables, especially apples, which require relatively simple application techniques. For a comprehensive overview of the current applications of 1-MCP, interested readers can refer to the work by Vilhena and others (2023). Most of the applications of 1-MCP are designed for climacteric fruits (Satekge & Magwaza, 2022). However, it is worth noting that this compound is also utilized for non-climacteric fruits (Li et al., 2016). The concentration of 1-MCP usually decreases markedly with time, and the expected potential levels of exposure to impurities are so low as to be generally recognized as no safety concern. In Spain, its use is authorized for several fruits (Ministerio de Agricultura Pesca y Alimentación, 2007).

Although olives are generally considered non-climacteric fruits, they can still deteriorate and change, such as peel alterations, loss of flesh hardness, anaerobiosis stimulation, and decay development. Ramin (2007) conducted a study to assess the effectiveness of 1-MCP in preserving the post-harvesting quality of green olives. They applied various concentrations of 1-MCP (0.45, 0.9, or 1.8 μL/L) and observed that the treatment significantly reduced softening and delayed surface colour changes. The best results were obtained with concentrations of 0.9–1.8 μL/L, which extended the storage period of green olives from 60 to 105 days at 5 °C (optimum temperature for olives). A subsequent study by Amini and Ramin (2015) examined the effect of 1-MCP treatment (1.8 μL/L) on Manzanilla and Mission cultivars harvested at the mature green stage. The treated fruits were then immersed in CaCl2 solutions (0–100 mM) for 2 h at a pressure of 1.2 bar. The combined treatment of 1-MCP and CaCl2 improved hardness and colour retention and minimized damage during 84 days of storage at 6 °C.

However, it is worth noting that other studies found that ethylene treatment of olive fruits (specifically Konservolia cv.), harvested shortly before reaching the green maturation and exposed to 20 °C for 5 days, tended to increase hardness in a non-climacteric concentration-dependent manner. Interestingly, all ethylene inhibitors, including 1-MCP, applied before ethylene treatment cancelled the firmness improvement. The effect of ethylene on firmness was attributed to changes in cell wall composition and structure. In another study, the post-harvesting treatment of olive fruits with 1-MCP influenced the maturation process and enhanced the sensory and commercial quality of the fermented fruits without affecting microbiological evolution (López-García et al., 2022). Nonetheless, the role of 1-MCP in post-harvested table olives still requires further clarification, especially in combination with other treatments.

Dimethyl dicarbonate (DMDC) is a disinfectant (Chen et al., 2013) with numerous applications in fermented products. Yu et al. (2014) used this compound in the fermentation of litchi juice as an alternative to heat treatment. Zhang et al. (2022) also applied this compound during the fermentation of melon spirits, improving the aroma. DMDC can be used in addition to sulphur dioxide to control the growth of microorganisms in wine (Costa et al., 2008). In terms of safety, the EFSA Panel on Food Additives and Nutrient Sources Added to Food (ANS) (2015) has recently issued a scientific opinion following the latest re-evaluation of DMDC (E-242) as a food additive. According to it, no evidence suggests any safety concerns associated with its use. To our knowledge, DMDC has yet to be applied during table olive processing.

On the contrary, applying a slight heat shock after olive harvesting has been previously studied. Heat-shocked was a convenient procedure for ridding the fruits of naturally occurring interfering and competitive microbial groups, but it also made the olives highly fermentable (Etchells et al., 1966). Balatsouras et al. (1983) also reported a slight improvement in fermentability using a heat-shock treatment applied to Conservolea green olives. Recently, Rodríguez-Gómez et al. (2017) noticed a small beneficial effect on the fresh green and cured presentations of directly green Aloreña de Málaga table olives. The impact on fruits following the traditional process was especially relevant, enhancing the lactic acid fermentation, retaining the green appearance, giving them higher stability after packaging, and leading to elevated sensory scores. Ramírez et al. (2017) also applied a mild heat treatment to olives, followed by a direct brining and inoculation with selected lactic acid bacteria (LAB) strains. The process reduced the natural bitterness of fruits and caused oleuropein depletion without applying any alkali hydrolysis. The heat treatment inactivated the β-glucosidase activity of fruits and prevented the formation of antimicrobial compounds like the dialdehydic form of elenolic acid linked to hydroxytyrosol (HyEDA).

This study investigates the impact of various pre-treatments, including 1-MCP application, slight heat shock, processing methods (Spanish style or directly brined), and DMDC addition, on the physicochemical properties of fruits and brines at the end of the fermentative process of table olives, as primary interest for consumers. Besides, the research examines the overall progression of the fruits and brine parameters by monitoring their responses as the area under their respective curves over the fermentative process, which information holds particular significance for processors.

Material and Methods

Raw Material and Experimental Design

For the experiment, four variables at two levels were considered (A, use or not of 1-MCP; B, application or not of a heat shock treatment; C, type of green olive processing style, lye treated Spanish style (ES) or natural (Nat); and D, use or not of DMDC). A complete factorial experiment design with two replicates would have included 32 runs (16 treatments * 2 duplicates). However, logistic limitations made it necessary to reduce the experimental design to only 8 combinations of variables + 2 replicated treatments (to estimate pure error), as described in Fig. 1, making 10 runs. A summary of the experimental design appropriate for the statistical analyses is presented in Table S1 (Supplementary Material).

Scheme of the experimental design used in this work, displaying the various processing steps and treatments administered to each fermenter container. A summarized version for statistical analysis can also be found in Table S1 (Supplementary Material)

Eighty kilograms of Manzanilla fruits were hand-harvested in Huevar del Aljarafe (Seville, Spain) at the green ripening stage (mid-October 2021) and transported at 25 °C to the Instituto de la Grasa (CSIC, Seville, Spain) laboratory in less than 1 h. Half of the lot was subjected to 1-MCP treatment (2.85 µL/L) in a closed container (220 L volume) at 25 °C for 20 h, following the manufacturer’s recommendations (AgroFresh Ibérica, Lleida, Spain). The other half was maintained in the air atmosphere for the same time and temperature.

Each one of the two fruit lots (approx. 40 kg of 1-MCP treated and untreated olives) was, in turn, subdivided into two other subplots. Subsequently, two subplots (one of 1-MCP olives and another of non-treated olives) were subjected to a heat shock in water at 65 °C for 5 min following the protocol described by Rodríguez-Gómez et al. (2017), while the other two remained untreated. Afterwards, half of the olives from each of the four subplots were processed as Spanish style (ES), while the other half were directly brined (Nat) olives.

The Spanish style fruits (ES) were treated with a 1.5% (heat shock fruits) or 2.0% (untreated heat shock fruits) NaOH solution for 4.5 h, reaching the lye 2/3 flesh thickness. Then, fruits were washed (3 h) to remove excess alkali and brined in an 11% (w/v) NaCl solution with 0.37% (v/v) HCl. In the case of natural processing (Nat), olives were washed with tap water to remove impurities and directly brined in a 5% NaCl solution. Fermentations were carried out in 8 L-volume containers with 4.3 kg of olives and 2.8 L of brine. Two days after brining, selected containers (see Fig. 1) were treated with 83 mg/L of DMDC (Duessel H Limited, Hong Kong). All fermentations were inoculated on the 7th day of processing with the commercial inocula OleicaStarter Advance (TAFIQS in Foods, Seville, Spain), a mix of three strains of Lactiplantibacillus pentosus species, and OleicaStarter Yeast (TAFIQS in Foods), a blend of the yeast Wickerhamomyces anomalus and Saccharomyces cerevisiae, following manufacturer’s recommendations.

Samples of 0.5 kg olives were withdrawn from fresh fruits and at the two levels of the variables after each treatment. Besides, changes in the physicochemical characteristics of fruits and brines during fermentation were also monitored, as described below.

Physicochemical Analysis

Olive brines from the 10 fermentation vessels were periodically sampled in duplicates (2, 5, 7, 13, 25, 40, 60, 104, and 181 days) during fermentation to determine pH, titratable acidity (expressed as g of lactic/100 mL of brine) and combined acidity (expressed as mEq of HCL acid required to reach pH 2.6 in 1L brine), using an automatic titrator Rondolino model (Mettler Toledo, Barcelona, Spain). Sodium chloride (NaCl, g/100 mL or w/v percentage) was also evaluated by volumetric analysis. The methods described by Garrido-Fernández et al. (1997) were used for these determinations. Briefly, fermentation vessels were homogenized before sampling, and 50 mL of brine was extracted. Forty milliliters of brines were used for the determination of pH, titratable acidity, and combined acidity. Sodium chloride content was assessed through titration using silver nitrate and potassium dichromate. For this, 0.5 mL of brine was mixed with 99.5 mL of distilled water and 3–4 drops of potassium dichromate. Subsequently, silver nitrate was added until a noticeable colour change occurred.

Olive samples from each fermentation vessel were randomly taken by duplicate to analyze the firmness, surface colour, and moisture of fruit parameters at 0, 25, 68, and 106 days of fermentation following the methods described elsewhere (Bautista-Gallego et al., 2011; Chen et al., 2010). Day 0 refers to the fruit after the pre-processing step, which includes treatment with 1-MCCP, heat treatment, and processing style right before adding the brine. Briefly, the colour of ten table olives per duplicate was measured using a spectrophotometer Model CM-5 (Konica Minolta Sensing Americas, USA), following the manufacturer’s instructions. Interference by stray light was minimized by covering the samples with a box with a matt black interior. The colour was expressed as the CIE LAB parameters (L*, a*, b*), also used in the hue angle (h) calculus. The firmness of the olives was measured using a Kramer shear compression cell coupled to a Food Texture Analyzer FTM-50 (Techlabsystems, Spain). The crosshead speed was 200 mm/min. The firmness, expressed as kN/100 g flesh, was the mean of 10 replicate measurements performed on 3 pitted olives. Moisture content was determined in duplicate by drying 20 g of crushed olive flesh in an oven model Selecta DigiHeat (J.P. Selecta, Barcelona, Spain) at 102 °C until weight stabilization.

Individual reducing sugars (glucose, fructose, sucrose, and mannitol) were determined in an HPLC system at raw material and after each step of previous treatments and at 0, 25, and 106 days of fermentation, according to the methods developed by Sánchez et al. (2000). The system was composed of a pump model Jasco PU-2089, an autosampler module model AS-2055 (Jasco, Japan), a detector model Varian ProStar 350 RI, a thermostatted Column Compartment TCC-100 (which includes column and heater) (Dionex, USA), a hardware interface between the PC and the components system model LC Net II/ADC (Jasco, Japan), and the software ChromNav (Jasco, Japan) for analyzing the data.

Statistical Analysis

We initially conducted a preliminary analysis to explore the effect of treatments on the sugar content in fruits during the initial processing steps and the changes in the physicochemical characteristics of fruits and brine over time. Subsequently, the sugar content at the end of the processing steps and the physicochemical characteristics of fruits and brines at the end of the fermentation process were subjected to an analysis of variance using the ANOVA module of XLSTAT v 2017 (Addinsoft, XLSTAT Statistical and Data Analysis Solution. New York). For the ANOVA analysis, a0 = 0 was considered, and the stepwise option was employed to select variables significantly contributing to the models, as determined through the standardized coefficients. A p-value ≤ 0.05 was consistently applied as the cut-off.

Additionally, we examined the evolution of the physicochemical parameters of fruits and brines by calculating the area under their respective curves over time. These estimations were performed by integration using Origin Pro 7.5 (OriginLab, Northampton, US). A significant effect of a specific treatment would result in curves above those with lower or non-influential effects. The resulting multiple sets of data were analyzed using Partial Least Square Regression (PLS-R). Similar to ANOVA, the contributions of diverse variables were evaluated based on their standardized coefficients. In the multivariate analysis, the data were column-wise centred before the study. This step aimed to remove the potential impact of large differences between the absolute values of certain variables (such as texture vs pH). Centring the data facilitated a focus on the relative changes within each variable and helped mitigate the influence of the absolute values.

Results

Preliminary Analysis

This section includes information on a first general analysis of the evolution of the physicochemical characteristics of fruits and brines as a function of the type of treatment.

Fruits

Table 1 exhibits the changes in total sugar content during the first processing steps (before fermentation), representing the last column of the fruit concentrations at the moment of brining. A first overview indicates that 1-MCP had no effect; heat shock reduced sugars in only two fermenters, whereas lye treatment decreased them by approximately 40–50%. Therefore, irrespective of other treatments, the sugar at brining in Spanish was lower than in the natural method.

The initial texture of the fruits changed moderately during processing (Fig. 2A). After brining, olives following natural fermentation (containers 1, 5, 7, 8, and 8b) retained a markedly higher texture than Spanish style processing (containers 2,3, 3b, 4, and 6) due to the softening caused by the ley treatment. However, it is important to note that there were also differences within each group due to the effects of the other applied treatments.

Treatments also affected moisture content (Fig. 2B), particularly in containers following the Spanish style (2, 3, 3b, 4, and 6). Container 6, however, exhibited a sharp decrease towards the end of the process. Nonetheless, the differences between processing styles were less pronounced than in texture changes. Overall, the final moisture values ranged between 67 and 73%. Any increase or decrease from the initial level is important since such changes impact production costs.

Table S2 provides information on the changes in surface colour (L, a*, b*, and h) of the fruits from the diverse treatments over time. While changes in the raw material (fresh fruits) were relevant, assessing the effects of treatments solely by visual evolution becomes challenging. Overall, the processing of olives led to a slight decrease in luminosity (L). However, the impact was more pronounced in reducing b* and h or increasing a* colour parameters over time.

Brines

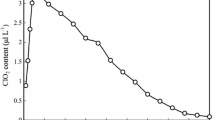

Regarding pH (Fig. 3A), the fermenters that underwent a lye treatment (2, 3, 3b, 4, and 6) initially had a higher pH level. However, the pH values decreased rapidly and became approximately similar to the remaining containers after 13 days of fermentation. The containers with natural olives (7, 8, and 8b) had the typical pH of just brined olives, showing a slight decrease. In contrast, container 7 experienced a more rapid decline, possibly due to the effect of the 1-MCP treatment or the lack of DMDC.

The evolution of titratable acidity exhibited noticeable differences among the containers (Fig. 3B). Containers 2, 6, and 7, which underwent heat shock treatment, displayed higher titratable acidity values over time. Conversely, containers 3b and 4, which followed the Spanish style without heat shock, acidified slowly and reached a lower final level of acidity. The remaining containers (natural processes) also showed some acid production levels but at a slower rate and to a lesser extent.

Concerning the combined acidity (Fig. 3B), the containers that followed the Spanish style exhibited higher levels of this parameter because of the lye treatment and more extensive lactic fermentation. On the contrary, olives following natural fermentation processes had lower values, except for container 7, which underwent a quasi-lactic fermentation likely due to the heat shock treatment.

Finally, the levels of NaCl were associated with the processing style, with containers 2, 3, 3b, 4, and 6 (Spanish style) showing higher levels than natural olives (Fig. 3D). However, as the content of this chemical was not particularly controlled in this experiment, its areas will not be analyzed in detail.

Statistical Analysis

Despite the described overall changes in the physicochemical parameters, evaluating the effects of the variables remains challenging and necessitates proper statistical analysis. In this section, we explore the impact of the four controlled variables in the experimental design on (i) changes in fruit sugars during the initial processing steps, (ii) the physicochemical parameters of fruits and brines at the end of the fermentation process, and (iii) the areas under the physicochemical parameters of fruits and the brines. For the first two statistical analyses, unidimensional ANOVA was employed, and their results are of primary interest to consumers. In the third case, multivariate analysis was conducted by PLS-R to evaluate the fermentative processes; the findings from this analysis would be valuable for processors.

Unidimensional ANOVA Study

This section focuses on the sugar content at the end of the pre-treatment steps and the final physicochemical characteristics of fruits and brines. Firstly, an overview of the variables and interactions specific to each treatment will be discussed. Subsequently, a summary of the effects of the variables included in the experimental design on the parameters mentioned above will be presented.

Fruits

Regarding the content of sugars left in the flesh after the pre-treatment steps, the selected variable was C (processing style) as well as the interactions A (application of 1-MCP)*B (heat shock), C*D (addition of DMDC), and A*B*C and explained 99.3% adjusted variance (Table 2). Other characteristics of the overall ANOVA model are recorded in Table S3. Their contributions, as assessed by their standardized coefficients and significance from the type III sum of squares, are illustrated in Fig. S1A (Supplementary Material) and Table S3. Most of the significant standardized coefficients were negative (Fig. S1A), indicating that Spanish-style processing leads to a decrease in the sugar content (Fig. S1B). However, the influence of adding DMDC, in this case, is scarce (Fig. S1C). Notably, the interaction treatment of 1-MCP with heat shock was somewhat negative, but their combination with the Spanish style resulted in a highly positive influence (Fig. S1A). Then, the application of 1-MCP, irrespective of other variables, appears to have diminished the available concentrations of sugars by slowing down their enzymatic liberation. Later, the heat shock also played a role, potentially contributing, at least partially, to the subsequent inactivation of such enzymes. Given the negative average effect, the impact could have been more pronounced in natural olives. Conversely, the liberation of sugars from glucosides by the effect of sodium hydroxide in Spanish-style processing overcomes this phenomenon.

Regarding the physicochemical parameters at the end of the fermentation process, the ANOVA model selected for moisture had three terms (C, A*B, A*B*C), which explained a substantial proportion of the variance (R2 adjusted, 0.898) (Table 2). Concerning the significance from the square sum type III ANOVA (Table S3, Supplementary Material), the interaction A*B was not significant but was retained because it participated in A*B*C. Since the significance of differences was not transitive, only the graph related to the effect of Spanish-style processing could be plotted (Fig. S2A, Supplementary Material). As suggested by the standardized coefficients, the major contributors were Spanish-style processing (C-ES) (Fig. S2B). The interaction (A-1MCP, application of 1-MCP)*(B-CC, heat shock) (Fig. S2A) enhanced the moisture content, but the three-way interaction (A-MCP)*(B-CC)* (C-ES, Spanish style) had a marked negative effect (Fig. S2A). Naturally processed olives (Nat) had much lower moisture than Spanish-style olives (ES).

Regarding texture, only the term C-ES (Spanish-style processing) was selected, although it was enough to explain a high proportion of the variance (91.3%). The sum of square type III was also significant (Table S3). The relevant impact of Spanish-style processing on texture is evident from its highly negative standardized coefficient (Fig. S3A, Supplementary Material) and the marked overall high texture observed in naturally processed olives regarding the Spanish-style olives (Fig. S3B).

Lumosity (L*) is an important factor for assessing the visual appearance of table olives. The model selected for this parameter included the interactions A*C and B*D, which explained 71.9% variance (Table 2). However, only B*D was significant according to the sum of square type III (Table S3), although the p-value was slightly above the thresholds. Besides, since the significance of differences was not transitive, their graphs could not be plotted. However, the standardized coefficients of the two interactions selected for the model were significant (their confidence intervals did not include zero). The first, (A-MCP, 1-MCP application) *(C*ES, Spanish style) was positive (improved L*) while (B-CC, application of heat shock)*(D-DMD, application of CMDC) was negative (reduced L*) (Fig. S4A, Supplementary Material).

The model for the colour a* parameter selected two terms (C and D), which explained 74.9% of the variance (Table 2). The p-values from the type III sum of squares in the ANOVA analysis confirmed that both were significant (Table S3). In addition, the standardized coefficients’ plot indicated that the C-ES (Spanish-style processing) contribution was markedly negative, while D-DMD (treatment with DMDC) was positive (Fig. S4B); however, from the olive product side, the interpretation should be reversed (favourable and unfavourable, respectively). The plot of the a* values versus C and D variables shows that the best levels (low a* values tend to have greenish tones) are due to the Spanish-style processing (Fig. S4C), while olives treated with DMDC have high a* values (worse colour) (Fig. S4D).

Finally, for the hue angle parameter (h), variable C and interactions A*B, B*D, and C*D were selected for the model, which explained 90.8% variance (adjusted R-square). However, according to the type III sum of squares analysis, only C and B*D interactions were recognized as significant (Table S3). As in previous parameters, the standardized coefficients did not fully agree with the model results. The coefficients (C-Es, Spanish style) and the interactions (A-1MCP, application of 1MCP)*(B-CC, heat sock), which played a favourable role, and (B-CC, heat shock)*(D-DMD, addition of DMDC to brine), which was negative (unfavourable), were significant (Fig. S5A, Supplementary Material). The LS means for the interactions could not be plotted for the same reasons mentioned above for some previous parameters. However, the effect of C on h was apparent since Spanish-style processing (ES) led to significantly higher h values than natural (Nat), indicating a major approximation to yellowish tones (Fig. S5B).

Brines

According to the ANOVA analysis, pH was one of the most affected parameters by the variables under study. There were selected 5 variables that accounted for the 99.9% adjusted variability (Table 2), and all of them were highly significant based on the sum square type III ANOVA (Table S3). Notice that low pH values are favourable for product preservation. Then, the negative values of the standardized coefficients for B-CC (heat shock), D-DMDC (addition of DMDC), and the interactions (A-1MCP, 1-MCP treatment)*(B-CC, heat shock) and (A-MDP,1-MCP treatment)*(D-DMDC, addition of DMDC) imply favourable contributions; on the contrary, the coefficient corresponding to (B-CC, heat shock)*(D-DMDC, addition of DMDC) may increase pH and played an unfavourable role (Fig. S6A, Supplementary Material). The graph comparing B levels is omitted because their effects can easily be deduced from B*A and B*D. The application of heat shock (CC) and 1-MCP (A-MCP) lowered the pH (Fig. S6B). On the contrary, the combination of the heat shock (CC) with DMDC (D-DMD) caused an increase in pH values (Fig. S6B, C, respectively). Overall, treatment without DMDC (D-SDMD) leads to lower pH levels than those receiving it. On the contrary, applying DMDC (D-DMD) increases the pH, regardless of whether it was combined with 1-MCP treatment or not, but only in the case of heat shock (B-CC) (Fig. S6D–F, respectively). Then, overall, the absence of DMDC in the initial brine always produced lower pH values (Fig. S6D).

Based on the stepwise option for variable selection, the ANOVA model for titratable acidity only considers a significant contribution from the interaction A*B (Table 2). This selection was confirmed by the sum of squares type III (Table S3). This significance is further supported by the standardized coefficient for the interaction (A-MCP, application of 1-MCP)*(B-CC, heat shock) as illustrated in Fig. S7A (Supplementary Material), implying that olives suffering heat shock, in conjunction with the application of 1-MCP (A-MCP), produce high titratable acidy values. However, it is worth noticing that although the model exhibits statistical significance, it only explains 45.9% of the adjusted variance (Table 2), implying that other uncontrolled variables also influence titratable acidity formation.

Finally, the combined acidity model resulting from the stepwise selection procedure only retained variable C, which explains 93.6% of the adjusted R-square (Table 2). The sum of squares type III (Table S3) and the standardized coefficients (Fig. S7B) confirmed the model. The plot of combined acidity according to C levels shows that the Spanish style (C-ES) contributed the highest overall values (Fig. S7C).

Quantification of the Effects and Interactions

The previous information has allowed obtaining detailed information on the impact and interactions of the variables and their levels. However, a summary of the overall (regardless of the others) and variable different levels combinations in actual values would also be valuable. Table 3 illustrates the values the models deduced by ANOVA predicted for the diverse physicochemical characteristics when they existed and were significant.

Regarding individual effects of variables, the A (1-MCP treatment) variable alone did not affect any of the studied parameters. Variable B was significant only for pH, and overall, the application of heat shock caused a significant decrease in pH (3.77) vs processes with olives without it (3.95) (Table 3). Variable C (processing style) caused significant changes in most parameters. For example, the values (Spanish style vs natural process) were: sugars, 27.89 vs 42.89 g/kg flesh; moisture, 71.26 vs 67.82 g/100 flesh; texture, 2.39 vs 4.96 kN/100 g pitted olives. Readers can complete the evaluation of the effect of variable C (Spanish style vs natural olives) with the remaining parameters (a*, h, or combined acidity) directly from Table 3. For variable D (DMDC application vs absence), the parameters significantly affected were a* (3.747 vs 2.583) and pH (3.906 vs 3.811).

With respect to two-way interactions, the combinations of variable A with all the others included in the design had significant effects (Table 3) for different physicochemical parameters. For example, 1-MCP application (MCP level) followed by heat shock (CC, a level of B) produced the highest titratable acidity vs any other combination (1.393 vs 0.8558 g lactic/100 mL brine). Besides, 1-MCP application (MCP level) followed by Spanish-style processing (ES, a level of C) led to the highest luminance values vs the rest of the combinations (60.65 vs 57.63). 1-MCP application (MCP level) in the absence of DMDC (SDMD) reached the lowest pH (3.744) among A*D combinations. Finally, B*D interaction caused significant changes in several studied parameters. For example, combining its heat shock level (CC) with the application of DMDC (DMD) significantly reduced the value of L (54.672). The complete set of two-way interactions can be consulted in Table 3.

Eight (23, three variables at two levels) three-way interactions (A*B*C) significantly influenced sugar contents after pre-treatment steps and final moisture, producing the diverse combinations marked changes (mainly in sugars) (see Table 3 for details).

Multivariate Study

As the evolution of the process was followed by sampling olives and brines at selected time intervals, comparing the effects of variables by considering the overall response could also be reliable (see Table 4 to see the area under each physicochemical parameter). This type of analysis, based on the area below the corresponding curves, is relatively common in similar circumstances. Therefore, in this study, the physicochemical characteristics under investigation were also treated as responses to the combined effects of variables using PLS-R. However, it should be noted that, in this case, the estimation of interactions was not feasible.

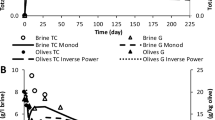

The PLS-R analysis found significant contributions of variables to the following parameters: moisture (C, processing style), texture (B, heat shock; C processing style), a* (B, heat shock; C processing style), h (B, heat shock; C processing style), titratable acidity (B, heat shock), and combined acidity (B, heat shock; C processing style) (Fig. 4).

As commented, the PLS-R analysis has some limitations regarding the roles of the explanatory variables in the responses. Nevertheless, the simultaneous projection on the t1 vs t2 dimensions provides an excellent visualization of their relationships (Fig. 5). The proximity of C-Nat to sugar content in the flesh and texture in the confidence circle (p = 0.05) indicates that natural processing leads to products with significant highest sugar content and texture. Besides, the proximity of containers 1 and 5 suggests that these treatments contained natural olives that offered the highest values of sugars and texture.

Similarly, high h* and L* values are related to using 1-MCP (A-MCP) but not DMDC (D-SDMD). Containers 3 and 3b had the highest values of these physicochemical characteristics. The use of DMDC (D-DMD) and the absence of 1-MCP (A-SMCP) is related to high a* values, characteristics associated with containers such as 8 and 8b. At the same time, high titratable acidity, combined acidity, and moisture characterize Spanish-style processing, possibly linked to the application of heat shock heat. These are good examples of these characteristics in containers 2 and 6. Interestingly, the effects of using 1-MCP or DMDC are inversely related, leading each combination to influence quite different characteristics. As observed, these variables are positively and negatively associated with the t1 axis, respectively. Finally, the absence of heat shock or its application positively and negatively correlates with the t2 axis. Besides, lack of heat shock could be related to higher texture, sugars, h* or L*. Conversely, its application (B-CC) increases titratable acidity and combined acidity in brine and even moisture in olives.

In summary, while the PLS-R analysis has limitations in fully capturing the roles of explanatory variables, the visual representation in the t1 vs t2 plot (Fig. 5) aids in understanding their relationships and the extent of their influence on the responses. Therefore, the unidimensional and multivariate are complementary. Positioning specific physicochemical characteristics close to the origin or within the inner circle in the correlation circle indicates a limited impact on them. In contrast, the situation inside the correlation circle means significant relationships.

Discussion

A previous study carried out by López-García et al. (2022) showed that treating green Manzanilla olives with 1-MCP before processing olives as Spanish style and natural led to lower pH levels, higher titratable acidity values, improved texture, better colour, and reached higher sensory scores than fruits following the traditional process. The implementation of further research on this subject was, then, exciting. This study investigates the combined effects of 1-MCP and other promising treatments (heat shock or use of DMDC for sanitizing initial brines) on the Spanish style and natural olive processing. This study aimed to assess their individual and combined effects (interactions) on the most common physicochemical characteristics of the produced olives and fermentation brines. It is important to note that, apart from the changes in NaCl content that are only dependent on intentional additions, the effects of several potential processing alternatives on sugars available for fermentation, moisture, texture, and colour of fruits over time and on pH, titratable acidity, and combined acidity in brines are challenging to evaluate without statistical analysis. Examining the effect of each variable in isolation would have required a large number of treatments. Conversely, combining treatments based on patterns derived from experimental design techniques can streamline the experiment. Besides, studying several variables simultaneously offers a more comprehensive and nuanced approach, allowing the exploration of interactions, the control of confounding variables, and providing a deeper explanation of complex phenomena.

In this survey, we used both final characteristics (as observed by consumers) and the overall evolution (as observed by processors) by assessing the responses by integrating the area over time below their respective curves, a method widely used in numerous fields (Scheff et al., 2011). Using this strategy, the unidimensional ANOVA (for the final point) could associate the four experimental variables (used at two levels) with the responses, except b*, by significant model and identify the levels (or their interactions) that contributed to the changes. This selection was possible thanks to the stepwise selection of terms in the ANOVA model, their confirmation by the p-values of their ANOVA, and the estimation of their corresponding standardized coefficients. The more relevant variable (participating in more models, alone or in combination) was C (processing style), which was selected from the models of sugars, moisture, texture, a*, h, and combined acidity (Tables 2 and S3). B (application or not of heat shock) was also included in six models: sugars, moisture, L, h, pH, and titratable acidity. D (addition or not of DMDC) only had an individual effect on a* but shared significant interactions regarding sugars, L, h, and pH. Finally, no individual impact was attributable to A (1-MCP), but its levels interacted with diverse levels of all the remaining variables in sugar contents, moisture, L*, h,* pH, and titratable acidity (Tables 2 and S3).

The terms of the diverse models are also illustrated by the levels or interactions resulting significantly (not including 0 in their confidence limits), as described in successive plots (Figs. S1–S7). They also show the effect of the various significant factors or interactions on the LS (least square) means of the diverse physicochemical variables. For example, there is a marked decrease of sugars at the initiation of the fermentation process in the Spanish style or the limited effect of adding or not adding DMDC to the initial brine, the higher moisture and lower texture of Spanish style vs natural olives. Our results can hardly be comparable to those observed by Ramin (2007), who reported that treating olives with 1-MCP 0.9–1.8 μL/L before storage significantly delayed olive softening because, in this case, the olives were stored in a cold room. Combining this treatment, at the highest concentration, with an immersion in calcium chloride had an even superior effect in preventing olive softening during similar cold storage (6 °C, 80% humidity), with fruits suffering minimal damage after 12 weeks (Amini & Ramin, 2015). Besides, the marked changes in texture caused by the lye treatment can also mask in some way the possibly lower changes due to 1-MCP or DMDC (mainly studied for controlling the fermentation course).

Three of the four studied variables changed olive colour because of the applied treatments. Notice the opposed trends observed for Spanish style (trend to greenish) or yellowish tones (Fig. S4B) and the more reddish olives when 1-MCP is applied (Fig. S5A). Notice that no variable influenced b*. These results are aligned with that found by Ramin (2007), who observed an increase in a* with temperature and no changes in the blue-yellow ordinates (b*). The treatment improved h* compared to the control and produced more attractive table olives. Interestingly, pH was one of the most influenced brine parameters (Fig. S6), with the application of DMDC leading to high pH values (as opposed to the expected effect) (Fig. S6D) or the systematic lower pH observed when 1-MCP is applied (Fig. S6B, E). Combined acidity was related to the lye treatment of the Spanish style (Fig. S7C). However, the changes in titratable acidity were unexpected since only the Spanish style used followed a lactic process (Garrido-Fernández et al., 1997), but the improvement of the lactic production by heat shock (Fig. S7A) in both styles made the segregation of processing styles based on titratable acidity undistinguishable. This finding aligns with those reported by Rodríguez-Gómez et al. (2017), who said that the heat treatment favoured the lactic acid fermentation, retention of the green appearance of the fruits, stability during packaging, and led to the highest scores in the sensory evaluation.

Similarly, Ghabbour et al. (2023) used 60, 70, and 80 °C three times for 5 min, followed by adding oleuropein lytic agents to control the process of unsalted olives. Treatments at the highest temperature had the best results regarding reducing bitterness and colour. On the other hand, applying DMDC in Chinese cabbage caused a decrease in total aerobic plate count, as well as in the counts of total yeasts and moulds. Interestingly, its application also inhibited the activity of polyphenol oxidase and peroxidase late during storage (Chen et al., 2013). Its use has even been proposed as an alternative to heat treatment since the DMDC is a powerful antimicrobial agent, approved for use as a microbial control agent in juice beverages by the FDA (Yu et al., 2014).

In addition, readers may find more detailed comparisons of the effects of levels within each variable, except for A (1-MCP), whose individual effect was insignificant, or the combination of them in Table 3. For the B variable, the overall pH value of olives subjected to heat sock was lower (3.77) than in its absence (3.95). C variable influenced, as expected, most of the physicochemical characteristics of fruits. Overall, Spanish style led to the lowest sugars at the fermentation initiation (27.89 g/kg flesh), higher moisture (71.26%), softer texture (2.39 kN/100 g olives), and better colour (referred to that expected for Spanish style) with the lowest a* (2.26) and highest h (86.63). However, it only affected combined acidity (due to the ley treatment). Unfortunately, the global effect of the D variable was negative since its application led to the poorest values of a* (3.75) and the highest pH (3.91). It will be tedious to provide a detailed description of two and three-way interactions, but it is interesting to emphasize that, although A (use or not of 1-MCP) was not significant overall, its combination with heat shock (B) produced olives with the more exciting aspect (highest h, 85.808), lowest pH (3.620), and most elevated titratable acidity (1.393 g lactic/100 mL brine). Other interesting contrasts can be consulted directly in Table 3. These trends made it challenging to continue the research regarding the potential application of such a compound in table olives since its application will not leave any residue in the final product (Watkins, 2006). The US Environmental Protection Agency has established an exemption from the requirements of a tolerance for residues of 1-MCP in or on fruits and vegetables when used as a post-harvest plant growth regulator (US EPA, 2006).

Finally, all these multiple and complex relationships were simplified in plotting correlations on the t1 × t2 plane (Fig. 5). The plot visualized all the previously commented influences of the explanatory and response variables and was very helpful in presenting all these relationships simultaneously. In this way, the links between natural processing, good texture, and higher sugar content in the presence of 1-MCP and the absence of DMDC coincided in containers 8 and 8b. On the contrary, the Spanish style is strongly linked to high moisture, high values of h, L*, and combined acidity or titratable acidity. Also, olives with high h and L* values are related to the treatment with 1-MCP and the absence of DMDC addition after brining. However, the a* colour parameter offers an opposite trend. A closed relationship with some parameter also means the absence/low values of those in the opposed position. Notice the opposed ubications of the two heat sock levels, which are significantly related to the t2 axis. Thus, the heat sock application could be associated with parameters with negative t2 axis, such as moisture, combined acidity, or titratable acidity values. On the contrary, the lack of a heat sock implies more sugars and higher texture with elevated h and L* values.

Conclusions

The analysis of the results showed that applying 1-MCP alone as a pre-treatment of olives did not significantly affect fermentation. Processing style was the most influential variable as it, regardless of any other, influenced most of the controlled parameters. Spanish style led to olives with the highest moisture, luminance, and combined acidity; on the contrary, natural olives retained more sugars, had higher texture, and were more greenish. Overall, adding DMDC to the initial brine caused some colour degradation but reduced pH. However, combining 1-MCP treatment with other factor levels significantly affected most parameters, except texture, a*, and combined acidity. Applying 1-MCP improved sugar content and luminance in olives and titratable acidity in brine when combined with heat shock.

Additionally, combining 1-MCP with the Spanish style improved luminance, and when applied together with DMDC, it led to the lowest pH in the two-way interactions. Concerning the interaction processing style*DMDC, natural olives consistently showed higher sugar content than the Spanish style, but combining this style with the addition of DMDC reached the lowest sugar level. Regarding the three-way interaction (treatment with1-MCP*heat shock*processing style), the use of 1-MCP with heat shock, sugars, and moisture mainly depended on the processing style, with the highest levels for sugars usually observed in natural olives and those of moisture in the Spanish style. These results demonstrated that the combined application of 1-MCP and heat shock, and in lower-intensity DMDC, may condition the Spanish style and natural table olive processing and modulate their physic-chemical characteristics. Further research on these effects at an industrial scale can help design new table olive processing techniques with more controllable product profiles.

Data Availability

No datasets were generated or analysed during the current study.

References

Amini, F., & Ramin, A. (2015). Effect of 1-methylcyclopropane in combination with calcium chloride on post-harvest storage and quality of green olives. Progress in Biological Sciences, 5(1), 121–131.

Balatsouras, G., Tsibri, A., Dalles, T., & Doutsias, G. (1983). Effects of fermentation and its control on the sensory characteristics of Conservolea variety green olives. Applied and Environmental Microbiology, 46(1), 68–74.

Bautista-Gallego, J., Arroyo-López, F. N., Romero-Gil, V., Rodríguez-Gómez, F., & Garrido-Fernández, A. (2011). Evaluating the effects of zinc chloride as a preservative in cracked table olive packing. Journal of Food Protection, 74(12), 2169–2176.

Burg, S. P., & Burg, E. A. (1962). Role of ethylene in fruit ripening. Plant Physiology, 37(2), 179.

Chen, Y., Wang, H., Xu, Y., Wu, J., & Xiao, G. (2013). Effect of treatment with dimethyl dicarbonate on microorganisms and quality of Chinese cabbage. Post-Harvest Biology and Technology, 76, 139–144.

Chen, Z., Zhu, C., Zhang, Y., Niu, D., & Du, J. (2010). Effects of aqueous chlorine dioxide treatment on enzymatic browning and shelf-life of fresh-cut asparagus lettuce (Lactuca sativa L.). Post-harvest Biology and Technology, 58(3), 232–238.

Chhetri, R. T., Magar, P., Kandel, S., & Gnyawali, P. (2022). A review paper on post-harvest loss on fruits and vegetables. Food and Agri Economics Review (FAER), 3(1), 01–04. https://doi.org/10.26480/faer.01.2023.01.04

Costa, A., Barata, A., Malfeito-Ferreira, M., & Loureiro, V. (2008). Evaluation of the inhibitory effect of dimethyl dicarbonate (DMDC) against wine microorganisms. Food Microbiology, 25(2), 422–427.

Daly, J., & Kourelis, B. (2001). Synthesis methods, complexes and delivery methods for the safe and convenient storage, transport and application of compounds for inhibiting the ethylene response in plants. U.S. Patent 6313068.

EFSA Panel On Food Additives and Nutrient Sources Added to Foods, ANS. (2015). Scientific opinion on the re-evaluation of dimethyl decarbonate (DMDC, E 242) as a Food Additive. EFSA Journal, 13(12), 4319.

Etchells, J. L., Borg, A. F., Kittel, I. D., Bell, T. A., & Fleming, H. P. (1966). Pure culture fermentation of green olives. Applied Microbiology, 14(6), 1027–1041.

Fang, Y., & Wakisaka, M. (2021). A review on the modified atmosphere preservation of fruits and vegetables with cutting-edge technologies. Agriculture, 11(10), 992.

Garrido-Fernández, A., Fernández-Díez, M. J., & Adams, R. (1997). Table olives: Production and processing. Chapman & Hall.

Ghabbour, N., Rokni, Y., Abouloifa, H., Bellaouchi, R., Hasnaoui, I., Gaamouche, S., ... & Asehraou, A. (2023). Controlled fermentation of heat-shocked, unsalted and inoculated Moroccan Picholine green olives. Grasas y Aceites, 74(1), e485–e485.

Lata, D., & Sujayasree, O. I. (2021). ignificance of ethylene in post-harvest technology. In S. Mitra (Ed.), Post-harvest management and horticultural crops, chapter 15 (pp. 250–262). New Delhi (India): Publishing House.

Li, L., Lichter, A., Chalupowicz, D., Gamrasni, D., Goldberg, T., Nerya, O., & ... Porat, R. (2016). Effects of the ethylene-action inhibitor 1-methylcyclopropene on post-harvest quality of non-climacteric fruit crops. Post-harvest Biology and Technology, 111, 322–329.

López-García, E., Benítez-Cabello, A., Rodríguez-Gómez, F., Martín-Arranz, V., Garrido-Fernández, A., & Arroyo-López, F. N. (2022). Influence of 1-methylcyclopropene (1-MCP) on the processing and microbial communities of Spanish-style and directly brined green table olive fermentations. Fermentation, 8(9), 441.

Ministerio de Agricultura Pesca y Alimentación, Secretaría General de Agricultura y Alimentación. (2007). Resolución de la Dirección General de Sanidad de la Producción Agraria. Authorization number 23919. Madrid, Spain. https://www.mapa.gob.es/es/agricultura/temas/sanidad-vegetal/listasustanciasactivasaceptadasexcluidas_tcm30-618972.pdf

Ramin, A. A. (2007). Effects of storage temperatures and 1-MCP treatment on post-harvest quality of green olives. Fruits, 62(6), 383–390.

Ramírez, E., Brenes, M., de Castro, A., Romero, C., & Medina, E. (2017). Oleuropein hydrolysis by lactic acid bacteria in natural green olives. LWT - Food Science and Technology, 78, 165–171.

Rodríguez-Gómez, F., Ruiz-Bellido, M. Á., Romero-Gil, V., Benítez-Cabello, A., Garrido-Fernández, A., & Arroyo-López, F. N. (2017). Microbiological and physicochemical changes in natural green heat-shocked Aloreña de Málaga table olives. Frontiers in Microbiology, 8, 2209.

Sánchez, A. H., De Castro, A., Rejano, L., & Montaño, A. (2000). Comparative study on chemical changes in olive juice and brine during green olive fermentation. Journal of Agricultural and Food Chemistry, 48(12), 5975–5980.

Satekge, T. K., & Magwaza, L. S. (2022). Post-harvest application of 1-methylcyclopropene (1-MCP) on climacteric fruits: Factors affecting efficacy. International Journal of Fruit Science, 22(1), 595–607.

Scheff, J. D., Almon, R. R., DuBois, D. C., Jusko, W. J., & Androulakis, I. P. (2011). Assessment of pharmacologic area under the curve when baselines are variable. Pharmaceutical Research, 28, 1081–1089.

Sisler, E. C., & Blankenship, S. M. (1996). Method of counteracting an ethylene response in plants. U.S. Patent 5518988.

US EPA (US Environmental Protection Agency). (2006). 1-Methylcyclopropene (MCP) (224459). Fact sheet.

Vilhena, N. Q., Cervera-Chiner, L., Moreno, A., & Salvador, A. (2023). Recent development in the preharvest 1-MCP application to improve post-harvest fruit quality.

Watkins, C. B. (2006). The use of 1-methylcyclopropene (1-MCP) on fruits and vegetables. Biotechnology Advances, 24(4), 389–409.

Yu, Y., Xiao, G., Xu, Y., Wu, J., & Wen, J. (2014). Effects of dimethyl dicarbonate (DMDC) on the fermentation of litchi juice by Lactobacillus casei as an alternative of heat treatment. Journal of Food Science, 79(5), M947–M954.

Zhang, J., Yu, X., Sun, Y., Guan, X., Qin, W., Zhang, X., ... & Zhou, J. (2022). Effects of dimethyl dicarbonate on improving the aroma of melon spirits by inhibiting spoilage microorganisms. Journal of Food Processing and Preservation, 46(6), e16499.

Acknowledgements

AGF thanks the CSIC for his “Ad honorem” appointment. We also thank Dr Eve Dupille, R&D Manager of Agrofresh, for providing the 1-MCP compound for the experiments, and Juan Carlos Roldán and Rosa Torres from Jolca S.A. for providing the fruits.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. MCIU/AEI/FEDER, UE, grant number TOBE project (RTI-2018-100883-B-I00) funded this research.

Author information

Authors and Affiliations

Contributions

Conceptualization: Antonio Garrido-Fernández; methodology: Elio López-García, Francisco Rodríguez-Gómez, Virginia Martín-Arranz, Antonio Benítez-Cabello, Verónica Romero-Gil; analysis and data curation: Antonio Garrido-Fernández, Francisco Noé Arroyo-López, Elio López-García, Antonio Benítez-Cabello; writing and review: Francisco Noé Arroyo-López, Antonio Benítez-Cabello, Elio López-García, Antonio Garrido-Fernández; funding: Francisco Noé Arroyo-López. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

López-García, E., Benítez-Cabello, A., Rodríguez-Gómez, F. et al. Impact of 1-Methylcyclopropene in Combination with Heat Shock and Dimethyl Dicarbonate on the Physicochemical Profiles of Table Olive Fermentations. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03339-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03339-7