Abstract

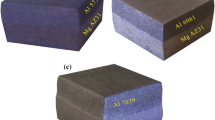

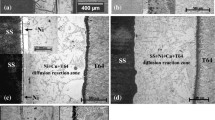

Additive manufacturing is gaining wide acceptance in the manufacturing industries, but the joining of additively manufactured components is a rarely researched area. In this study, diffusion bonding of directed energy-deposited (DED) Mg alloy (AZ31), using an electric arc as an energy source was analyzed. Diffusion bonding (DB) was performed in a non-vacuum condition with gallium treatment at the faying surfaces to eliminate the oxide formation and promote metallurgical contact. Microstructural and elemental distribution analyses of additively manufactured AZ31 alloy and diffusion-bonded joints were carried out using FESEM and EPMA. EBSD analysis indicated that the bonding interface is characterized by discontinuous dynamic recrystallized grains featured by grain boundary bulging and grain boundary migration. The 90° triple junction observed at the interface migrates to reduce the grain boundary energy. The fine precipitates of β-Mg17Al12 were distributed uniformly throughout the material, which enhanced precipitation hardening. High integrity joints without any voids could be obtained by diffusion bonding and the joint line was not discernible. The high-intensity elemental content at the joint interface highlights the enhanced interdiffusion of constituent atoms across the faying surfaces.

Similar content being viewed by others

References

ASTM 52900, ASTM Int. 2021, 1 (2021).

E. Aldalur, A. Suárez, and F. Veiga, J. Mater. Process. Technol. 297, (2021).

Y. Guo, G. Quan, Y. Jiang, L. Ren, L. Fan, and H. Pan, J. Magnes. Alloy. 9, 192 (2021).

X. Duan, Q. Li, W. Xie, and X. Yang, J. Mater. Process. Technol. 311, (2023).

P. Wang, H. Zhang, H. Zhu, Q. Li, and M. Feng, J. Mater. Process. Technol. 288, 116895 (2021).

K. G. Prashanth, R. Damodaram, S. Scudino, Z. Wang, K. Prasad Rao, and J. Eckert, Mater. Des. 57, 632 (2014).

K.G. Prashanth, R. Damodaram, T. Maity, P. Wang, and J. Eckert, Mater. Sci. Eng. A 704, 66 (2017).

J. Wang, Y. Wang, and J. Shi, Int. J. Adv. Manuf. Technol. 115, 1037 (2021).

R. Dipin Kumar, Y. Koli, and S. Aravindan, Mater. Lett. 337, 133976 (2023).

W. Zhong and J.C. Zhao, Acta Mater. 201, 191 (2020).

M. Li, L. Lu, Y. Fan, M. Ma, T. Zhou, F. Qi, H. Zhang, and Z. Wu, Mater. Today Commun. 34, 105467 (2023).

B. Mordike and T. Ebert, Mater. Sci. Eng. A 302, 37 (2001).

H. Takagi, H. Sasahara, T. Abe, H. Sannomiya, S. Nishiyama, S. Ohta, and K. Nakamura, Addit. Manuf. 24, 498 (2018).

K. V, N. Kumar B, S. Kumar S, and V. M, Addit. Manuf. 55, 102802 (2022).

J. Wang, Z. Zhao, P. Bai, R. Zhang, Z. Zhang, L. Wang, W. Du, F. Wang, and Z. Huang, J. Alloys Compd. 939, 168665 (2023).

X. Yang, J. Liu, Z. Wang, X. Lin, F. Liu, W. Huang, and E. Liang, Mater. Sci. Eng. A 774, 138942 (2020).

X. Fang, J. Yang, S. Wang, C. Wang, K. Huang, H. Li, and B. Lu, J. Mater. Process. Technol. 300, 117430 (2022).

Y. Koli, N. Yuvaraj, A. Sivanandam, and Vipin, Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 236, 984 (2022).

C. Zhang, H. Li, and M. Li, JOM 71, 1175 (2019).

L. Han, J. Wang, Y. Chen, Z. Liu, Y. Huang, D. Liu, L. Luo, C. Liu, Y. Liu, and Z. Wang, J. Mater. Process. Technol. 302, 117508 (2022).

Z. Yang, X. Zhang, J. Cheng, X. Li, and Y. Shen, Mater. Today Commun. 35, 105642 (2023).

H. Somekawa, H. Watanabe, T. Mukai, and K. Higashi, Scr. Mater. 48, 1249 (2003).

O. Torun, A. Karabulut, B. Baksan, and I. Çelikyürek, Mater. Des. 29, 2043 (2008).

X. Tong, L. Zai, G. You, H. Wu, H. Wen, and S. Long, Mater. Sci. Eng. A 767, 138408 (2019).

M. Joseph Fernandus, T. Senthilkumar, V. Balasubramanian, and S. Rajakumar, Mater. Des. 33, 31 (2012).

M. Jafarian, A. Khodabandeh, and S. Manafi, Mater. Des. 65, 160 (2015).

T. Yang, S. Geng, D. Zhang, K. Wang, C. Guo, and Y. Zhang, Weld. World 541 (2023).

H. Shakeri and M.A. Mofid, Met. Mater. Int. 27, 4132 (2021).

N. Nadermanesh, A. Azizi, and S. Manafi, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 235, 2118 (2021).

T. Klein, A. Arnoldt, M. Schnall, and S. Gneiger, JOM 73, 1126 (2021).

X. Niu, G. Li, Z. Zhang, P. Zhou, H. Wang, S. Zhang, and W. Cheng, Mater. Sci. Eng. A 743, 207 (2019).

J.Y. Zhang, M.Y. Sun, B. Xu, X. Hu, S. Liu, B.J. Xie, and D.Z. Li, Mater. Sci. Eng. A 746, 1 (2019).

Y. Sun, X. Liu, W. Wang, Y. Yang, and W. Zhang, J. Alloys Compd. 957, 170390 (2023).

L. Zhang, Z. Zhang, L. Huang, L. Wu, Y. Sun, and S. Guan, JOM 75, 2374 (2023).

H. Zhang, S. Hu, Z. Wang, and Y. Liang, Mater. Des. 86, 894 (2015).

A. R. Begg, EP 0123382 A1 (1984).

A.A. Shirzadi, G. Saindrenan, and E.R. Wallach, Mater. Sci. Forum 396–402, 1579 (2002).

A.A. Shirzadi, A. Laik, R. Tewari, J. Orsborn, and G.K. Dey, Materialia 4, 115 (2018).

H. Shi, Y. Huang, Q. Luo, S. Gavras, R. Willumeit-Römer, and N. Hort, J. Magnes. Alloy. 10, 3289 (2022).

Z. Zhou, Y. Cui, Q. Wu, G. Xu, L. Zhou, and Y. Cui, Calphad Comput. Coupling Phase Diagrams Thermochem. 78, (2022).

A.A. Nayeb-Hashemi and J.B. Clark, Bull. Alloy Phase Diagrams 6, 434 (1985).

S.W. Lee, S.-H. Kim, and S.H. Park, J. Magnes. Alloy. 8, 537 (2020).

Acknowledgement

The authors acknowledge the central research facility at IIT Delhi for use of the FESEM TESCAN and EPMA facilities and Prof. Suresh Neelakantan, Department of Materials Science and Engineering, IIT Delhi for providing EBSD facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, R.D., Koli, Y. & Aravindan, S. Microstructural Analysis of Diffusion-Bonded AZ31 Mg Alloy Fabricated by Wire-Arc-Directed Energy Deposition for Lightweight Complex Structures. JOM (2024). https://doi.org/10.1007/s11837-024-06582-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06582-7