Abstract

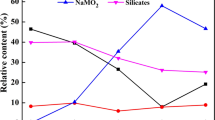

The effect of TiO2 on the phase transformation and microstructure evolution of Ti-containing melting slag in the alkali fusion process has been investigated. The results showed that, after alkali fusion roasting, the original phase of Ti-containing melting slag was completely decomposed by molten NaOH, and that the alkali fusion slag mainly included Na2TiO3 and NaMO2 (M = Ti, Mg). With increasing TiO2 content, NaMO2 and Na2TiO3 converted to each other, and the content of sodium magnesium silicate also changed with the “in and out” of Mg. The contents of NaAlO2 and silicates were not significantly affected by the TiO2 content, while the microstructure of the melting slag corroded by molten NaOH changed greatly. With increasing TiO2 content, the microstructure of the alkali fusion slag transformed from an uneven grain size to a uniform grain size, and ultimately a compact structure.

Similar content being viewed by others

References

H.L. Fan, D.F. Chen, P. Liu, H.M. Duan, Y.W. Huang, M.J. Long, and T. Liu, J. Non Cryst. Solids 493, 57 (2018).

L.Q. Dong, K. Cheng, W.J. Weng, C.L. Song, P.Y. Du, G. Shen, and G.R. Han, Thin Solid Films 519, 4634 (2011).

Y.H. Liu, F.C. Meng, F.Q. Fang, W.J. Wang, and J.L. Chu, Dyes Pigment. 125, 384 (2016).

J.B. Rosenbaum, JOM 34, 76 (1982).

W.Z. Liu, L. Lü, H.R. Yue, B. Liang, and C. Li, J. Alloys Compd. 705, 572 (2017).

F.L. Yang and V. Hlavacek, AICHE J. 46, 355 (2000).

J.P. Jalava, Ind. Eng. Chem. Res. 31, 608 (1992).

J.H. Braun, A. Baidins, and R.E. Marganski, Prog. Org. Coat. 20, 105 (1992).

W. Zhang, Z.W. Zhu, and C.Y. Cheng, Hydrometallurgy 108, 177 (2011).

A.L. Dann, R.S. Cooper, and J.P. Bowman, Water Res. 43, 2302 (2009).

B. Liang, C. Li, C.G. Zhang, and Y.K. Zhang, Hydrometallurgy 76, 173 (2005).

M.H.H. Mahmoud, Sep. Purif. Technol. 84, 63 (2012).

A.A. Nayl, I.M. Ismail, and H.F. Aly, Hydrometallurgy 98, 196 (2009).

C. Xu, Z. Yuan, and X. Wang, Chin. J. Chem. Eng. 14, 281 (2006).

H.G. Du, Theory of Smelting Vanadium-Bearing Titanomagnetite by Blast Furnace (Science Press, Beijing, 1996).

X.W. Lv, Z.G. Lun, J.Q. Yin, and C.G. Bai, ISIJ Int. 53, 1115 (2013).

D.S. Chen, B. Song, L.N. Wang, T. Qi, Y. Wang, and W.J. Wang, Miner. Eng. 24, 864 (2011).

Y.B. Wang, T. Qi, J.L. Chu, and W. Zhao, Rare Met. 29, 162 (2010).

L. Zhang, L.N. Zhang, M.Y. Wang, G.Q. Li, and Z.T. Sui, Miner. Eng. 20, 684 (2007).

W. Li, G.Q. Fu, M.S. Chu, and M.Y. Zhu, Steel Res. Int. 88, 1600120 (2017).

Z.F. Yuan, Y.F. Pan, E. Zhou, X.U. Cong, and S.Q. Li, J. Iron. Steel Res. Int. 14, 1 (2007).

W. Li, G.Q. Fu, M.S. Chu, and M.Y. Zhu, Ironmak. Steelmak. 44, 294 (2017).

Y.J. Zhang, T. Qi, and Y. Zhang, Hydrometallurgy 96, 52 (2009).

T.Y. Xue, L.N. Wang, T. Qi, J.L. Chu, J.K. Qu, and C.H. Liu, Hydrometallurgy 95, 22 (2009).

Y. Li, H.Y. Yu, Z.T. Zhang, M. Zhang, and M. Guo, ISIJ Int. 55, 134 (2015).

Y. Wang, J. Li, L. Wang, T.Y. Xue, and T. Qi, Ind. Eng. Chem. Res. 49, 7693 (2010).

D.S. Chen, L.S. Zhao, Y.H. Liu, T. Qi, J.C. Wang, and L.N. Wang, J. Hazard. Mater. 245, 588 (2013).

Y. Feng, J.G. Wang, L.N. Wang, T. Qi, T.Y. Xue, and J.L. Chu, Rare Met. 28, 564 (2009).

Y.F. Han, T.C. Sun, J. Li, T. Qi, L.N. Wang, and J.K. Qu, Int. J. Min. Met. Mater. 19, 205 (2012).

J. Ma, G.Q. Fu, W. Li, and M.Y. Zhu, Int. J. Min. Met. Mater. 27, 310 (2020).

W. Antony Hill and A.R. Moon, J. Am. Ceram. Soc. 68, C-266 (1985).

C.E. Bamberger and G.M. Begun, J. Am. Ceram. Soc. 70, C-48 (1987).

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (51904066), the Natural Science Foundation of Liaoning Province (2023-MS-075), and the Fundamental Research Funds for the Central Universities (N2325015).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, J., Li, W., Fu, G. et al. Effect of TiO2 on the Phase Transformation and Microstructure Evolution of Ti-Containing Melting Slag in the Alkali Fusion Process. JOM (2024). https://doi.org/10.1007/s11837-024-06558-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06558-7