Abstract

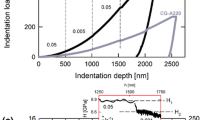

Berkovich nanoindentation was used to characterize viscoelastic and viscoplastic deformations in the semicrystalline polymers, poly(ether ether ketone) (PEEK) and low density polyethylene (LDPE). The quasistatic experiments generated viscoelastic moduli over four decades in frequency and hardness over more than four decades of indentation strain rate. These semicrystalline polymer results augment analogous results previously obtained from the amorphous polymers, poly(methyl methacrylate), polycarbonate, and polystyrene. Although nanoindentation viscoelastic moduli were all systematically higher than those from conventional measurements, viscoelastic moduli from nanoindentation and conventional measurements followed the same trends with frequency, which indicated that both types of measurements are sensitive to the same microphysical processes giving rise to the viscoelasticity. Differences in the path dependence of hardness were observed between polymers and attributed to differences in polymer glass transition temperatures. Flow stress versus strain rate data were also calculated from hardness versus indentation strain rate data and compared to literature values. Flow stress versus strain rate obtained from both nanoindentation and conventional uniaxial experiments agreed very closely. Collectively, the comparisons between nanoindentation and conventional measurements over wide timescales further confirmed that viscoelastic and viscoplastic deformations characterized by Berkovich nanoindentation can be related back to conventional measurements and have similar mechanistic interpretations.

Similar content being viewed by others

References

A.C. Fischer-Cripps, Nanoindentation, 2nd edn. (Springer, New York, 2004).

W.C. Oliver and G.M. Pharr, J. Mater. Res. 7, 1564 (1992).

N. Fujisawa and M.V. Swain, J. Mater. Res. 23, 637 (2008).

B. Tang and A.H.W. Ngan, J. Mater. Res. 18, 1141 (2003).

T. Jin, X. Niu, G. Xiao, Z. Wang, Z. Zhou, G. Yuan, and X. Shu, Polym. Test. 41, 1 (2015).

C.C. White, M.R. Vanlandingham, P.L. Drzal, N.K. Chang, and S.H. Chang, J. Polym. Sci. Part B (Polym. Phys.) 43, 1812 (2005).

R.S. Lakes, Viscoelastic Materials (Cambridge University Press, New York, 2009).

Y.-T. Cheng and C.-M. Cheng, J. Mater. Res. 20, 1046 (2005).

J.E. Jakes, R.S. Lakes, and D.S. Stone, J. Mater. Res. 27, 463 (2012).

J.E. Jakes, R.S. Lakes, and D.S. Stone, J. Mater. Res. 27, 475 (2012).

A. Strojny, X. Xia, A. Tsou, and W.W. Gerberich, J. Adhes. Sci. Technol. 12, 1299 (1998).

W. M. Mook and W. W. Gerberich, in Fundamenatal Nanoindentation Nanotribology IV, 2007, edited by E. Le Bourhis, D. J. Morris, M. L. Oyen, R. Schwaiger, and T. Straedler (Materials Research Society Symposium Proceedings, Warrendale, 2008), pp. 21–26.

B. Wolf and M. Goken, Zeitschrift Fur Met. 96, 1247 (2005).

M. Hardiman, T.J. Vaughan, and C.T. McCarthy, Polym. Test. 52, 157 (2016).

D. Tabor, Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 192, 247 (1948).

D. Tabor, Rev. Phys. Technol. 1, 145 (1970).

D.M. Marsh, Proc. R. Soc. Lond. A Math. Phys. Sci. 279, 420 (1964).

K.L. Johnson, J. Mech. Phys. Solids 18, 115 (1970).

K.L. Johnson, Contact Mechanics (Cambridge University Press, Cambridge, 1985).

Z.H. Melgarejo-Pinto, Plastic Deformation in Zirconium Based Metallic Glasses via Nanoindentation (The University of Wisconsin-Madison, 2016).

D.S. Stone and K.B. Yoder, J. Mater. Res. 9, 2524 (1994).

A.A. Elmustafa and D.S. Stone, Mater. Lett. 57, 1072 (2003).

G. Swallowe and S. Lee, J. Mater. Sci. 41, 6280 (2006).

J. Richeton, S. Ahzi, K.S. Vecchio, F.C. Jiang, and R.R. Adharapurapu, Int. J. Solids Struct. 43, 2318 (2006).

O.A. Hasan, M.C. Boyce, X.S. Li, and S. Berko, J. Polym. Sci. Part B Polym. Phys. 31, 185 (1993).

D.H. Ender, J. Appl. Phys. 39, 4877 (2003).

C.M.R. Dunn and S. Turner, Polymer (Guildf). 15, 451 (1974).

Y.Y. Wang, H. Nakanishi, Y.C. Jean, and T.C. Sandreczki, J. Polym. Sci. Part B Polym. Phys. 28, 1431 (1990).

P.J. Rae, E.N. Brown, and E.B. Orler, Polymer (Guildf). 48, 598 (2007).

J. Capodagli and R. Lakes, Rheol. Acta 47, 777 (2008).

M.F. Tambwe, D.S. Stone, A.J. Griffin, H. Kung, Y. Cheng Lu, and M. Nastasi, J. Mater. Res. 14, 407 (1999).

A.A. Elmustafa and D.S. Stone, J. Mech. Phys. Solids 51, 357 (2003).

J.E. Jakes, C.R. Frihart, J.F. Beecher, R.J. Moon, and D.S. Stone, J. Mater. Res. 23, 1113 (2008).

A.A. Ogale and R.L. McCullough, Compos. Sci. Technol. 30, 185 (1987).

M. Sumita, T. Ookuma, K. Miyasaka, and K. Ishikawa, J. Appl. Polym. Sci. 27, 3059 (1982).

D.S. Stone, K.B. Yoder, and W.D. Sproul, J. Vac. Sci. Technol. A Vac. Surf. Film. 9, 2543 (1991).

J.E. Jakes, J. Mater. Sci. 53, 4814 (2018).

D.S. Stone, J.E. Jakes, and A.A. Elmustafa, JOM (2024). https://doi.org/10.1007/s11837-024-06556-9.

J. Schindelin, I. Arganda-Carreras, E. Frise, V. Kaynig, M. Longair, T. Pietzsch, S. Preibisch, C. Rueden, S. Saalfeld, B. Schmid, J.-Y. Tinevez, D.J. White, V. Hartenstein, K. Eliceiri, P. Tomancak, and A. Cardona, Nat. Methods 9, 676 (2012).

J.H. Strader, S. Shim, H. Bei, W.C. Oliver, and G.M. Pharr, Philos. Mag. 86, 5285 (2006).

B.J. Briscoe, L. Fiori, and E. Pelillo, J. Phys. D Appl. Phys. 31, 2395 (1998).

G. Feng and A.H.W. Ngan, J. Mater. Res. 17, 660 (2002).

C.A. Tweedie and K.J. Van Vliet, J. Mater. Res. 21, 3029 (2006).

J.E. Jakes and D. Stauffer, J. Mater. Res. 36, 2189 (2021).

P. Nikaeen, D. Depan, and A. Khattab, Nanomaterials 9, 1357 (2019).

G. Odegard, T. Gates, and H. Herring, Exp. Mech. 45, 130 (2005).

G.Z. Voyiadjis, A. Samadi-Dooki, and L. Malekmotiei, Polym. Test. 61, 57 (2017).

N. Bouaita, S.J. Bull, J.F. Palacio, and J.R. White, Polym. Eng. Sci. 46, 1160 (2006).

S.L. Rosen, Fundamental Principles of Polymeric Materials, 2nd edn. (Wiley, New York, 1993).

T. Chudoba and N.M. Jennett, J. Phys. D Appl. Phys. 41, 215407 (2008).

S. Fulco, S. Wolf, J.E. Jakes, Z. Fakhraai, and K.T. Turner, J. Mater. Res. 36, 2176 (2021).

J.L. Jordan, D.T. Casem, J.M. Bradley, A.K. Dwivedi, E.N. Brown, and C.W. Jordan, J. Dyn. Behav. Mater. 2, 411 (2016).

M.F. Omar, H.M. Akil, and Z.A. Ahmad, Mater. Sci. Eng. A 538, 125 (2012).

M. Xu, G. Huang, S. Feng, G.J. McShane, and W.J. Stronge, Polymers (Basel) 8, 77 (2016).

A.A. Elmustafa, S. Kose, and D.S. Stone, J. Mater. Res. 22, 926 (2007).

G. Kermouche, J.L. Loubet, and J.M. Bergheau, Mech. Mater. 40, 271 (2008).

Acknowledgements

This research was supported in part by the U.S. Department of Agriculture, Forest Service. We acknowledge the machine shop at the Forest Products Laboratory for machining the PEEK specimens. We also acknowledge Ken Smith from the Forest Products Laboratory for helping to perform PEEK DMA experiments. DSS acknowledges funding by the United States National Science Foundation Directorate for Engineering (CMMI-1232731), United States Forest Service (18-JV-11111129-036), and Wisconsin Alumni Research Foundation (MSN215857).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jakes, J.E., O’dell, J. & Stone, D.S. Viscoelastic Moduli and Path-Dependent Hardness Across Four Decades of Timescale in Semicrystalline Polymers from Berkovich Nanoindentation. JOM 76, 2956–2969 (2024). https://doi.org/10.1007/s11837-024-06551-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-024-06551-0