Abstract

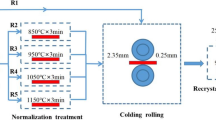

Effects of Sn on microstructure, texture and magnetic properties of 2.7%Si-0.5%Al non-oriented silicon steel in industrial production were studied by X-ray diffraction and electron backscattering diffraction. Furthermore, combining first-principles simulation with White–Coghlan model calculation, grain boundary segregation of Sn was also investigated. In Sn-0.05 steel, cold-rolled sheet showed more ingrain shear bands and intensity of textures weakened significantly. Addition of Sn obviously reduced intensity of {111}<112> and increased intensity of {114}<481>; strong {100}<120> and nearly Goss textures appeared in annealed sheet. P1.5/50 decreased by 0.05W/kg, B50 increased by 0.005 T, and stability of magnetic properties were obviously improved of Sn-0.05. In the unit grain boundary layer (1 Å−2), the excess solute concentration on the grain boundary layer of Sn corresponding to 20,000–30,000 appm was 0.16–0.22 and gradually decreased with temperature and increased with intragranular solute content. As a segregation element, during annealing process of hot-rolled band and cold-rolled sheet, Sn exerted a drag force on the grain boundaries, thus inhibiting the grain growth. {114}<481> and {100}<120> oriented grains could grow selectively and distribute evenly by virtue of their mobility and quantity advantage higher than {111}<112>, thus improving magnetic properties and stability of 2.7%Si-0.5%Al non-oriented silicon steel.

Similar content being viewed by others

References

He. Zhongzhi, Yu. Zhao, and L. Haiwen, Electrical Steel (Metallurgical Industry Press, Beijing, 2012).

Z. Zhenggui, and W. Dapeng, Texture and Magnetism of Non-oriented Silicon Steel (Metallurgical Industry Press, Beijing, 2012).

W. Mao, and P. Yang, Materials Science Principles on Electrical Steels (Higher Education Press, Beijing, 2013).

C. Lingfeng, and Z. Zhiyi, Electr. Eng. Mater. 3, 41–47 (2013).

L. Xiandong, W. Bo, Z. Jianru, et al., Electr. Eng. Mater. 5, 41 (2014).

Li. Zhichao, S. Qiang, Mi. Zhenli, et al., Trans. Mater. Heat Treat. 37(1), 90 (2016).

S. Qiang, Li. Zhichao, Mi. Zhenli, et al., Trans. Mater. Heat Treat. 37(4), 82 (2016).

Z. Pan, L. Yuan, X. Gu, et al., Improving the Properties of 50WG470 High Magnetic Induction Electrical Steel by Elevating Si Content and Reducing Mn Content. Iron Steel Vanadium Titanium 40(2), 166–170 (2019).

Du. Guangliang, F. Dajun, S. Wenmin, et al., Res. Iron Steel 44(1), 35 (2016).

H. Dong, Yu. Zhao, Yu. Xiao-Jun, et al., J. Iron Steel Res. (Int.) 16(6), 86 (2009).

G. Lyudkovsky, and P.K. Rastogi, Metall. Mater. Trans. A 15(2), 257 (1984).

M. Godec, M. Jenko, H.J. Grabke, et al., ISIJ Int. 39(7), 742 (2007).

K.S. Chang, ISIJ Int. 47(3), 466 (2007).

Li. Dechao, D. Junhui, C. Haipeng, et al., Heat Treat. Met. 043(011), 1 (2018).

N. Li, L. Xiang, and P. Zhao, Adv. Mater. Res. 602–604, 435 (2013).

R. Suehiro, Y. Hayakawa, et al., ISIJ Int. 59(2), 351 (2019).

R. Suehiro, Y. Hayakawa, and T. Takamiya, ISIJ Int. 59(2), 351 (2019).

L. Fan, Study on Texture Evolution and Secondary Recrystallization Behavior of Low Temperature Oriented-Silicon Steel (China Iron and Steel Research Institute, 2014).

M.W. Chase, NIST-JANAF Thermochemical Tables (American Chemical Society, Washington, 1998).

M. Yamaguchi, Jpn. Inst. Metals 72(9), 657–666 (2008).

M. Yamaguchi, Metall. Mater. Trans. A 42, 319 (2011).

H. Sawada, J. Haga, and K. Ushioda, Nippon Steel Sumitomo Metal Tech. Rep. 120, 15 (2018).

Q. Feng, J. Li, Y. Zeng, et al., J. Market. Res. 23, 5710 (2023).

M. Godec, M. Jenko, H.J. Grabke, et al., ISIJ Int. 39(7), 742 (1999).

T. Egami, and Y. Waseda, J. Non-Cryst. Solids 64(1–2), 113 (1984).

C.L. White, and W.A. Coghlan, Metall. Mater. Trans. A 8(9), 1403 (1977).

J.R. Rice, and J. Wang, Mater. Sci. Eng. A 107, 23 (1989).

Funding

The authors acknowledge the support from the National Natural Science Foundation of China (NSFC) (no. 52374316), the Fund of Education Department of Anhui Province (no. 2022AH050291), the Open Project Program of Anhui Province Key Laboratory of Metallurgical Engineering & Resources Re-cycling (Anhui University of Technology) (no. SKF21-04) and the Jiangxi Province Major Scientific and Technological Research and Development Special Funding Project (20213AAE01009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Hj., Shao, Kx., Qiao, Jl. et al. Influence Mechanism of Sn on 2.7%Si-0.5%Al Non-oriented Silicon Steel. JOM (2024). https://doi.org/10.1007/s11837-024-06549-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06549-8