Abstract

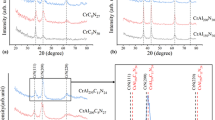

Using the ultrasonic surface rolling technique (USRT), a surface nanocrystalline layer was prepared on the CuTi alloy by adjusting the rolling depth. The phase composition, surface hardness, wear resistance, and corrosion resistance of the generated nanocrystalline layer were systematically characterized by using X-ray diffraction, scanning electron microscopy, and other testing methods. The results showed that the USRT did not change the surface phase of the CuTi alloy but refined the surface grains into nanocrystals. The rolling depth had a significant influence on the surface properties of the CuTi alloy. When the rolling depth was 0.15 mm, the overall performance of the sample’s surface was the best. The average grain size of the nanocrystalline layer was approximately 16.1 nm, and the surface hardness was increased from 257.68 HV0.1 to 322.7 HV0.1. The wear resistance and corrosion resistance of the alloy were significantly enhanced. The USRT provides a new method for preparing CuTi alloys with excellent surface properties.

Similar content being viewed by others

References

B. Rouxel, C. Cayron, J. Bornand, P. Sanders, and R.E. Logé, Mater. Des. 213, 110340 (2022).

W.J. Liu, X. Chen, T. Ahmad, C.Y. Zhou, and X.P. Xiao, Mater. Sci. Eng. A. 835, 142672 (2022).

L. Huang, Z.S. Cui, X.P. Meng, X.W. Zhang, X.Y. Zhang, X.P. Song, T. Ning, X. Zhu, L. Qing, and L. Zhou, Mater. Sci. Eng. A 823, 141581 (2021).

P. Dasic, M. Radovanovic, E. Assenova, and F. Franek, Ind. Lubr. Tribol. 5(6), 287 (2003).

H.P. Jost, Tribol. Lubr. Technol. 61(10), 18 (2005).

X.W. Shi, S. Zhang, Q. Zhou, J. Li, B.L. Zhu, L.J. Xu, and Q.L. Gao, Tungsten 5(1), 179 (2023).

C.Y. Liang, X.J. Jiang, R.L. Ji, B.E. Li, X.R. Zou, H.S. Wang, J.Z. Hao, and T. Yang, Rare Met. 40, 1164 (2021).

Z.B. Qin, Z. Wu, X.S. Zen, Q. Luo, L. Liu, W.J. Lu, and W.B. Hu, Corrosion 72(10), 1269 (2016).

A. Morales, O. Piamba, and J. Olaya, Coatings 9(11), 722 (2019).

M. Yuan, K. Yi, and X.Q. Huang, Jiangxi Metall. 28(02), 25 (2008).

Y. Jiang, P. Huang, Z.Q. Jiang, J. Hou, Z. Xu, E.H. Wu, and J. Li, Tungsten 5(4), 1 (2023).

J.B. Liu and X.H. Zhang, Mater. Manuf. Process. 36(10), 1208 (2021).

T.O. Olugbade, E.O. Olutomilola, and B.J. Olorunfemi, Corros. Rev. 40(3), 189 (2022).

M. Ran, Q. Wang, S. You, and H. Wang, Mater Charact 203, 113065 (2023).

X.X. Li, X. Wang, B.Q. Chen, M.Y. Gao, C. Jiang, H.X. Yuan, X.H. Zhang, and T.X. Liang, Vacuum 209, 111819 (2023).

B.Q. Chen, J.B. Liu, X.X. Li, W.Q. Chen, X.H. Zhang, and T.X. Liang, Surf. Topogr. 10(1), 015004 (2022).

P. Kumar, G.S. Mahobia, V. Singh, and K. Chattopadhyay, Int. J. Fatigue 166, 107289 (2023).

X.D. Chen, T.Y. Cui, S.Y. He, W.W. Chang, Y.Z. Shi, and Y.T. Lou, Coatings 13(2), 246 (2023).

C.S. Wang, R.F. Li, X.L. Bi, W.Y. Yuan, J.Y. Gu, J. Chen, M.J. Yan, and Z.Y. Zhang, J. Mater. Res. Technol. 22, 853 (2023).

M.Y. Li, J. Yang, B. Han, L.X. Song, P. Li, W.L. Dong, and X.X. Xue, Mater. Today Commun. 34, 105219 (2023).

X.P. Chen, L.F. Zhang, Y. Xiong, H. Yao, F.Z. Ren, and J. Zhang, Surf. Coat. Technol. 459, 129383 (2023).

T. Zhou, Y. Xiong, Z.G. Chen, X.Q. Zha, Y. Lu, T.T. He, and F.Z. Ren, Surf. Coat. Technol. 421, 127381 (2021).

C. Chen and H.J. Zhang, Surf. Coat. Technol. 423, 127615 (2021).

W.Q. Chen, G.M. Xu, Z.Y. Cui, J.T. Yu, X.H. Zhang, and C.M. Wang, Nonferrous Met. Sci. Eng. 12(6), 80 (2021).

Y. Li, Appl. Surf. Sci. 627, 157334 (2023).

Z.S. Cui, L. Huang, Q. Lie, X.P. Meng, Z. Xiao, and Z. Li, Metall. Eng. 7(3), 121 (2020).

A.L. Patterson, J. Am. Chem. Soc. 77(7), 2030 (1955).

A.T. Bozdana and N.N.Z. Gindy, Mater. Sci. Technol. 24(11), 1378 (2008).

S. Zhang, F. Wang, and P. Huang, Mater. Sci. Tech. 87(28), 176 (2021).

T.T. Xia, L.F. Zeng, X.H. Zhang, and B. Yang, Surf. Coat. Technol. 363, 390 (2019).

Acknowledgements

This study is supported by the Major science and technology R&D project of Jiangxi Province (Grant Number 20223AAG01009), the National Natural Science Foundation of China (Grant Number 51804138), the National Natural Science Foundation of Jiangxi Province (Grant Number 20192ACB20003), the Qingjiang Young Talents Support Program of Jiangxi University of Science and Technology (grant Number JXUSTQJYX2020014), the University Leading Talent Training Project of Jiangxi Province - Young Leading Talents (Grant Number zxh).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Jiang, C., Liu, T. et al. Effect of Ultrasonic Rolling Surface Technique on the Surface Microstructure and Properties of CuTi Alloys. JOM 76, 2807–2815 (2024). https://doi.org/10.1007/s11837-024-06436-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-024-06436-2