Abstract

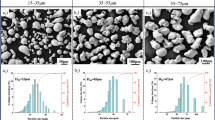

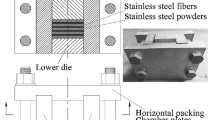

Copper powder and copper wire mesh were used as raw materials, and porous copper powder/mesh plates were prepared by pressing, rolling, and vacuum sintering. The plate morphology was observed by scanning electron microscopy. The air permeability of the porous plates was tested according to Darcy’s law, and uniaxial tensile tests were carried out on the porous plates to determine the influence of raw material mesh number and powder content on the porous plates’ permeability and tensile mechanical properties. The porous plate was fabricated into a restrictor of an aerostatic thrust bearing, and the static bearing performance of the bearing was tested on a bearing capacity testing platform. The results showed that the copper powder/mesh porous plate had a uniform pore distribution and a porosity range of 10% to 30%; the higher the porosity and lower the powder concentration, the better the performance was in terms of gas permeability. Tensile mechanical properties improved with decreasing porosity and increasing powder content. At a gas film thickness of 10 μm, the prepared gas hydrostatic thrust bearing could support a maximum load of 381.1 N.

Similar content being viewed by others

References

J.Y. Wang, H.P. Tang, P. Tan, and J. Zhou, Procedia Eng. 27, 737 (2012).

J. Deng and Z.Y. Zhou, JOM 75, 1294 (2023).

B. Lyu, J.Z. Chen, H.Z. Feng, C.Y. Liu, G. Ma, and M.M. Ma, Sci. Technol. Chem. Ind. 31, 82 (2023).

L.Y. Duan, Z.Y. Zhou, and B.B. Yao, Materials. https://doi.org/10.3390/ma11010156 (2018).

L.P. Lefebvre, J. Banhart, and D.C. Dunand, Adv. Eng. Mater. 10, 775 (2008).

N. Zou and Q.Z. Li, JOM 70, 650 (2018).

J. Capek and D. Vojtech, Mater. Sci. Eng. C 35, 21 (2014).

Y.J. Yi, M.J. Lee, S.J. Yun, M.H. Park, J.Y. Kim, J.W. Lee, and J.Y. Yun, Arch. Metall. Mater. 67, 1517 (2022).

Z.J. Li, T.W. Yang, Q.L. Jin, Y.H. Jiang, and R. Zhou, Rare Met. Mater. Eng. 43, 2609 (2014).

W. Liu and N. Canfield, J. Membr. Sci. 409–410, 113 (2012).

Z.Y. Zhou, H.J. Lu and J.W. Wang, J. South China Univ. Technol. Nat. Sci CNKI:SUN:HNLG.0.2020-04-006 (2020).

S. Mancin, C. Zilio, A. Cavallini, and L. Rossetto, Int. J. Heat Mass Transfer 53, 3121 (2010).

S.P. Zou, Z.P. Wan, L.S. Lu, and Y. Tang, Materials 9, 712 (2016).

C.Z. Li and Z.Y. Zhou, Powder Technol. https://doi.org/10.1016/J.POWTEC.2022.117205 (2022).

N.M. Brown and F.C. Lai, J. Fluids Eng. 128, 987 (2006).

Z.Z. Hou, Y.F. Dong, and J. Deng, J. Filtr. Sep. 26, 15 (2016).

C.Z. Li and Z.Y. Zhou, Adv. Eng. Mater. https://doi.org/10.1002/adem.202100585 (2021).

Q.B. Tan, P. Liu, C.L. Du, L.H. Wu, and G. He, Mater. Sci. Eng. A 527, 38 (2009).

S.L. Angioni, M. Meo and A, Smart Mater. Struct. https://doi.org/10.3390/ma11010156 (2011).

J.B. Zhang, D.L. Zou, N. Ta, and Z.S. Rao, Tribol. Int. 123, 385 (2018).

Acknowledgements

This work was supported by the Guangdong Provincial Key Areas R&D Program (No. 2019B090918003).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Y., Zhou, Z. Study on the Permeability and Mechanical Properties of Copper Powder/Mesh Porous Plates. JOM 76, 1235–1244 (2024). https://doi.org/10.1007/s11837-023-06273-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06273-9