Abstract

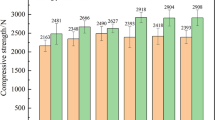

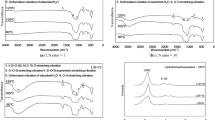

The novel one-step oxidation–volatilization process for separating MoO3 from pelletized MoS2 concentrate supported on a porous Al2O3-SiO2 skeleton has been demonstrated to have superior diffusion efficiency compared to the traditional two-step oxidative roasting-sublimation approach. Optimal control of pellet phase and micro-structure evolutions is crucial for maintaining a stable and breathable pellet bed throughout the roasting process, which is essential for industrial application of the new process. This work determined the phase transformations of MoS2 concentrate pellets during roasting, revealed the formation mechanisms of mullite whiskers from MoS2-Al2O3-SiO2 system and thus achieved toughening control of roasted MoS2 concentrate pellets with temperature programmed roasting (TPR). It is found that the intermediate product Al2(MoO4)3 can induce the low-temperature formation of mullite whisker. With TPR, the volatilization rate of molybdenum is 97.2%, and the compressive strength of mullite pellets reach 124.8 N. This study puts forward a feasible route with industrial significance.

Similar content being viewed by others

References

J. Carper, Libr. J. 124, 192 (1999).

P. Jarosz, JOM 65, 1615 (2013).

M.L. Parucker, A.N. Klein, C. Binder, W. Ristow Junior, and R. Binder, Mater. Res.-Ibero-Am. J. Mater. 17, 180 (2014).

W. Wang, C. Liu, D. Zhou, L. Yang, J. Zhou, and D. Yang, J. Alloys Compd. 792, 230 (2019).

I.Y. Gudkova, A.S. Vusikhis, and D.B. Lempert, Russ. Chem. Bull. 65, 2396 (2016).

C. Li, F. Wang, X. Hao, X. Ding, H. Zhang, M. Ling, J. Zhou, Y. Li, W. Fan, and W. Sun, Int. Geol. Rev. 54, 1093 (2012).

T. Outteridge, N. Kinsman, G. Ronchi, and H. Mohrbacher, Adv. Manuf. 8, 35 (2020).

J. Leitner, C. Hauler, F. Oeters, L.Y. Zhang, and S. Eriksson, Stahl Eisen 120, 69 (2000).

B. Liu, B. Zhang, G. Han, M. Wang, Y. Huang, S. Su, Y. Xue, and Y. Wang, Resour. Conserv. Recycl. 181, 106232 (2022).

L.I. Leont’Ev, L.A. Smirnov, V.I. Zhuchkov, A.V. Zhdanov, V.Y. Dashevskii, and S.A. Gurova, Metallurgist 59, 1001 (2016).

Q. Zhu, M. Xie, X. Shang, G. An, J. Sun, N. Wang, S. Xi, C. Bu, and J. Zhang, Metals (Basel) 10, 279 (2020).

E.I. Kharin, B.D. Khalezov, N.A. Vatolin, and E.A. Zelenin, Theor. Found. Chem. Eng. 47, 476 (2013).

L. Wang, G. Zhang, J. Wang, and K. Chou, Metall. Mater. Trans. B-Proc. Metall. Mater. Proc. Sci. 47, 2421 (2016).

T.A. Lasheen, M.E. El-Ahmady, H.B. Hassib, and A.S. Helal, Miner. Process. Extr. Metall. Rev. 36, 145 (2015).

M. Wang, and X. Wang, Hydrometallurgy 102, 50 (2010).

P.V. Aleksandrov, A.S. Medvedev, M.F. Milovanov, V.A. Imideev, S.A. Kotova, and D.O. Moskovskikh, Int. J. Miner. Process. 161, 13 (2017).

L. Wang, M. Li, Z. Xue, G. Zhang, and A. Huang, Trans. Indian Inst. Met. 74, 1469 (2021).

I. Wilkomirsky, A. Otero, and E. Balladares, Metall. Mater Trans. B-Proc. Metall. Mater. Proc. Sci. 41, 63 (2010).

H. Sun, G. Li, J. Yu, J. Luo, M. Rao, Z. Peng, and T. Jiang, Powder Technol. 345, 338 (2019).

G. Li, Z. You, H. Sun, R. Sun, Z. Peng, Y. Zhang, and T. Jiang, Metals (Basel) 6, 282 (2016).

H. Sun, G. Li, J. Wang, Q. Bu, J. Luo, M. Rao, Z. Peng, and T. Jiang, J. Clean. Prod. 284, 747 (2021).

G. Li, Q. Bu, H. Sun, D. Shi, J. Luo, M. Rao, Z. Peng, and T. Jiang, ACS Sustain. Chem. Eng. 8, 7290 (2020).

Z. Zhang, W. Yan, N. Li, Y. Li, W. Zhou, and B. Han, Ceram. Int. 45, 17268 (2019).

Acknowledgements

This work was supported by the Key Projects of the National Natural Science Foundation of China (No. 52234008).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, G., Huang, J., Sun, H. et al. Phase and Structure Optimizations of MoS2 Concentrate Pellets with Al2O3-SiO2 Additives During Oxidative and Volatilizing Roasting Process. JOM 75, 5167–5175 (2023). https://doi.org/10.1007/s11837-023-05968-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05968-3