Abstract

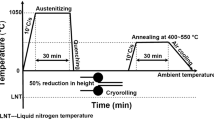

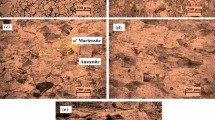

Low-carbon steel has been widely used in a variety of industries, but its limited strength makes it difficult to develop its potential applications. The current work aims to produce ultrafine-grains in low-carbon steel using cryorolling at various thickness reductions of 50%, 60%, 70%, 80%, and 90%, and to investigate its impact on the microstructure, mechanical properties, and corrosion behavior. Hardness and tensile strength increased with reduction, with the highest values attained at 90% with 208.5 Hv and 826.5 MPa, respectively. The sample cryorolled at 90% has the smallest crystallite size (38.16 nm) and the highest lattice strain (20.58 × 10−4). Low-angle grain boundaries increase as the thickness decreases, whereas high-angle grain boundaries show a different trend. Corrosion resistance decreases with thickness reduction, with the highest corrosion rate (18.912 mm/year) obtained for the sample cryorolled at 90%.

Similar content being viewed by others

References

M. Arslanhafeez, M. Usman, M.A. Arshada, and M. Adeelumar, Cryst. 508, 1 (2020).

C.A. Suski, D.C. Cesar Edil, and G.M. Julio Cesar, J. Mater. Res. 25, 1 (2022).

E. Razizadeh, A. Mani, and M. Kazeminezhad, Mater. Sci. Eng. A. 515, 162 (2009).

Q. Yuan, G. Xu, M. Liu, S. Liu, and H. Hu, Trans. Indian Inst. Met. T. 1 (2018).

N. Tsuji, Y. Ito, Y. Saito, and Y. Minamino, Scr. Mater. 47, 893 (2002).

J.T. Shi, L.-G. Hou, J.-R. Zuo, L.-Z. Zuang, and J.-S. Zhang, Int. J. Miner. Metall. 24, 638 (2017).

S.A. Zakaria, A.S. Anasyida, H. Zuhailawati, B.K. Dhindaw, N.A. Jabit, and A. Ismail, Trans. Nonferrous Met. Soc. China. 31, 2949 (2021).

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe, Mater. Sci. Eng. A. 527, 2738 (2010).

N. Peranio, Y.J. Li, F. Roters, and D. Raabe, Mater. Sci. Eng. A. 527, 4161 (2010).

Y. Xiong, T. He, H. Li, Y. Lu, F. Ren, and A.A. Volinsky, Mater. Sci. Eng. A. 703, 68 (2017).

P. Mallick, N. Tewary, S.K. Ghosh, and P.P. Chattopadhyay, Mater. Charact. 133, 77 (2017).

B. Roy, R. Kumar, and J. Das, Mater. Sci. Eng. A. 631, 241 (2015).

R. Ueji, N. Tsuji, Y. Minamino, and Y. Koizumi, Sci. Technol. Adv. Mater. 5, 153 (2004).

P. Li, J. Li, Q. Meng, W. Hu, and D. Xu, J. Alloys Compd. 578, 320 (2013).

Y. Xiong, T. He, J. Wang, Y. Lu, L. Chen, F. Ren, Y. Liu, and A.A. Volinsky, Mater. Des. 88, 398 (2015).

Y. Xiong, T. He, Z. Guo, H. He, F. Ren, and A.A. Volinsky, Mater. Sci. Eng. A. 563, 163 (2013).

D. Singh, R. Jayaganthan, P. Nageswara Rao, A. Kumar, and D. Venkateswarlu, Mater. Today. 4, 7609 (2017).

R. Jayaganthan, H.G. Brokmeier, B. Schwebke, and S.K. Panigrahi, J. Alloys Compd. 496, 183 (2010).

S. Goel, N. Keskar, R. Jayaganthan, I.V. Singh, D. Srivastava, G.K. Key, and N. Saibaba, Mater. Sci. Eng. A. 603, 23 (2014).

K.S.V.B.R. Krishna, K. Chandra Sekhar, R. Tejas, N. Naga Krishna, K. Sivaprasad, R. Narayanasamy, and K. Venkateswarlu, Mater. Des. 67, 107 (2015).

D. Guo, M. Li, Y. Shi, Z. Zhang, T. Ma, H. Zhang, and X. Zhang, Mater. Sci. Eng. A. 558, 611 (2012).

D. Singh, R.P. Nageswara, and R. Jayaganthan, Int. J. Miner. Metall. 20, 759 (2013).

Z. Xu, M. Liu, Z. Jia, and H.J. Roven, J. Alloys Compd. 695, 827 (2017).

M. Yadollahpour, H. Hosseini-Toudeshky, and F. Karimzadeh, JOM. 68, 1446 (2016).

N. Rangaraju, T. Raghuram, B.V. Krishna, K.P. Rao, and P. Venugopal, Mater. Sci. Eng. A. 398, 246 (2005).

J. Callister, D. William, Fundamentals of Meterial Science and engineering. (United State of America 2005), pp 536-538.

D. Gendy, Carbon Steel Handbook (California, Palo alto, 2007), pp35–38.

V.M. Segal, S. Ferrasse, and F. Alford, Mater. Sci. Eng. A. 422, 321 (2006).

Y. Xiong, Y. Yue, Y. Lu, T. He, M. Fan, F. Ren, and W. Cao, Mater. Sci. Eng. A. 709, 270 (2018).

M. Hiroyuki, Mater. Trans. 57, 559 (2016).

Y. Estrin, and A. Vinogradov, Acta Mater. 61, 782 (2013).

G. Shit, P. Bhaskar, S. Ningshen, A. Dasgupta, U.K. Mudali, and A.K. Bhaduri, AIP Conf. Proc. 1832, 030020 (2017).

P. Wang, J. Zhao, L. Ma, X. Cheng, and X. Li, Mater. Charact. 179, 111385 (2021).

M. Hasegawa, and M. Osawa, Corrosion 40(7), 371 (1984).

Acknowledgement

The authors gratefully acknowledge the financial assistance provided by JICA AunSeed-Net. This study was also supported by a MYTRIBOS Industrial Grant, Grant No. 304 /PBAHAN /6050471 /M171.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no disclosures to declare

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zakaria, S.A., Motham, K., Anasyida, A.S. et al. Microstructure, Mechanical Properties, and Corrosion Behaviour of Cryorolled Low-Carbon Steel at Different Thickness Reductions. JOM 75, 3900–3910 (2023). https://doi.org/10.1007/s11837-023-05953-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05953-w