Abstract

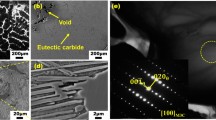

The dissolution behavior and dislocation proliferation of carbides during the quenching process of GCr15 steel are studied respectively under a single temperature field and a magnetic-thermal coupling field. The morphology of carbides was observed by using scanning electron microscopy, the hardness of specimens was tested by Vickers hardness tester, the surface residual stress of specimens was tested by XRD strain gauge, and the dislocation density of specimens was tested by XRD diffractometer under both single temperature field and magnetic-thermal coupling field. The results show that the pulsed magnetic field is beneficial to the dissolution of carbides during the quenching austenite transition of GCr15 steel, and the number of undissolved carbide particles from 68.4 × 10−2 μm−2 in a single temperature field decreases to 38 × 10−2 μm−2, and the dislocation density increases from 296.4 × 1010 m−2 under a single temperature field to 358.8 × 1010 m−2 with an 20.1% increase by applying pulsed magnetic field. From the kinetics theory, it is believed that the frequency of carbon atoms migrating to the gap position increases; thereby the diffusion coefficient D0 increases, and the diffusion of carbon atoms in the matrix is accelerated by employing a pulsed magnetic field.

Similar content being viewed by others

Data and Code Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Z. Zuchang, Y. Yitao, and Z. Wenwei, Heat Treatm. Technol. Equipm. 43(02), 63 https://doi.org/10.19382/j.cnki.1673-4971.2022.02.011 (2022).

D.A. Molodov and P.J. Konijnenberg, Scripta Mater. 54, 977 https://doi.org/10.1016/j.scriptamat.2005.11.038 (2006).

J.Y. Song, Y.D. Zhang, X. Zhao, and L. Zuo, J. Mater. Sci. 43, 0108 https://doi.org/10.1007/s10853-008-2944-z (2008).

A. Akhbarizadeh, K. Amini, and S. Javadpour, Mater. Des. 35, 484 https://doi.org/10.1016/J.MATDES.2011.09.015 (2012).

V. Alshits, E. Darinskaya, T. Perekalina, and A. Urusovskaya, Fiz. Tverd. Tela 29, 467 (1987).

B. Nawaz, X. Long, Z. Yang, J. Zhao, F. Zhang, and J. Li, Mater. Sci. Eng. A 759, 11 https://doi.org/10.1016/j.msea.2019.05.023 (2019).

L. Ma, W. Zhao, Z. Liang, X. Wang, L. Xie, L. Jiao, and T. Zhou, Mater. Sci. Eng. A 609, 16 https://doi.org/10.1016/j.msea.2014.04.100 (2014).

C. Qian, K. Li, S.S. Rui, M. Hou, X. Zhang, Y. Wu, and Z. Cai, J. Alloys Comp. 881, 160471 https://doi.org/10.1016/j.jallcom.2021.160471 (2021).

M.M. Mahmoud and M. Thumm, J. Eur. Ceram. Soc. 35(10), 2915 (2015).

G.K. Williamson and R.E. Smallman, Philos. Mag. A J. Theor. Exp. Appl. Phys. 1(1), 34 https://doi.org/10.1080/14786435608238074 (1956).

V. Biju, N. Sugathan, and V. Vrinda, J. Mater. Sci. 43, 1175 https://doi.org/10.1007/s10853-007-2300-8 (2008).

X. Tan, Y. Xu, X. Yang, and D. Wu, Mater. Sci. Eng. A 589, 101 https://doi.org/10.1016/j.msea.2013.09.063 (2014).

H.Y. Wu, D.X. Han, and Y. Du, Mater. Today Commun. 30, 103152 (2022).

Y. Yao, L. Zhang, and H. Wang, Relationship between hardness and carbon content of carbon steel quenched martensite. HTM 39(8), 136–138 (2014).

C. Sun, Fu. Pai-Xian, and X.-P. Ma, J. Market. Res. 9(4), 7701 (2020).

S.N. Postnikov, Electrophysical and Electrochemical Phenomena in Friction, Cutting, and Lubrication (Van Nostrand Reinhold, NY, 1978).

Y.N. Wang, S.J. Chen, and X.C. Dong, Dislocation Theory and its Applications (Metallurgical Industry Press, Beijing, 2007) (in Chinese).

A. Meyer, Phys. Rev. B 66(13), 134205 (2002).

P.J. Ferreira and J.B. Vander Sande, Scripta Mater. 41(2), 117–123 https://doi.org/10.1016/S1359-6462(99)00121-9 (1999).

B. Qingwei, M. Yonglin, X. Shuqing, Y. Wenxia, and C. Chongyi, Mater. Rev. 35(20), 20143 (2021).

X. Ren, G.Q. Chen, and W.L. Zhou, J. Alloy. Compd. 472(1–2), 525 (2009).

Funding

Natural Science Foundation of Inner Mongolia Autonomous Region (2022MS05046), Inner Mongolia Autonomous Region Science and Technology Program Project (2021GG0047).

Author information

Authors and Affiliations

Contributions

XG: Investigation, Data curation, Writing—original draft., SL: Investigation. XS: Formal analysis. MY: Methodology. LY and CZ: Data curation, Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, G., Shen, L., Xing, S. et al. Effect of Pulsed Magnetic Field on Quenched Heat Treatment of GCr15 Steel. JOM 75, 2256–2264 (2023). https://doi.org/10.1007/s11837-023-05834-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05834-2