Abstract

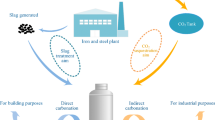

A sustainable method for Ti, Al, and Mg recovery from titanium-bearing blast furnace slag (TBBFS) coupled with CO2 sequestration by leaching residue is proposed. The results show that the original mineral phase of the TBBFS could be destroyed by ammonium sulfate roasting, in which the valuable metals were converted to sulfates. Subsequently, Ti, Al, and Mg in the roasting slag were effectively extracted with dilute sulfuric acid leaching. The Ti, Al, and Mg in the solution could be separated and recovered by the stepwise hydrolysis method. The leaching residue was used for CO2 sequestration through the carbonation reaction. Under optimal conditions, the fractional conversion of calcium sulfate reached 98.83%, while an ammonium sulfate product was obtained. The proposed process achieves not only the recovery of Ti, Al, and Mg from the TBBFS but also the recycling of ammonia and sulfur based on the carbonation reaction of the leaching residue.

Similar content being viewed by others

References

M. Zhou, T. Jiang, S. Yang, and X. Xue, Int. J. Miner. Process. 142, 125. https://doi.org/10.1016/j.minpro.2015.04.019 (2015).

J. Yu, N. Hu, H. Xiao, P. Gao, and Y. Sun, Powder Technol. 385, 83. https://doi.org/10.1016/j.powtec.2021.02.038 (2021).

M. Zhou, S.T. Yang, T. Jiang, and X.X. Xue, JOM-US 67, 1203. https://doi.org/10.1007/s11837-015-1326-7 (2015).

G. Li, X.W. Lv, Z. Zheng, J.W. Ling, and G.B. Qiu, JOM-US 73, 316. https://doi.org/10.1007/s11837-020-04476-y (2021).

W. Zhang, T. Zhang, T. Li, G. Lv, and X. Cao, J. Environ. Chem. Eng. 9, 104897. https://doi.org/10.1016/j.jece.2020.104897 (2021).

W. Zhao, M. Chu, H. Wang, Z. Liu, J. Tang, and Z. Ying, Powder Technol. 342, 214. https://doi.org/10.1016/j.powtec.2018.09.069 (2019).

G. Fan, M. Wang, J. Dang, R. Zhang, Z. Lv, W. He, and X. Lv, Waste Manag. 120, 626. https://doi.org/10.1016/j.wasman.2020.10.024 (2021).

J. Ju, Y. Feng, H. Li, and C. Xu, Asia-Pac. J. Chem. Eng. 17, e2777. https://doi.org/10.1002/apj.2777 (2022).

C. Wang, Y. Lei, W. Ma, and P. Qiu, J. Hazard. Mater. 401, 123446. https://doi.org/10.1016/j.jhazmat.2020.123446 (2021).

S.K. Tripathy, J. Dasu, Y.R. Murthy, G. Kapure, A.R. Pal, and L.O. Filippov, J. Clean. Prod. 262, 121354. https://doi.org/10.1016/j.jclepro.2020.121354 (2020).

L. Wang, W. Liu, J. Hu, Q. Liu, H. Yue, B. Liang, G. Zhang, D. Luo, H. Xie, and C. Li, Chin. J. Chem. Eng. 26, 583. https://doi.org/10.1016/j.cjche.2017.06.012 (2018).

F. Zheng, Y. Guo, G. Qiu, F. Chen, S. Wang, Y. Sui, T. Jiang, and L. Yang, J. Hazard. Mater. 344, 490. https://doi.org/10.1016/j.jhazmat.2017.10.042 (2018).

Z. Li, Y. Lei, W. Ma, Y. Zhang, and C. Wang, Sep. Purif. Technol. 265, 118473. https://doi.org/10.1016/j.seppur.2021.118473 (2021).

H. Jiao, D. Tian, S. Wang, J. Zhu, and S. Jiao, J. Electrochem. Soc. 164, D511. https://doi.org/10.1149/2.0221709jes (2017).

M. Lan, P. Rongxun, Y. Shaoli, and L. Binbin, Rare Metal. Mat. Eng. 47, 1411. https://doi.org/10.1016/S1875-5372(18)30143-7 (2018).

Y. Du, J. Gao, X. Lan, and Z. Guo, J. Eur. Ceram. Soc. 42, 2055. https://doi.org/10.1016/j.jeurceramsoc.2021.12.047 (2022).

M. Hu, R. Wei, Z. Qu, F. Yin, Y. Xu, and Q. Deng, Green Process. Synth. 5, 195. https://doi.org/10.1515/gps-2015-0092 (2016).

X. Lei and X. Xue, Trans. Nonferr. Metal. Soc. 20, 2294. https://doi.org/10.1016/S1003-6326(10)60643-7 (2010).

X.F. Lei and X.X. Xue, Mater. Chem. Phys. 112, 928. https://doi.org/10.1016/j.matchemphys.2008.06.065 (2008).

Y. Wang, T. Qi, J. Chu, and W. Zhao, Rare Met. 29, 162. https://doi.org/10.1007/s12598-010-0028-0 (2010).

X. Liu, G. Gai, Y. Yang, Z. Sui, L. Li, and J. Fu, Int. J. Min. Sci. Technol. 18, 275. https://doi.org/10.1016/S1006-1266(08)60058-9 (2008).

Y. Lei, L. Sun, W. Ma, X. Ma, J. Wu, S. Li, and K. Morita, J. Alloys Compd. 769, 983. https://doi.org/10.1016/j.jallcom.2018.08.077 (2018).

S. Zhu, J. Hu, C. Zhang, S. Li, and N. An, J. Mater. Res. Technol. https://doi.org/10.1016/j.jmrt.2022.06.038 (2022).

F. Cui, W. Mu, S. Wang, H. Xin, Q. Xu, Y. Zhai, and S. Luo, Miner. Eng. 123, 104. https://doi.org/10.1016/j.mineng.2018.04.013 (2018).

G. Zhang, T. Hu, W. Liao, and X. Ma, J. Environ. Chem. Eng. 9, 105332. https://doi.org/10.1016/j.jece.2021.105332 (2021).

J. Ju, Y. Feng, H. Li, R. Wu, and B. Wang, J. Environ. Chem. Eng. 10, 108153. https://doi.org/10.1016/j.jece.2022.108153 (2022).

J. Li, Z. Chen, B. Shen, Z. Xu, and Y. Zhang, J. Clean. Prod. 140, 1148. https://doi.org/10.1016/j.jclepro.2016.10.050 (2017).

X.Y. Shen, H.M. Shao, J.W. Ding, Y. Liu, H.M. Gu, and Y.C. Zhai, Int. J. Min. Met. Mater. 27, 1471. https://doi.org/10.1007/s12613-020-2015-2 (2020).

G. Zhang, D. Luo, C. Deng, L. Lv, B. Liang, and C. Li, J. Alloys Compd. 742, 504. https://doi.org/10.1016/j.jallcom.2018.01.300 (2018).

Q. Lin, G. Zhang, K. Wang, D. Luo, S. Tang, and H. Yue, Chin. J. Chem. Eng. https://doi.org/10.1016/j.cjche.2021.05.035 (2021).

F. Liu, F. Chen, L. Wang, S. Ma, X. Wan, and J. Wang, Hydrometallurgy 203, 105626. https://doi.org/10.1016/j.hydromet.2021.105626 (2021).

Y. Tang, X. Qu, B. Zhang, Y. Zhao, H. Xie, J. Zhao, Z. Ning, P. Xing, and H. Yin, J. Clean. Prod. 279, 123633. https://doi.org/10.1016/j.jclepro.2020.123633 (2021).

O. Rahmani, J. CO2 Util. 24, 321. https://doi.org/10.1016/j.jcou.2018.01.020 (2018).

J. Hu, W. Liu, L. Wang, Q. Liu, F. Chen, H. Yue, B. Liang, L. Lü, Y. Wang, G. Zhang, and C. Li, J. Energy Chem. 26, 927. https://doi.org/10.1016/j.jechem.2017.06.009 (2017).

S. Lee, J.-W. Kim, S. Chae, J.-H. Bang, and S.-W. Lee, J. CO2 Util. 16, 336. https://doi.org/10.1016/j.jcou.2016.09.003 (2016).

Q. Liu, W. Liu, J. Hu, L. Wang, J. Gao, B. Liang, H. Yue, G. Zhang, D. Luo, and C. Li, J. Clean. Prod. 197, 242. https://doi.org/10.1016/j.jclepro.2018.06.150 (2018).

X. Xu, W. Liu, G. Chu, G. Zhang, D. Luo, H. Yue, B. Liang, and C. Li, Hydrometallurgy 184, 151. https://doi.org/10.1016/j.hydromet.2019.01.004 (2019).

K.S. Lackner, Science 300, 1677. https://doi.org/10.1126/science.1079033 (2003).

E.I. Nduagu, J. Highfield, J. Chen, and R. Zevenhoven, RSC Adv. 4, 64494. https://doi.org/10.1039/C4RA08925A (2014).

H. Sheng, L. Lv, B. Liang, C. Li, B. Yuan, L. Ye, H. Yue, C. Liu, Y. Wang, J. Zhu, and H. Xie, Environ. Earth Sci. 73, 6871. https://doi.org/10.1007/s12665-015-4412-9 (2015).

O. Rahmani, J. CO2 Util. 35, 265–271. https://doi.org/10.1016/j.jcou.2019.10.005 (2020).

W. Liu, J. Hu, Q. Liu, and C. Li, Chin. J. Chem. Ind. Eng. Progress 40, 4624. https://doi.org/10.16085/j.issn.1000-6613.2020-1773 (2021).

Z. Bian, Y. Feng, and H. Li, Trans. Nonferr. Metal. Soc. 30, 2836. https://doi.org/10.1016/S1003-6326(20)65425-5 (2020).

H. Wu, Y. Feng, H. Li, S. He, and Z. Bian, Sci. Total Environ. 691, 9. https://doi.org/10.1016/j.scitotenv.2019.07.080 (2019).

Acknowledgements

This research was supported by China Ocean Mineral Resources R&D Association under Grant Nos. JS-KTHT-2019-01 and DY135-B2-15.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ju, J., Feng, Y., Li, H. et al. A Sustainable Method for Ti, Al and Mg Recovery from Titanium-Bearing Blast Furnace Slag Coupled with CO2 Sequestration by Leaching Residue. JOM 75, 358–369 (2023). https://doi.org/10.1007/s11837-022-05484-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05484-w