Abstract

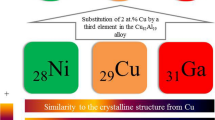

Cu-20Ni-20Mn-xGa (x = 1, 5 wt.%) alloys with high strength and elasticity were prepared and tested for corrosion properties in 3.5 wt.% NaCl solution. The hardness, tensile strength, elongation, and annual corrosion rate of the Cu-20Ni-20Mn-1 Ga alloy reached 1368 MPa, 442 HV, 8.63%, and 0.0262 mm/year, respectively, while those of Cu-20Ni-20Mn-5 Ga alloy were 1278 MPa, 428 HV, 2.5%, and 0.0119 mm/year, respectively. The excellent mechanical properties were attributed to the nanoscale NiMn phase which can strengthen the copper matrix. In addition to grain refinement, the addition of Ga also reduced the cathodic current. Also, the corrosion products of the two alloys in 3.5 wt.% NaCl solution were mainly oxides and chlorides. The Cu-20Ni-20Mn-5 Ga showed better corrosion resistance with more gallium-rich oxides in the corrosion product film to resist corrosion.

Similar content being viewed by others

References

S.H. Lo, W.M. Gibbon, and R.S. Hollingshead, JMatS 22, 3293 (1987).

L. Chen, D. Fu, and M. Chen, JMatS 55, 13398 (2020).

S. Nourbakhsh, and J. Nutting, JMatS 14, 2642 (1979).

J.L. Liu, X.M. Huang, G.H. Li, G.M. Cai, H.S. Liu, and Z.P. Jin, JMatS 53, 7809 (2018).

J. Lemus-Ruiz, L. Ceja-Cárdenas, J.A. Verduzco, and O. Flores, JMatS 43, 6296 (2008).

K.L. Lv, Z.Y. Xie, H.S. Liu, G.M. Cai, and Z.P. Jin, JMatS 50, 7238 (2015).

S. Hu, L. Liu, Y. Cui, Y. Li, and F. Wang, Corros. Sci. 146, 202 (2019).

R. Johnsen, T. Lange, G. Stenerud, and J.S. Olsen, Corros. Sci. 142, 45–55 (2018).

X. Wu, J. Zha, and M.A.G. Koffas, Curr. Opin. Food Sci. 32, 9 (2020).

G. Chunlei, L. Xuefeng, H. Haiyou, and X. Jianxin, Mat. Sci. Eng. A. 579, 202 (2013).

H. Wei, Y.-H. Wei, L.-F. Hou, and N. Dang, Corros. Sci. 111, 382 (2016).

Y. Wang, Y. Niu, G. Wang, Y. Sun, and C. Liu, J. Alloys Compd. 778, 691 (2019).

X. Guoliang, W. Qiangsong, M. Xujun, X. Baiqing, and P. Lijun, Mat. Sci. Eng. A. 558, 326 (2012).

X. Lu, Y.-W. Liu, H.-T. Zhao, C. Pan, Z.-Y. Wang, and T. Nonferr, Metal. Soc. 31, 703 (2021).

Y. Fu, J. Li, H. Luo, C. Du, and X. Li, J. Mater. Sci. Technol. 80, 217 (2021).

J. Liu, S. Yang, W. Xia, X. Jiang, and C. Gui, J. Alloys Compd. 654, 63 (2016).

L. Shao, G. Xie, X. Liu, Y. Wu, J. Yu, and Y. Wang, Corros. Sci. 163, 108253 (2020).

W.-B. Xie, Q.-S. Wang, X.-J. Mi, G.-L. Xie, D.-M. Liu, X.-C. Gao, Y. Li, and T. Nonferr, Metal. Soc. 25, 3247 (2015).

J. Ren, E. Guo, X. Wang, H. Kang, Z. Chen, and T. Wang, Materials (Basel) 12, 3686 (2019).

M.F. Wang, D.H. Xiao, B.R. Sun, and W.S. Liu, J. Alloys Compd. 776, 172 (2019).

C. Wang, Y. Gong, B.V. Cunning, S. Lee, Q. Le, S.R. Joshi, O. Buyukcakir, H. Zhang, W.K. Seong, M. Huang, M. Wang, J. Lee, G.H. Kim, and R.S. Ruoff, Sci Adv 7, 3767 (2021).

A. NACE, ASTM International (ASTMG31–12a (2012)).

Rashmi and P.K.C. Pillai, JMatS, 20, 2275–2279 (1985).

C.-H. Chang, T.-C. Huang, C.-W. Peng, T.-C. Yeh, H.-I. Lu, W.-I. Hung, C.-J. Weng, T.-I. Yang, and J.-M. Yeh, Carbon 50, 5044 (2012).

F. Muktepavela, G. Bakradze, and V. Sursaeva, JMatS 43, 3848 (2008).

H. Jin, Z. Nie, L. Wang, D. Cong, C. Tan, H. Cai, and Y. Wang, Intermetallics 131, 107128 (2021).

M.-X. Wang, H. Zhu, G.-J. Yang, K. Liu, J.-F. Li, and L.-T. Kong, Mater. Design. 198, 109359 (2021).

K. Nagato, K. Shintani, T. Shimura, N. Shikazono, and M. Nakao, J. Electrochem. Soc. 166, F144–F148 (2019).

T. Zhao, S. Wang, Z. Liu, C. Du, and X. Li, Corros. Sci. 179, 109176 (2021).

Z. Xiao, Z. Li, A. Zhu, Y. Zhao, J. Chen, and Y. Zhu, Corros. Sci. 76, 42 (2013).

H. Nady, N.H. Helal, M.M. El-Rabiee, and W.A. Badawy, MCP 134, 945 (2012).

L. Núñez, E. Reguera, F. Corvo, E. González, and C. Vazquez, Corros. Sci. 47, 461 (2005).

A. Drach, I. Tsukrov, J. DeCew, J. Aufrecht, A. Grohbauer, and U. Hofmann, Corros. Sci. 76, 453 (2013).

ŽZ. Tasić, M.B.P. Mihajlović, M.B. Radovanović, A.T. Simonović, and M.M. Antonijević, JMoSt 1159, 46 (2018).

S. Chen, and D. Zhang, Corros. Sci. 136, 275 (2018).

X. Zhang, S.O. Pehkonen, N. Kocherginsky, and G.A. Ellis, Corros. Sci. 44(11), 2507 (2002).

M. Wang, M. Song, G.S. Was, and J.L. Nelson, Corros. Sci. 160, 108168 (2019).

A.A. El-Moneim, A. Gebert, M. Uhlemann, O. Gutfleisch, and L. Schultz, Corros. Sci. 44, 1857 (2002).

M. Srinivas, S.K. Adapaka, and L. Neelakantan, J. Alloys Compd. 683, 647 (2016).

X. Wang, Z. Chen, E. Guo, X. Liu, H. Kang, and T. Wang, J. Alloys Compd. 863, 158762 (2021).

L. Romero-Resendiz, J.M. Cabrera, S. Elizalde, V. Amigó-Borrás, I.A. Figueroa, and G. Gonzalez, J. Market. Res. 18, 1281 (2022).

W.B. Xie, Q.S. Wang, G.L. Xie, X.J. Mi, D.M. Liu, X.C. Gao, and Y. Li, MSF 850, 773 (2016).

N. Saikrishna, G.P.K. Reddy, B. Munirathinam, and B.R. Sunil, J. Magnes. Alloys 4(1), 68 (2016).

G.R. Argade, K. Kandasamy, S.K. Panigrahi, and R.S. Mishra, Corros. Sci. 58, 321 (2012).

A. Balyanov, Scripta Mater. 51, 225 (2004).

H. Miyamoto, K. Harada, T. Mimaki, A. Vinogradov, and S. Hashimoto, Corros. Sci. 50, 1215 (2008).

M.T. Lee, H. Liu, and D. Brandell, Batteries Supercaps 3, 1370 (2020).

Y. Zhang, Z. Xiao, Y. Zhao, Z. Li, Y. Xing, and K. Zhou, MCP 199, 54 (2017).

M.R. Nellist, F.A. Laskowski, F. Lin, T.J. Mills, and S.W. Boettcher, Acc. Chem. Res. 49, 733 (2016).

J. Zhang, B. Jiang, Q. Yang, D. Huang, A. Tang, F. Pan, and Q. Han, J. Alloys Compd. 849, 156619 (2020).

K.D. Ralston, and N. Birbilis, Corrosion 66(7), 075005 (2010).

J. Kubasek, D. Vojtech, J. Lipov, and T. Ruml, Mater Sci Eng C Mater Biol Appl 33, 2421 (2013).

Acknowledgements

This work is supported by the National Key R&D Program of China (No. 2021YFB3501000), National Natural Science Foundation of China (No. 51701241), National Defense Pre-Research Foundation of China (No. 61402100105), the China Postdoctoral Science Foundation (No. 2018T110838) and Natural Science Foundation of Hunan Province (No. 2018JJ3647).

Funding

Funding was provided by National Key R&D Program of China, (Grant No. 2021YFB3501000), Shen Gong.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xiong, Y., Jiang, D., Xu, Z. et al. Microstructure and Corrosion Behaviors of High-Strength and High-Elasticity Cu-20Ni-20Mn-xGa Alloys. JOM 74, 4258–4270 (2022). https://doi.org/10.1007/s11837-022-05445-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05445-3